Safran Electronics & Defense Improves Air Quality and Energy Efficiency with 3nine

Safran Group’s Safran Electronics & Defense is a world leader in the development of optronic, avionic, and electronic solutions for land, naval, aeronautical, and space applications. At its Montluçon facility in France, the company specializes in manufacturing components for satellites, radars, drones, and other advanced systems used in the aerospace and defense industries.

Ensuring the health and safety of employees is a key priority for Safran Electronics & Defense. As part of its risk prevention strategy, machine tools were originally equipped with electrostatic filters connected to a central ventilation system that vented contaminated air outside the plant to remove oil mist. However, with a workshop volume of approximately 1,700 m³, maintaining a stable indoor temperature became increasingly costly. This prompted the launch of a project to evaluate whether air could be recycled instead of exhausted outdoors.

Early tests showed that the electrostatic filters rapidly lost efficiency when disconnected from the central ventilation system, allowing oil mist to spread throughout the workshop. Maintaining acceptable air quality would have required frequent and impractical maintenance, leading to the climate control project being put on hold.

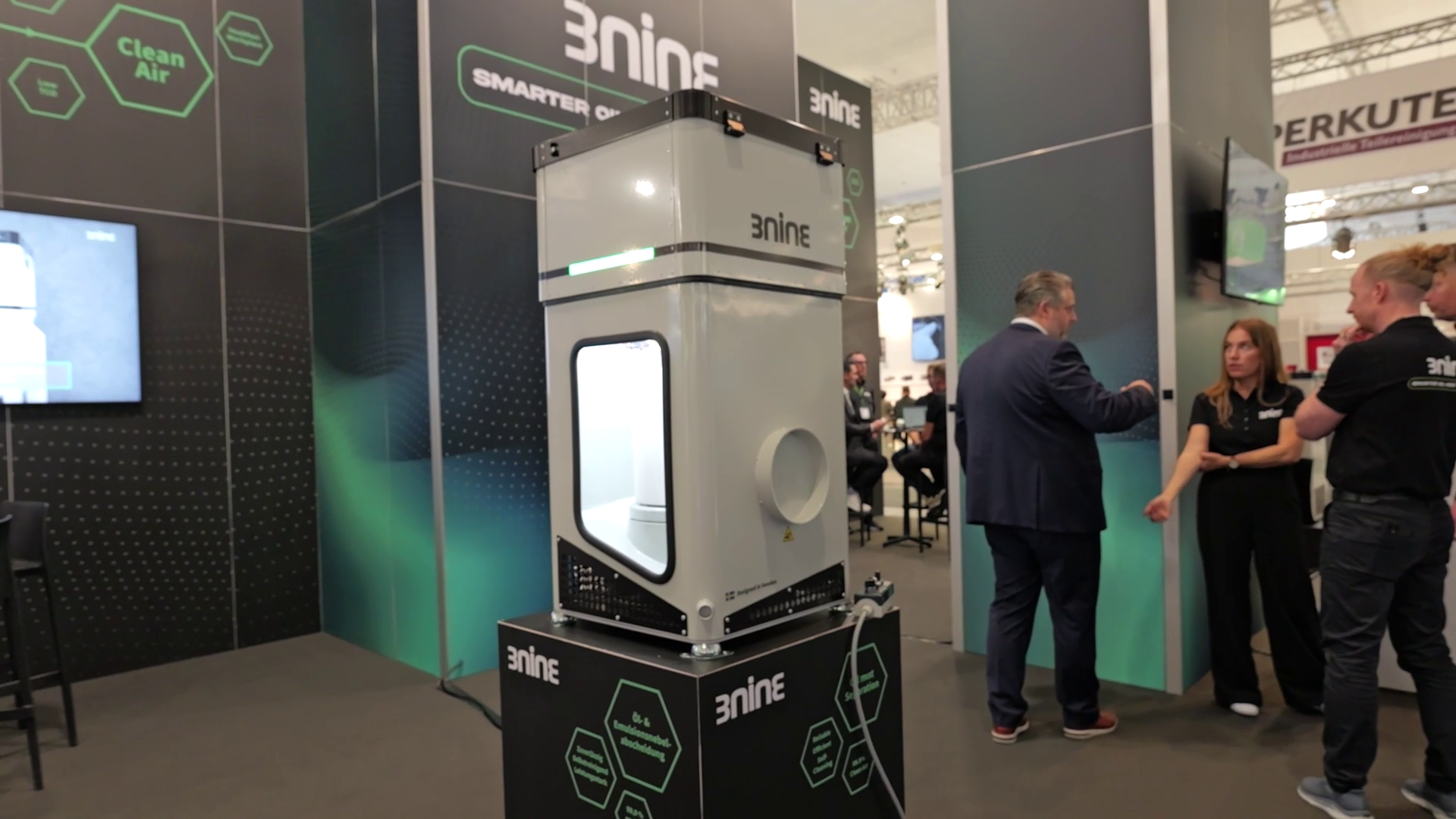

In 2016, Safran Electronics & Defense was introduced to 3nine’s technology when a dealer proposed a 3nine Clara oil mist eliminator in connection with the purchase of an Okuma MBH500 H machining center. The performance of the unit met expectations, leading Safran Electronics & Defense to contact 3nine France directly to discuss wider implementation. In 2017, the company invested in seven additional 3nine oil mist eliminators.

As 3nine technology was gradually deployed, it became clear that the air returned to the workshop was clean and suitable for recirculation. This success revived the climate control project, and Safran Electronics & Defense decided to replace all existing electrostatic filters with 3nine oil mist eliminators.

Later in 2017, 3nine was asked to replace an electrostatic filter with a flow rate of 4,000 m³/h on a Mitsui Seiki HJ80A machining center operating with high-pressure coolant. Despite initial doubts from the service manager, Mr. Dumont—particularly when 3nine proposed a Clara unit rated at 1,000 m³/h—the results confirmed the effectiveness of the separation technology.

Today, the entire workshop in Montluçon is fully equipped with 3nine oil mist eliminators. Safran Electronics & Defense can now safely recycle ambient air within the facility, achieving clean air, improved working conditions, and significant gains in energy efficiency.