Driving Digital Quality – A Behind-the-Scenes Look at Wilcox Industries with 1Factory

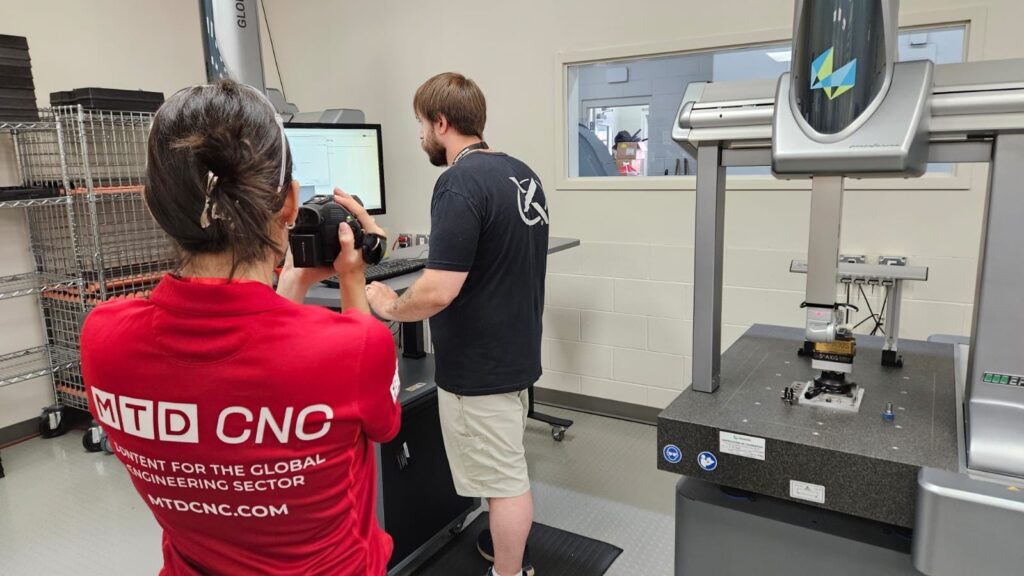

Recording day at Wilcox Industries in New Hampshire – and what an eye-opening experience it was.

Today, Arthur Field and Ana Fernanda Melendez had the incredible opportunity to visit the world-class manufacturing facility of Wilcox Industries, a leader in the design and production of tactical equipment for military and law enforcement professionals.

From cutting-edge helmet-mounted systems to advanced weapon accessories and life-support solutions, Wilcox is at the forefront of engineering innovation in the defence sector. But what really stood out today was not just the high-quality output — it was how they ensure that quality.

Transforming Manufacturing with 1Factory

At the heart of Wilcox’s operational excellence is 1Factory — a powerful software platform designed to streamline quality control and process management across manufacturing lines. The system enables real-time data capture, inspection tracking, and statistical process control, all in one unified solution.

Touring the facility, we saw how 1Factory integrates seamlessly into Wilcox’s workflow, helping engineers and operators stay on top of production tolerances, catch deviations early, and maintain full traceability — all while improving efficiency. The result? Fewer errors, faster response times, and rock-solid compliance.

It’s clear why 1Factory is gaining momentum across advanced manufacturing environments — it gives teams the tools to turn data into action, and quality into a competitive edge.

Over 50 Mazak Machines in Action

Adding to the technological muscle of the operation, Wilcox Industries runs a fleet of more than 50 Mazak North America machines — a testament to their commitment to precision, productivity, and reliability. From multi-axis turning centres to high-speed milling platforms, Mazak equipment is the backbone of this facility’s machining capabilities, delivering consistent performance across a wide range of complex components.

Seeing this combination of advanced machinery and smart software in action offered a glimpse into the future of connected manufacturing — where automation, analytics, and operator expertise work hand in hand.

Huge thanks to the Wilcox team for opening their doors and giving us an inside look at what modern, high-stakes manufacturing truly looks like. From defence-grade product innovation to next-gen quality control, this was a day full of insight, inspiration, and impressive technology.

🎥 Stay tuned — full video coverage coming soon on MTDCNC!