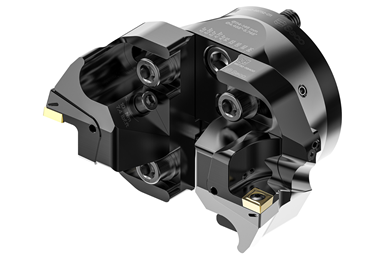

Seco BB732 Boring Bridges Enhance Stability and Surface Finish in Deep-Hole Machining!

Seco has introduced the BB732 boring bridge, a modular solution engineered to optimize deep-hole boring operations when used with Steadyline bars. Designed for both roughing and finishing applications, the BB732 bridges are built to deliver vibration-free performance, improved coolant flow and high-quality surface finishes in demanding machining environments.

The BB732 bridges are specifically tailored for use with the Steadyline SM40 shell-mill toolholder, supporting roughing diameters from 114 mm to 301 mm and finishing diameters up to 315 mm. The toolholder’s conical-reinforced design enhances static and dynamic rigidity, reportedly providing up to three times greater stiffness compared to conventional solid toolholders. This rigidity, combined with the integrated Steadyline vibration damping system, enables stable and precise machining even in deep-bore scenarios where deflection and chatter are common challenges.

A key benefit of the BB732 system is its ability to handle both roughing and finishing tasks without requiring separate tooling setups. This dual capability reduces tool inventory requirements and shortens setup times, improving operational efficiency on the shop floor. The modular configuration also allows manufacturers to adapt the system to various deep-hole machining requirements with minimal complexity.

Coolant management is a central feature of the BB732 design. The system directs coolant precisely to the cutting edge, promoting efficient chip breaking and helping maintain lower insert temperatures. Optimized coolant delivery enhances process stability, extends insert life and contributes to improved surface finish quality.

Operator safety has also been addressed through the inclusion of a built-in safety stopper designed to prevent block ejection caused by centrifugal forces during rotation. This feature enhances reliability and reduces risk in high-speed, large-diameter boring operations.

According to Seco’s product management team, the BB732 bridges are designed to integrate seamlessly with Steadyline bars, particularly the SM40 series, offering a stable and efficient solution for deep-hole machining with larger-diameter tools.

With the BB732 boring bridge, Seco expands its deep-hole machining portfolio, providing manufacturers with a vibration-controlled, coolant-optimized system aimed at improving productivity, surface finish quality and operational safety.