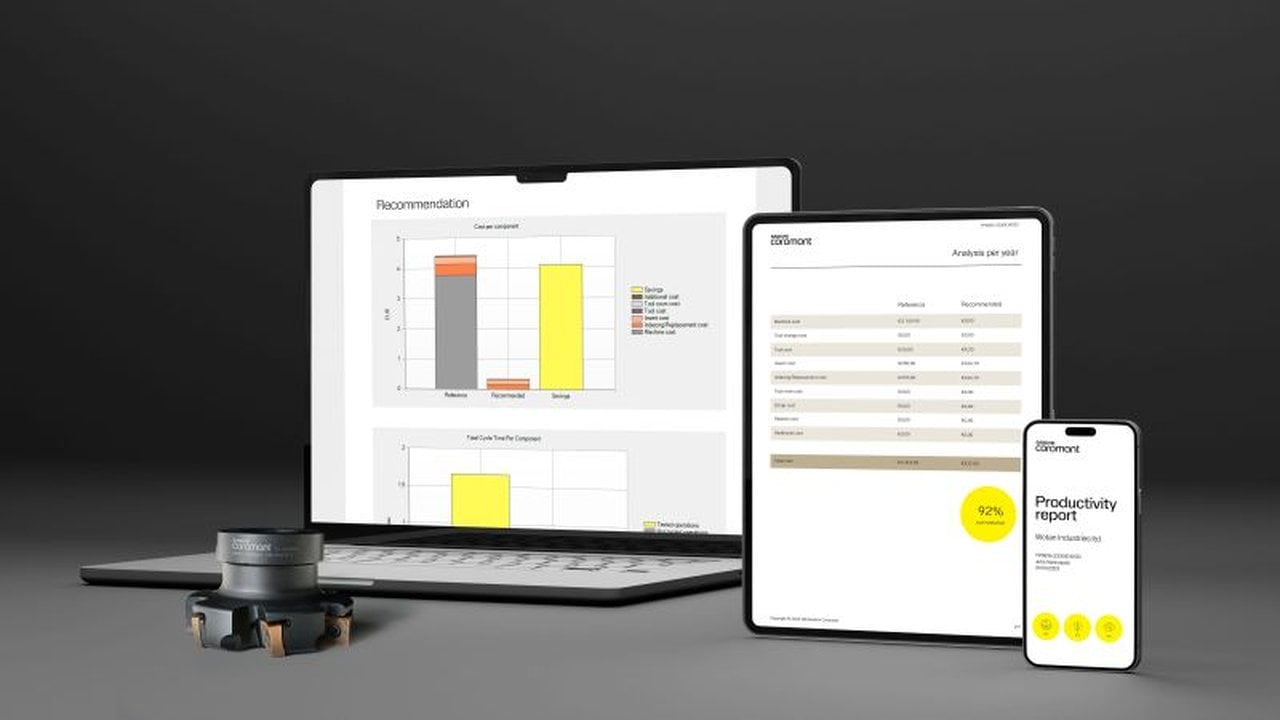

A newly introduced tool is transforming how manufacturers measure and manage energy consumption at the machining level, revealing opportunities for substantial cost savings and productivity gains. In a recent study involving 49 customers, those using the Sustainability Analyzer identified cost-saving opportunities exceeding 30%, while also enhancing productivity.

The increasing energy demands of modern machining, coupled with the need to cut costs and reduce CO₂ emissions, pose significant challenges for manufacturers. Current data shows that only 20-25% of a machine’s energy is used to drive the spindle, while the rest is lost to idle time and inefficiencies. This tool provides visibility into these inefficiencies, enabling manufacturers to optimize energy use.

Developed from the Productivity Analyzer, the Sustainability Analyzer allows manufacturers to connect machining decisions directly to energy consumption and CO₂ impact. This offers a measurable way to enhance efficiency and sustainability.

The company plans to share more detailed findings in the near future. Manufacturers interested in integrating sustainability with profitability are encouraged to explore the Sustainability Analyzer. Further insights can be found in their white paper, available for download.

Sandvik Coromant, a leading name in tooling solutions and innovation within the manufacturing sector, is behind this initiative. The company continues to drive change in the industry by supporting sustainable and efficient manufacturing practices.

View more news from Sandvik Coromant