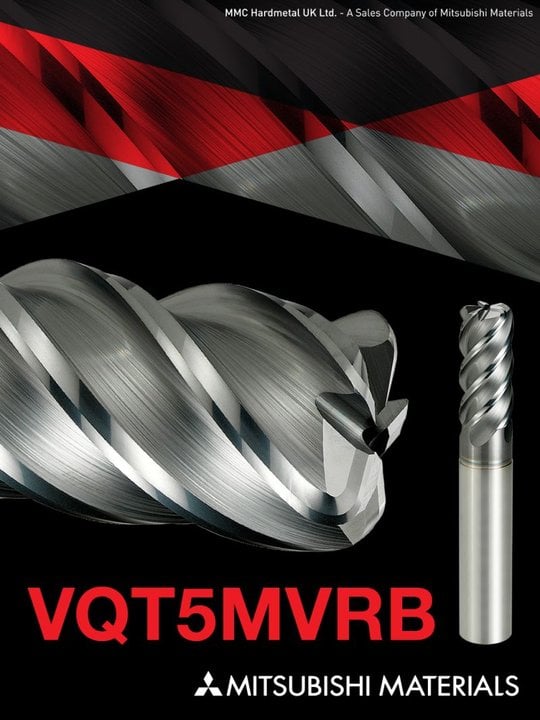

Mitsubishi Materials has introduced a new line of high-performance tools, the VQT Series, specifically designed to enhance efficiency in titanium machining. This innovative series includes the VQT5MVRB Corner Radius End Mill, setting a new standard for machining excellence.

The VQT5MVRB features a unique 5-flute design, which significantly boosts machining efficiency. Its distinctive rake angle and through-coolant capability make it ideal for high-efficiency deep slot milling. This advancement facilitates smoother operations and superior finishes, even in demanding titanium machining processes.

Central to this innovation is Mitsubishi’s Smart Miracle technology. By integrating this cutting-edge technology, the VQT Series promises to improve machining performance, increasing both tool life and cutting precision. This development is poised to significantly impact various sectors that rely heavily on titanium components, such as aerospace and automotive industries.

With the introduction of the VQT Series, Mitsubishi Materials continues to demonstrate its commitment to pioneering solutions that drive manufacturing forward. As industries worldwide seek to optimize their machining processes, the VQT Series stands out as a key player in meeting these evolving demands.

Mitsubishi Materials, a leader in cutting tool technology, consistently delivers high-quality solutions that cater to the manufacturing industry’s needs. Their ongoing focus on innovation and performance underscores their position as an influential force in the global manufacturing sector.

View more news from MMC Hardmetal UK Ltd