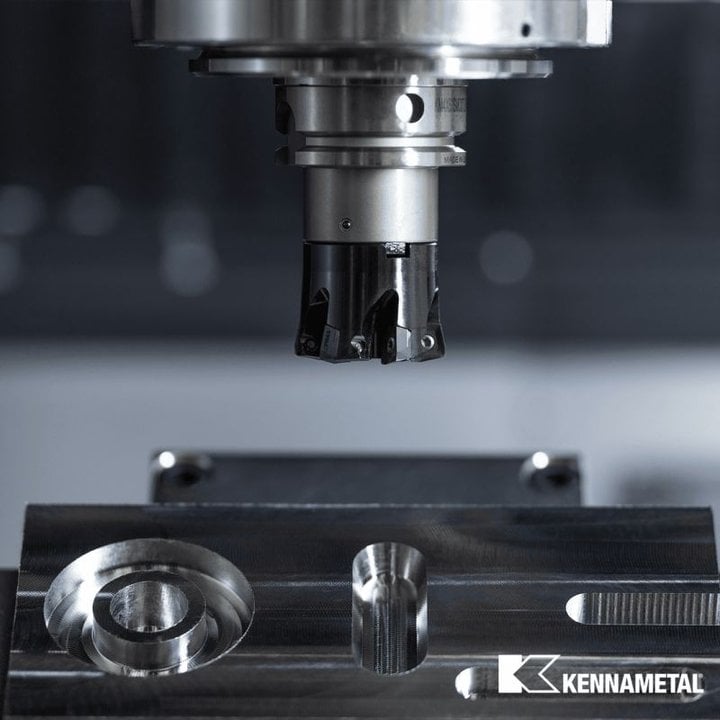

Kennametal has introduced its latest innovation, the 7792VX High Feed Indexable Milling Platform, designed to elevate productivity in challenging manufacturing environments. This new platform is tailored to enhance performance when machining aerospace alloys, stainless steel, and high-temperature materials.

Engineered for maximum metal removal, the 7792VX platform achieves superior surface finishes while maintaining rock-solid stability. This allows manufacturers to confidently handle tougher materials, optimizing their high-feed milling processes.

Kennametal’s product addresses the growing demand for precision and efficiency in the manufacturing sector. By improving tool life and productivity, the 7792VX platform offers a substantial advantage to manufacturers aiming to reduce downtime and operational costs. Its high-feed capability is particularly well-suited for industries requiring robust performance and reliability, such as aerospace and automotive manufacturing.

As a leader in metal cutting and tooling solutions, Kennametal continues to push the boundaries of what is possible in the manufacturing world. This latest offering underscores the company’s commitment to innovation and its role in driving industrial efficiency and productivity.

Manufacturers interested in taking their operations to the next level may find the 7792VX High Feed Indexable Milling Platform to be an invaluable asset in meeting their production goals. Kennametal’s dedication to cutting-edge technology and excellence remains unwavering as it continues to address the needs of the global manufacturing industry.

View more news from Kennametal