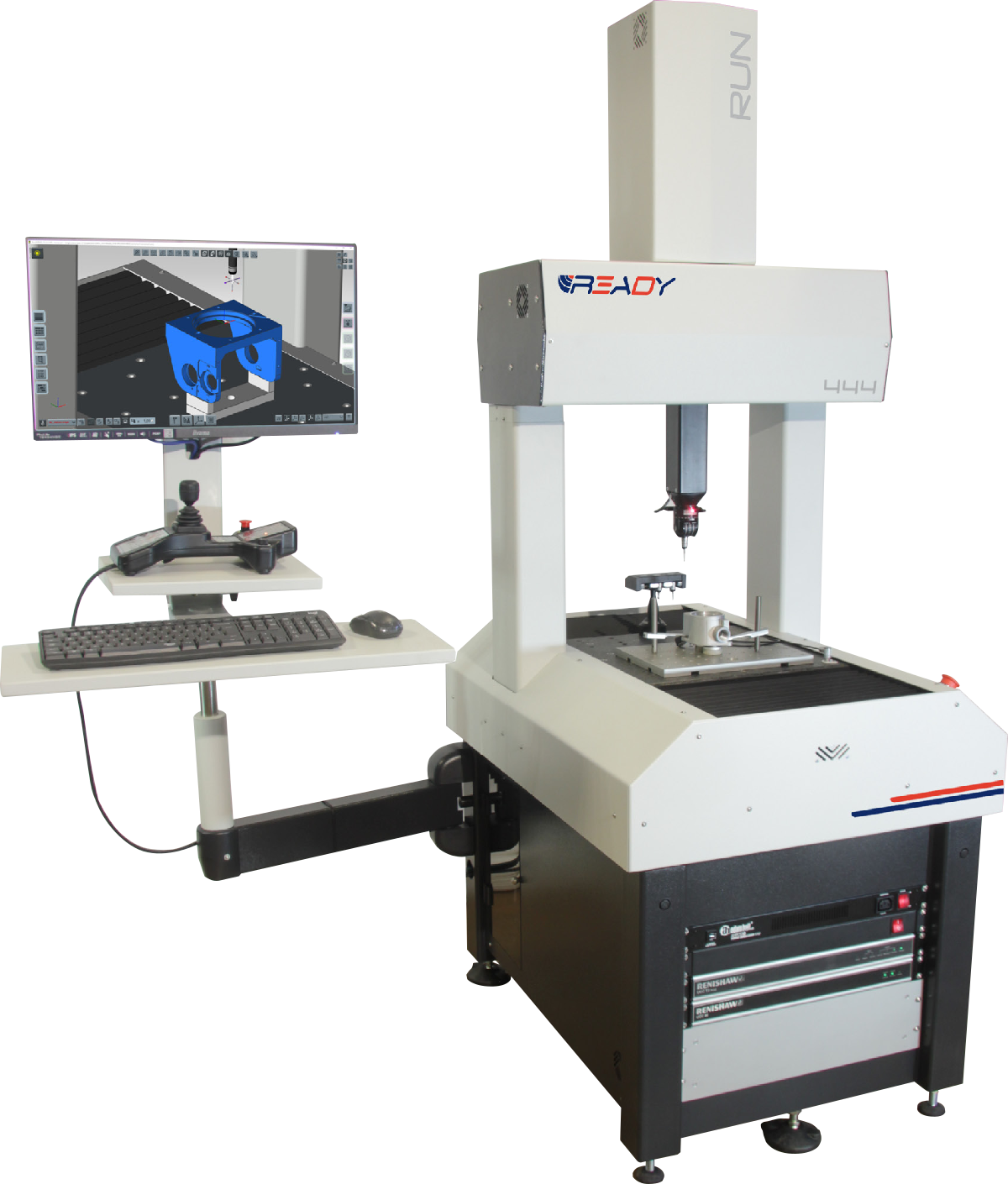

Ready Metrology Launches Run CMM Line for Fast, Shopfloor-Ready Inspection!

Ready Metrology has introduced its Run line of coordinate measuring machines (CMMs), engineered to deliver metrology-grade precision directly on the shopfloor. Designed to provide immediate measurement data, the Run systems aim to help manufacturers prevent process deviations, reduce scrap rates and shorten setup times across production environments.

The Run lineup combines robustness, accuracy and user-friendly operation to support fast inspection, real-time feedback and tighter process control at every stage of manufacturing. These CMM systems are designed to integrate seamlessly into production workflows, transforming inspection from a post-process verification step into an active component of manufacturing performance.

A key feature of the Run systems is the use of linear motor technology, which enables maintenance-free operation. By eliminating the need for air supply and lubrication, the machines ensure long-term reliability even in challenging shopfloor conditions. This design reduces downtime and simplifies maintenance requirements.

The Easy Runner interface allows operators to load and execute inspection programs with a single touch. A moving table structure, combined with an optional clamping kit, enables quick and ergonomic part handling. Switching between part programs is streamlined through barcode scanning, which automatically loads the appropriate measurement routine and generates reporting with minimal operator input.

The moving table configuration also facilitates robotic integration. Since both the portal and measuring head remain outside the moving range, safety during setup is enhanced and part loading times are reduced. This architecture supports automated inspection cells and high-throughput production environments.

To ensure consistent accuracy, the Run systems incorporate advanced performance features such as an automatic stylus cleaning unit and an active anti-vibration granite base equipped with pneumatic dampers. These elements maintain stable and repeatable measurement performance even under variable shopfloor conditions.

The machines support both end-of-line inspection and in-process verification. Integrated CAD import capabilities and geometric dimensioning and tolerancing (GD&T) analysis provide detailed insights into part geometry, helping manufacturers ensure compliance with specifications while accelerating process improvement initiatives.

With the Run CMM line, Ready Metrology positions measurement as a real-time production resource. By delivering fast, actionable data directly on the shopfloor, the system is designed to enhance productivity, improve quality control and strengthen overall manufacturing efficiency.