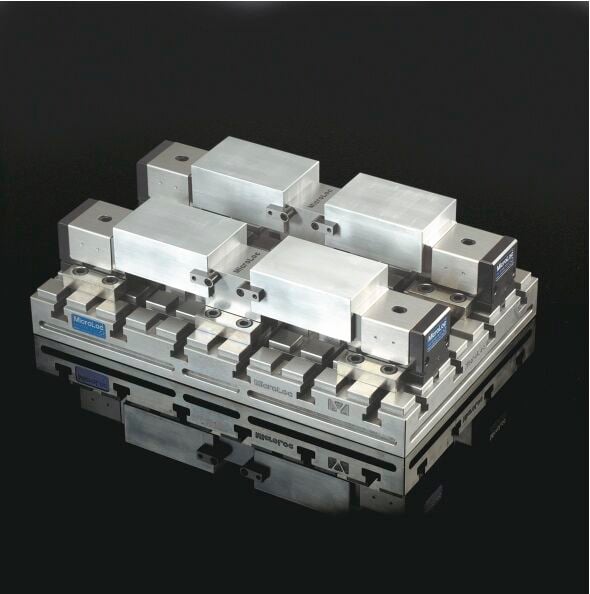

A new EasyLock Zero Point System from MicroLoc is now going through final testing ahead of dispatch — and it’s a great example of how smart workholding can transform productivity on the shop floor.

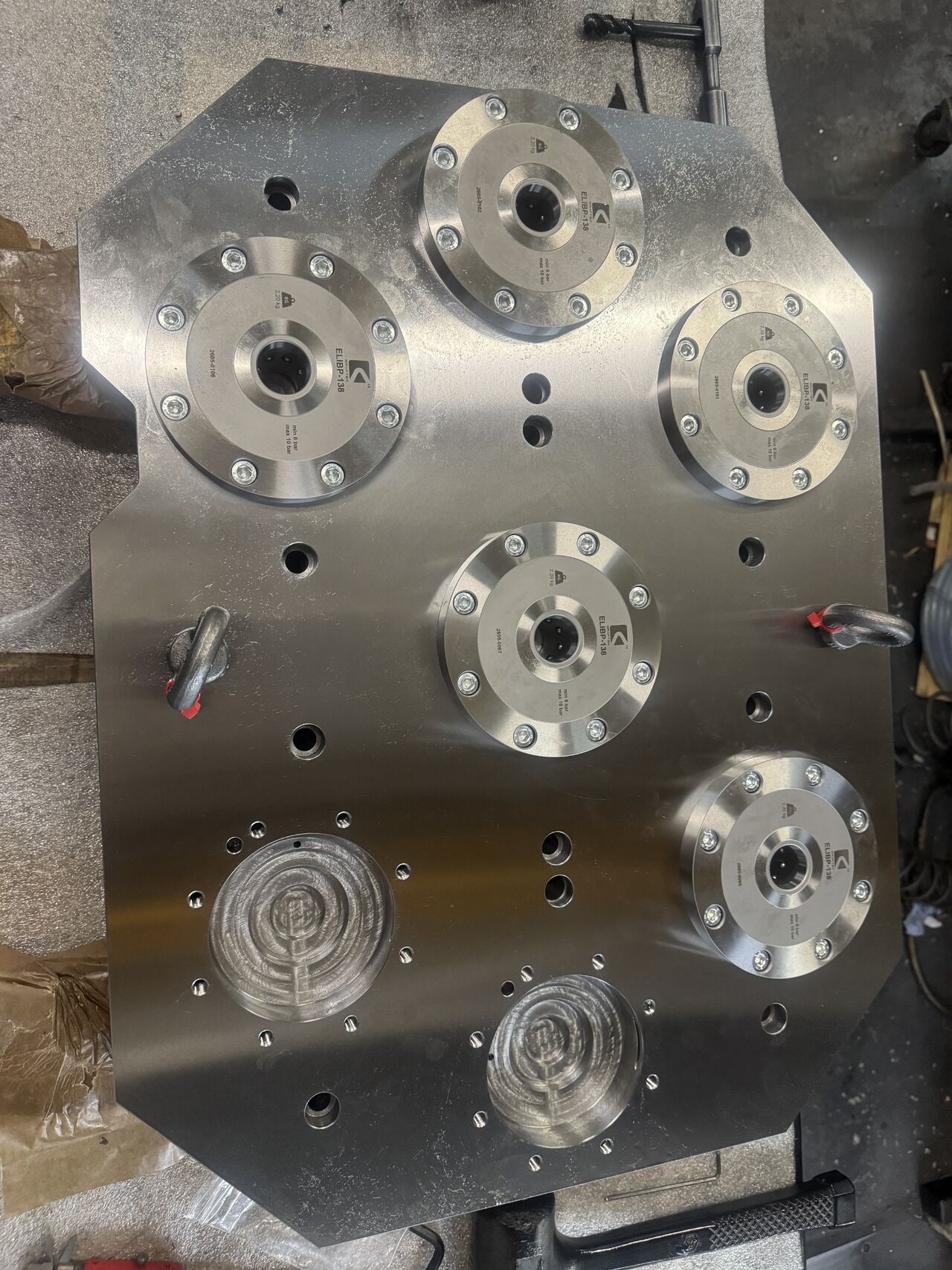

This particular system features a 650 × 500 mm precision plate with seven Zero Point Cylinders machined directly into it. Designed for high rigidity and repeatability, the system is being installed on a Haas EC-1600, making it ideal for large parts and demanding machining operations.

Why Zero Point Systems Make Such a Difference

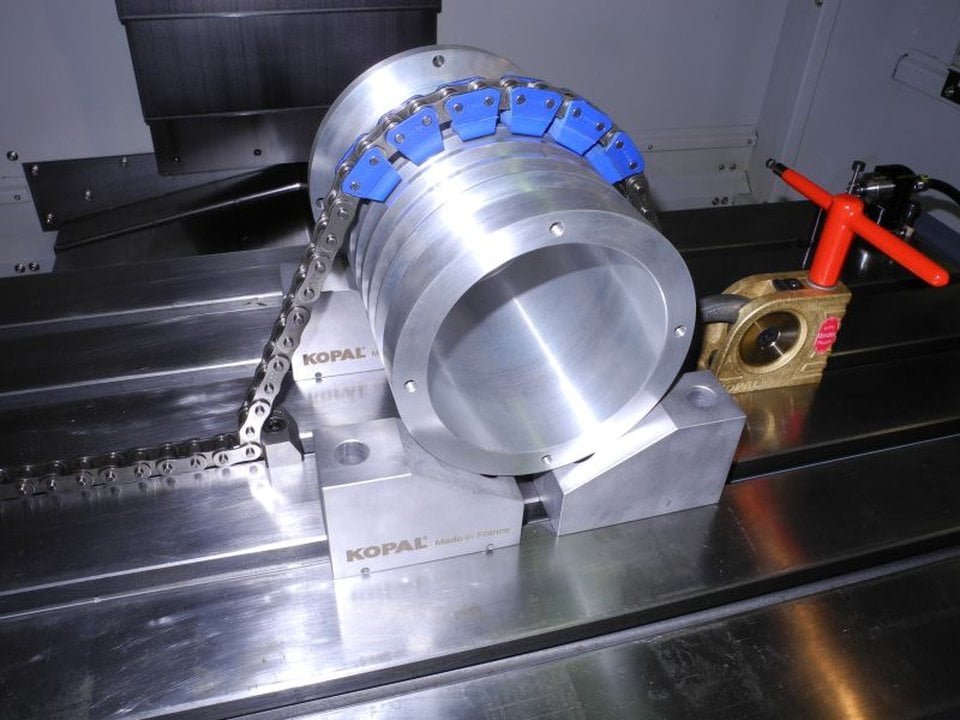

Zero Point clamping is all about eliminating wasted time. Many manufacturers still spend close to one hour per day changing setups on a machine — time when the spindle simply isn’t cutting.

By moving setup work offline and using a Zero Point system, that changeover time can be reduced to just a few minutes.

To put that into perspective:

- 1 hour saved per day

- £65 per hour machine rate

- £16,900 saved per year on a single machine, running one 8-hour shift

Multiply that across multiple shifts or several machines, and the return on investment becomes very clear, very quickly.

Learn More: Technical Insight from MTDCNC

If you’d like a deeper technical understanding of how MicroLoc systems work, take a look at the Technical Corner filmed by MTDCNC, where Paul Jones is joined by Matt Jenness to explore the engineering, accuracy, and practical benefits behind Zero Point clamping.

Installation Story Coming Soon

This EasyLock system installation will also be featured in an upcoming MTDCNC installation story, showing the solution in action and how it’s being applied in a real manufacturing environment.

If reducing setup times, improving repeatability, and unlocking machine capacity are priorities for your business, this is one solution well worth a closer look.