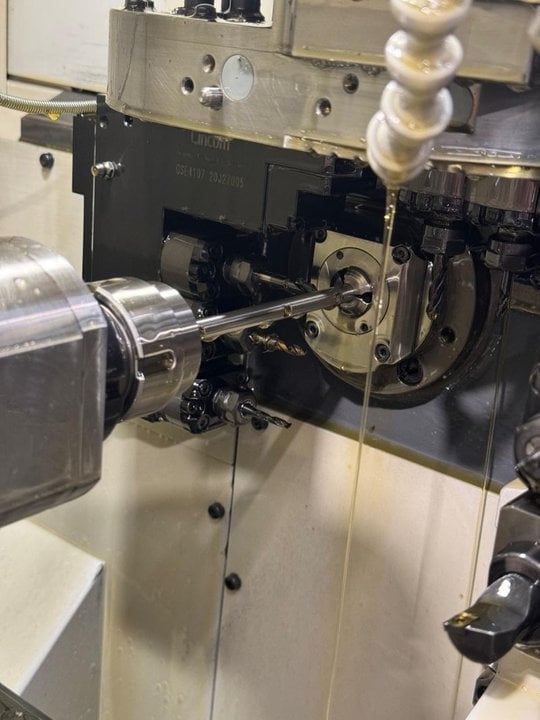

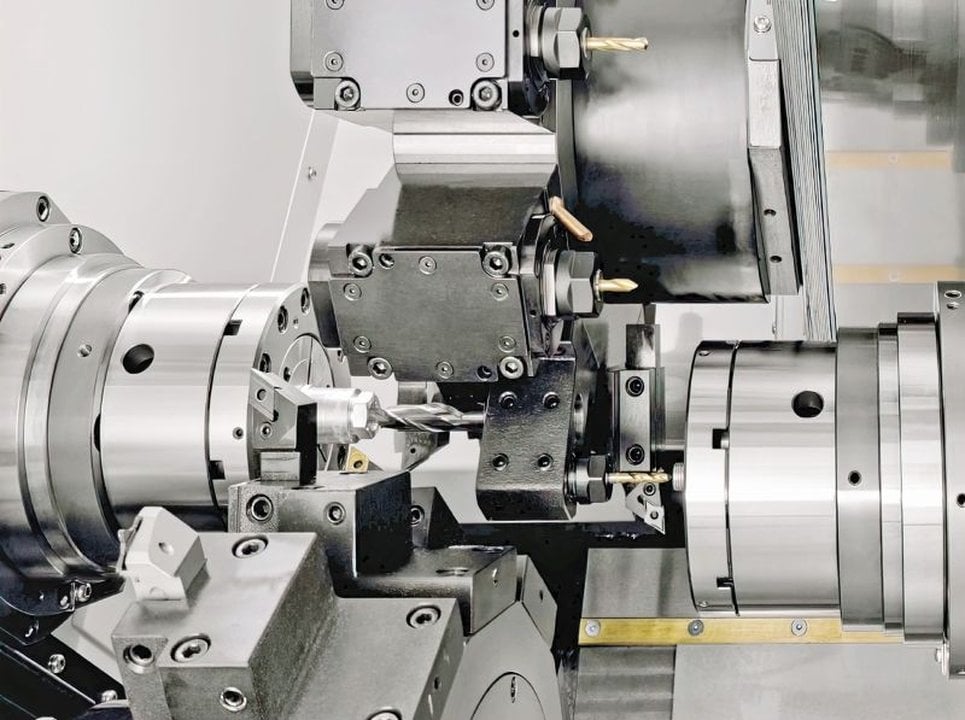

We all know what to expect when we buy a machine tool from Citizen Machinery UK, but one of the considerations is the guidebush.

We visited Colpa Precision in Watford who have gone for the flexibility of a Guidebush / Non-Guidebush A20 sliding head lathe. But what were the reasons?

Having the flexibility to switch between the two means;

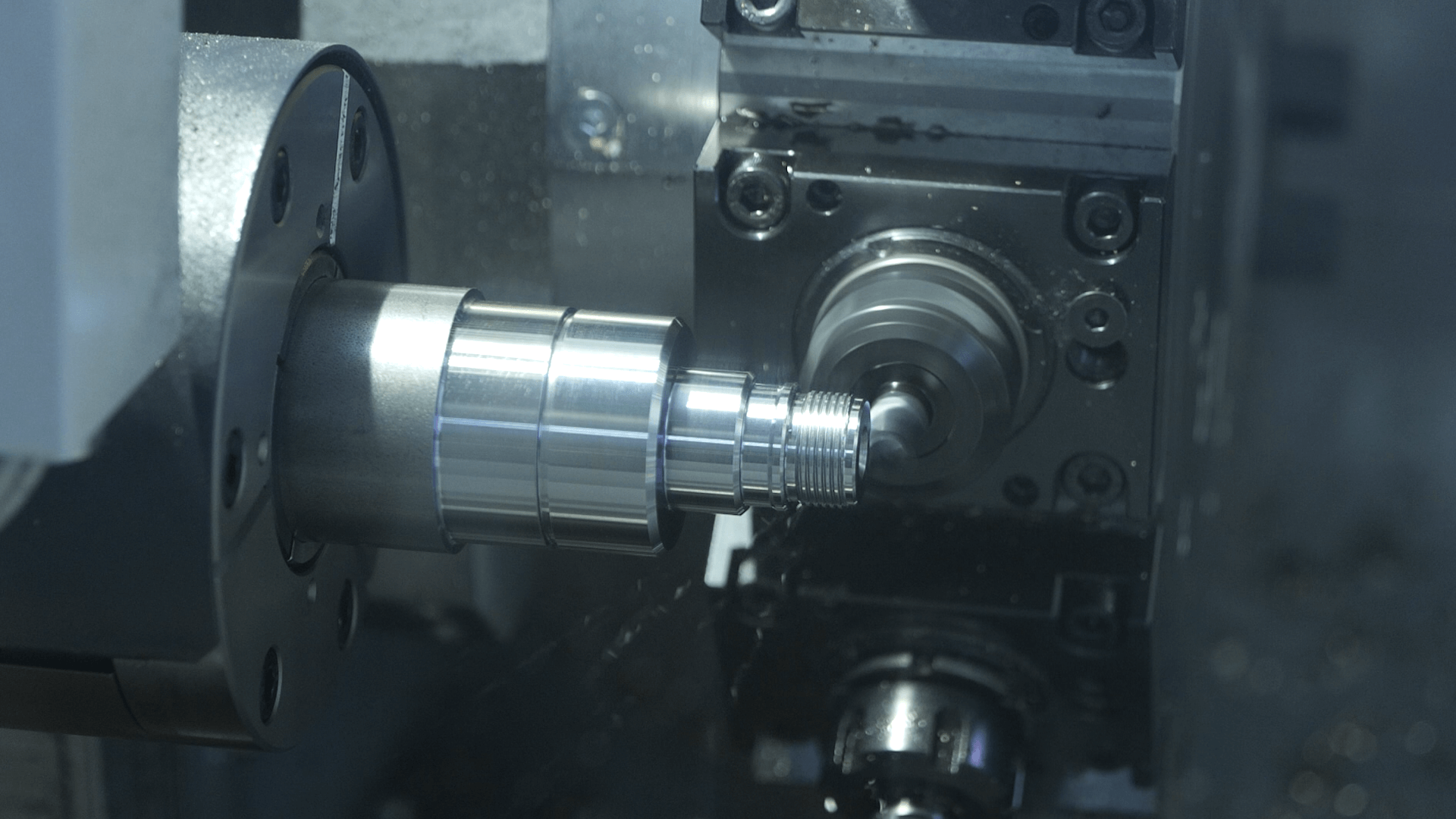

– Less remnant, which can be invaluable when using those expensive materials such as brass.

– No need to grind the bar. Previously they were having to grind the bar, which in itself had a cost, but also a 4 week lead time.

So having a quality machine with that extra flexibility has ensured some great time and cost savings for Colpa Precision. Music to any engineers ears!