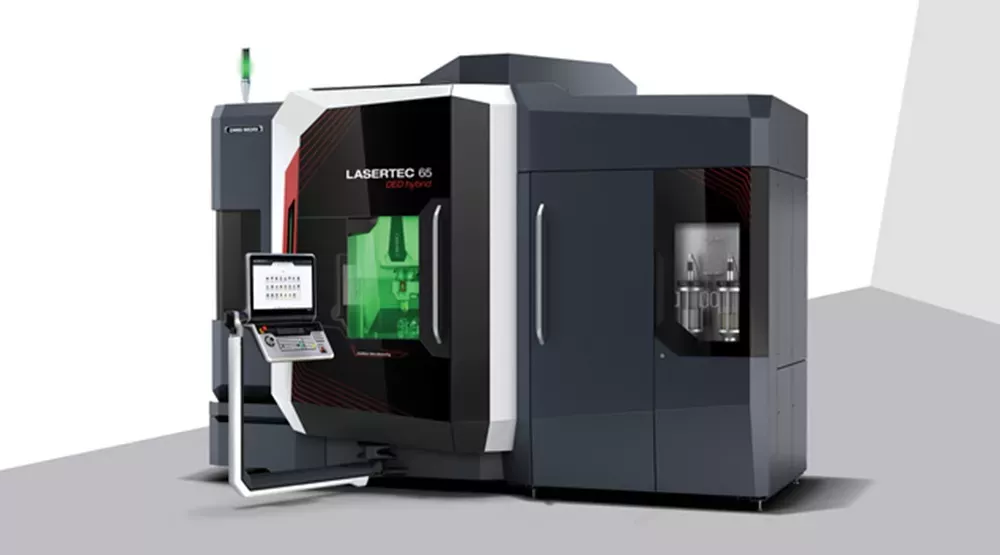

DMG MORI LASERTEC 65 DED Hybrid 2nd Generation Expands Multi-Process Additive Manufacturing Capabilities!

DMG MORI has introduced the LASERTEC 65 DED hybrid 2nd Generation, a next-generation additive manufacturing platform that integrates laser deposition welding with five-axis simultaneous milling in a single setup. Designed to advance multi-process manufacturing, the system brings together additive and subtractive technologies within one machine environment to streamline complex part production.

The LASERTEC 65 DED hybrid combines six processes in a single workspace: milling, turning, grinding, preheating, additive manufacturing via a powder nozzle and 3D scanning. This consolidation enables manufacturers to complete multiple stages of part production without repositioning the workpiece, improving accuracy and reducing setup time.

A newly developed MultiJet nozzle supports five-axis material deposition with uniform powder distribution. According to the company, this innovation increases build-up rates by 35 percent while reducing part costs by 47 percent. The expanded working area accommodates components measuring up to 840 mm by 350 mm or 680 mm by 400 mm, enabling workpieces up to 170 percent larger than the previous generation. The increased build volume also reduces volume-related costs by more than 70 percent.

Material versatility is enhanced through the integration of both infrared and blue laser technology. This dual-laser capability allows processing of highly reflective materials such as copper and supports graded material transitions and multi-material components. Manufacturers can tailor part properties to specific applications, achieving improved thermal performance, selective hardness exceeding 60 HRC and extended tool life without requiring additional heat treatment.

To ensure process reliability and traceability, the machine incorporates advanced monitoring systems equipped with cameras and sensors. These systems track temperature, powder mass flow, melt pool energy and working distance in real time. The closed-loop control of critical parameters enhances process stability, while digital visualization and documentation of all process data in a three-dimensional, time-based format supports quality assurance and compliance requirements.

The redesigned powder management system emphasizes safe and efficient material handling. Features include sealed argon containers, automatic extraction of fine particles and optional pressure and level monitoring. The machine’s monoBLOCK construction delivers positioning accuracy of 4 microns along with improved volumetric accuracy, contributing to consistent part quality.

Ergonomic operation and automation readiness are supported by wide access doors and a layout designed for integration into automated production environments. Operation and programming are handled through the CELOS X control platform with Siemens SINUMERIK ONE and proprietary technology cycles, providing users with advanced control capabilities and streamlined workflow management.

With the LASERTEC 65 DED hybrid 2nd Generation, DMG MORI continues to expand the boundaries of hybrid manufacturing by combining additive and subtractive processes into a unified, high-precision production platform.