Sodick Europe Highlights Ultra-Precision Manufacturing at SABATO GROUP in Switzerland

Switzerland — Sodick Europe recently supported a technical visit to SABATO GROUP, located in the heart of Switzerland’s famed Watch Valley, offering insight into the extreme precision required to manufacture components for the luxury horology industry.

Specialising in prototyping, tooling and the production of high-precision watch components, SABATO GROUP operates in an environment where tolerances are measured in microns. Their standard manufacturing capability of ±2 microns ensures that intricate watch mechanisms — often made up of hundreds of miniature parts — function reliably over long periods of time.

In mechanical watchmaking, even the smallest variation can affect performance. Maintaining consistent dimensional accuracy at this level requires a combination of skilled engineering, stable processes and reliable machine technology.

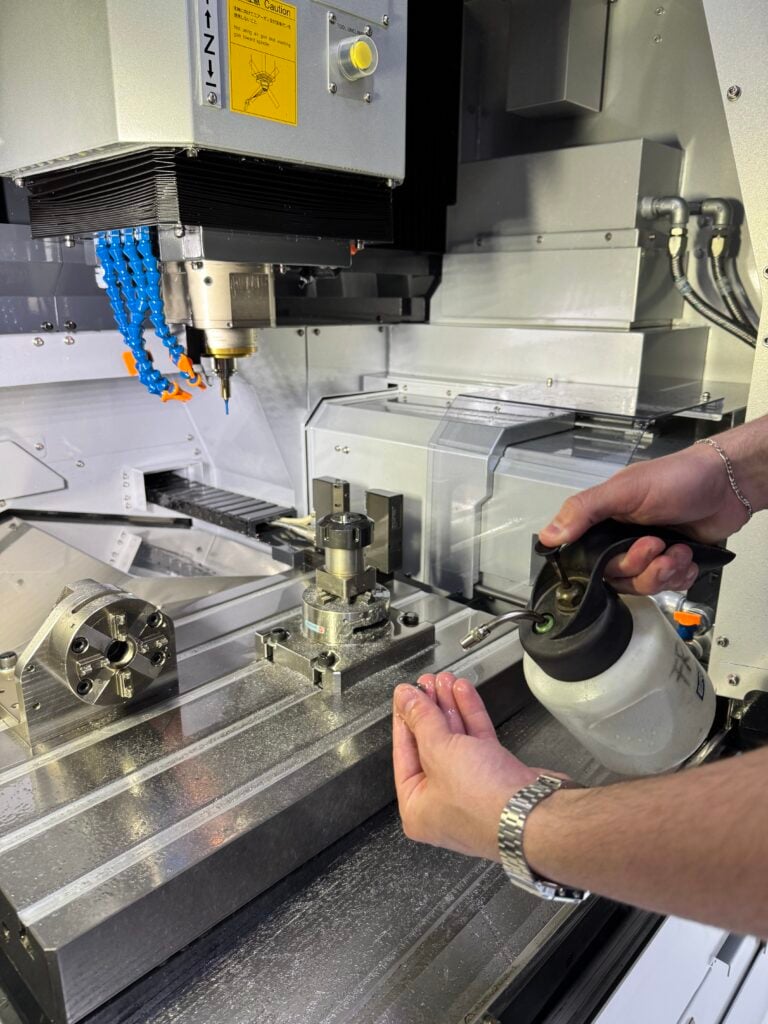

During the visit, the production team demonstrated a comprehensive machining setup that includes Sodick milling machines alongside die-sinking and wire EDM technology. A notable observation was the continued performance of older-generation equipment running alongside the latest models, with both consistently achieving demanding tolerance targets.

This balance of innovation and long-term machine stability highlights the importance of precision-focused manufacturing strategies within the watchmaking sector.

Sodick Europe, together with Celada Suisse SA, continues to work closely with partners across Europe to support manufacturers operating at the highest levels of accuracy and quality.