We are proud to be designated as Main Dealer Europe for Toshiba Machine of Japan who, as a recognised world leader in the machine tool industry, uses the latest technology to meet the needs of all major industries. The range of CNC machine tools includes machining centres, boring machines, gantry mills and 5-axis machines. Toshiba Machine manufacturers almost everything from start to finish – castings from their own foundry and their own control systems ensure total machine integrity and compatibility.

There are currently two ranges of horizontal machining centres available, BMC and BM, and they’re perfect for manufacturing components within the aerospace, power generation, automotive, marine, construction and transportation industries.

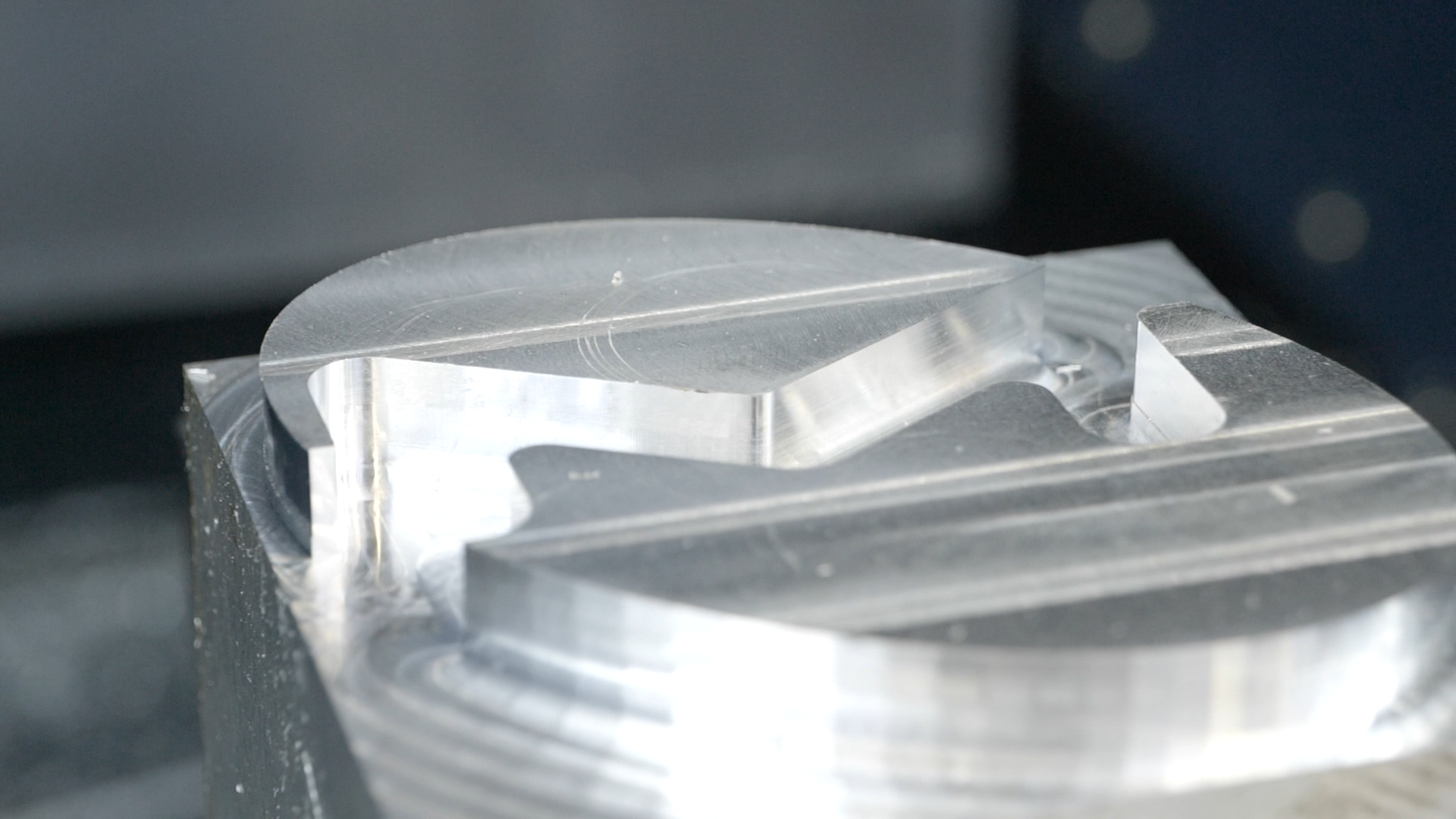

The BMC Series of large horizontal machining centres has been designed for maximum metal removal. The machines use a shuttle-type pallet changer in order to accommodate large heavy workpieces and, when fitted with linear scales, achieve an accuracy of ±0.002 mm over the full axis strokes. A full five axis BMC machine is available using a trunnion type table for complex workpieces.

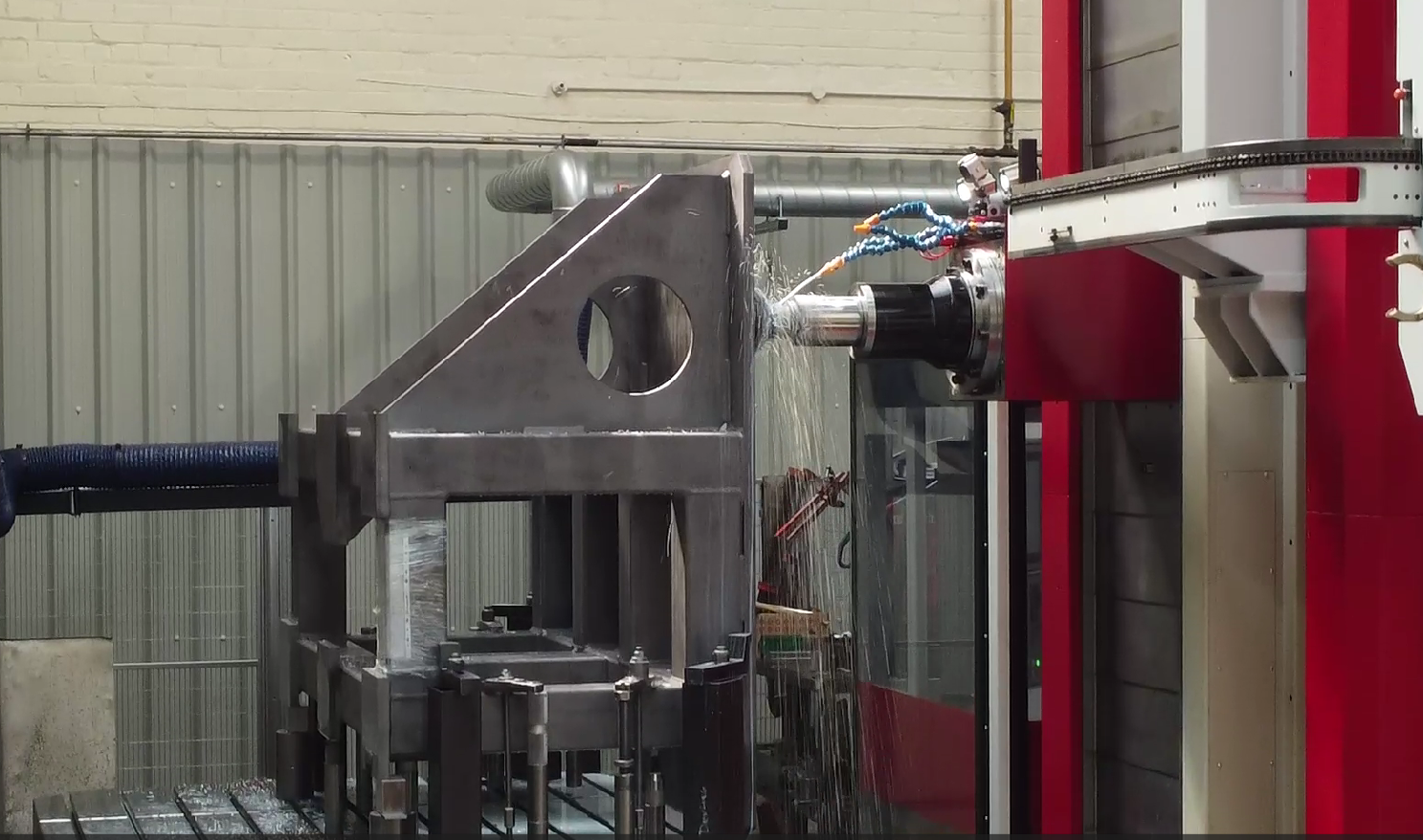

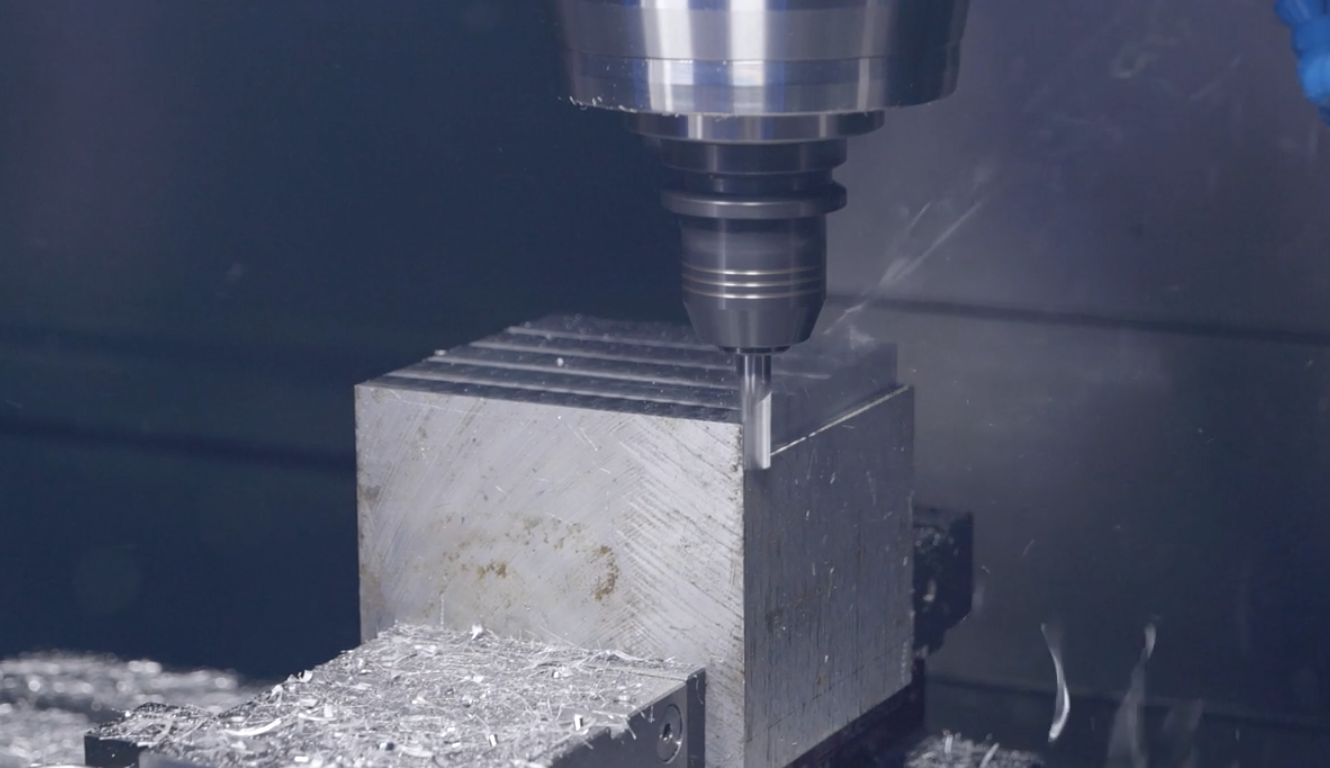

The BM Series consists of the BM-Q, BM-U and BM-H all offering variations of features and advantages. The BM-Q model is fitted with a Ø200mm W axis quill for improved reach and has a BBT50 face/taper contact spindle running at 6000rpm, developing 1600N.m of torque using a 30kW motor. The spindle is cooled using a chiller unit and a high-power spindle is available for heavier cutting. The BM-U model is fitted with a rotary A axis head with a spindle speed of 12000rpm, driven by a 64kW motor developing 236N.m of torque. The head indexes at ±95º from the horizontal plane presenting an angular approach to workpieces for compound work and providing improved tool clearance. The BM-H high speed model is fitted with an HSK63A spindle running at a speed of up to 20000rpm. The spindle is driven by a 51kW motor developing 89N.m of torque. The 35000kg machine mass is indicative of its robust and rigid structure and, as a result of careful structural design based on overt 40 years of experience on building machining centres, Toshiba have kept the BM-Q size down to 5.5M wide and 8M deep resulting in a low 800kg/M² floor loading.