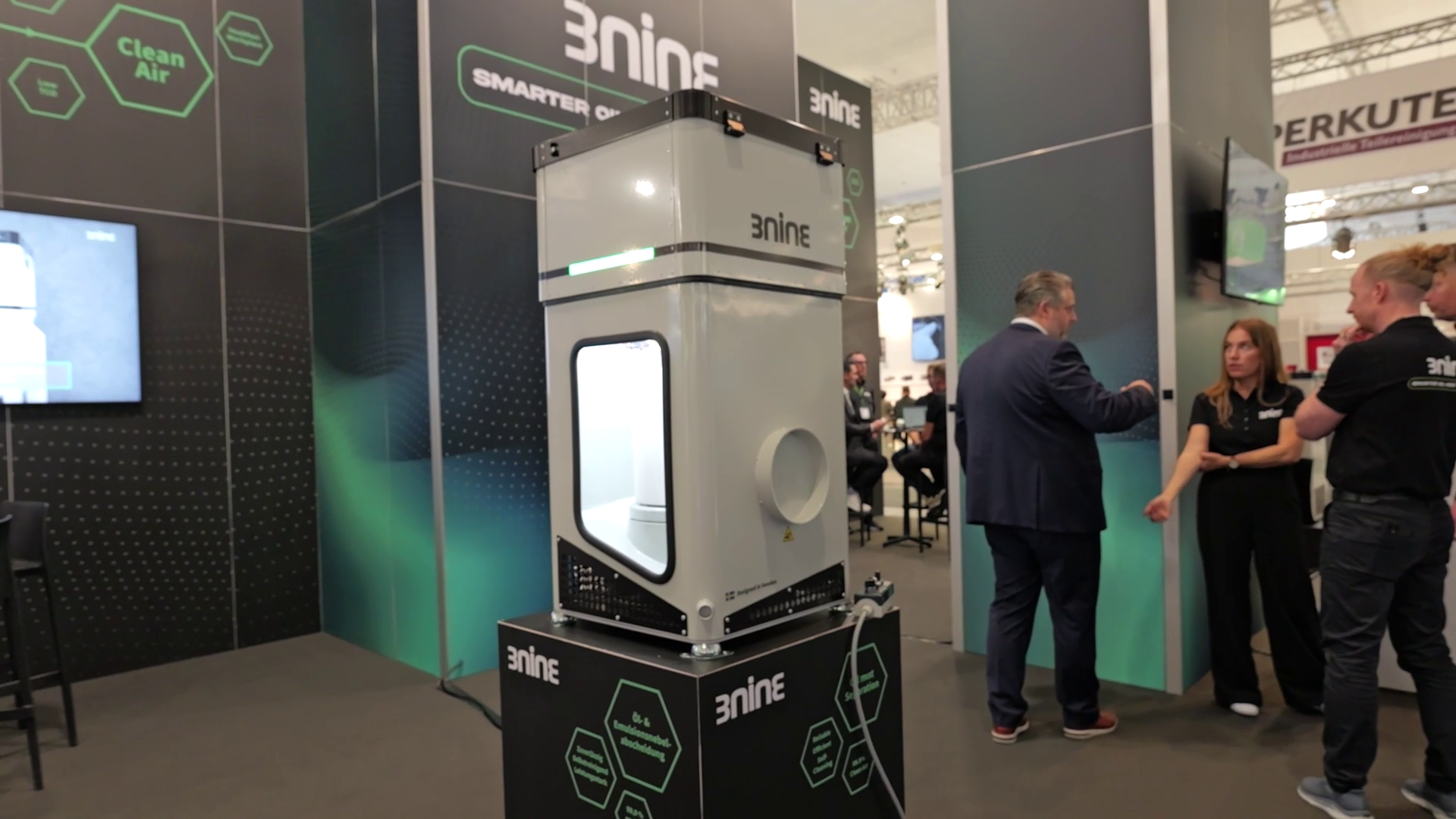

REHOBOT Hydraulics Chooses 3nine to Ensure Clean Air and Safe Production

With more than 100 years of manufacturing expertise, REHOBOT Hydraulics in Eskilstuna, Sweden, is a trusted provider of high-quality hydraulic products for lifting, pressing, and pulling applications. To maintain a clean, safe, and efficient work environment, the company has equipped every machine in its production facility with 3nine oil mist separators.

REHOBOT’s operations are firmly rooted in Swedish manufacturing. All machining, assembly, and testing take place on-site, working with materials such as steel, aluminum, and high-alloy stainless steel. The facility operates 18 Okuma lathes and milling machines, supplied by sister company Stenbergs. To manage the oil mist generated during machining, REHOBOT relies on 3nine units throughout the workshop—from 20-year-old Lina models to newer solutions such as Anna and Nova.

“When we invest in a new machine from Stenbergs, 3nine is our first choice for oil mist separation. We know it works—the machines just do their job,” says Magnus Persson, Production Manager at REHOBOT.

Maintenance of the oil mist separators is handled by service technician Magnus Wilhelmsson from MW Elteknik, who is responsible for all Okuma machines and related equipment. As part of routine service, he checks filters, hoses, and rotor function, but emphasizes that the actual maintenance needs are very limited.

“They’re really solid units. In most cases, there’s hardly anything that needs to be done. Filters last two to three years depending on the process,” says Magnus Wilhelmsson.

He also highlights the practical advantages of the compact design:

“Because the separators are mounted directly on top of the machines, they’re easy to move when we reorganize the layout. There’s no need for ducting or reinstallation.”

By equipping its machines with 3nine oil mist separators, REHOBOT Hydraulics ensures clean air and healthier working conditions, while also reducing environmental impact and achieving a lower total cost of ownership.