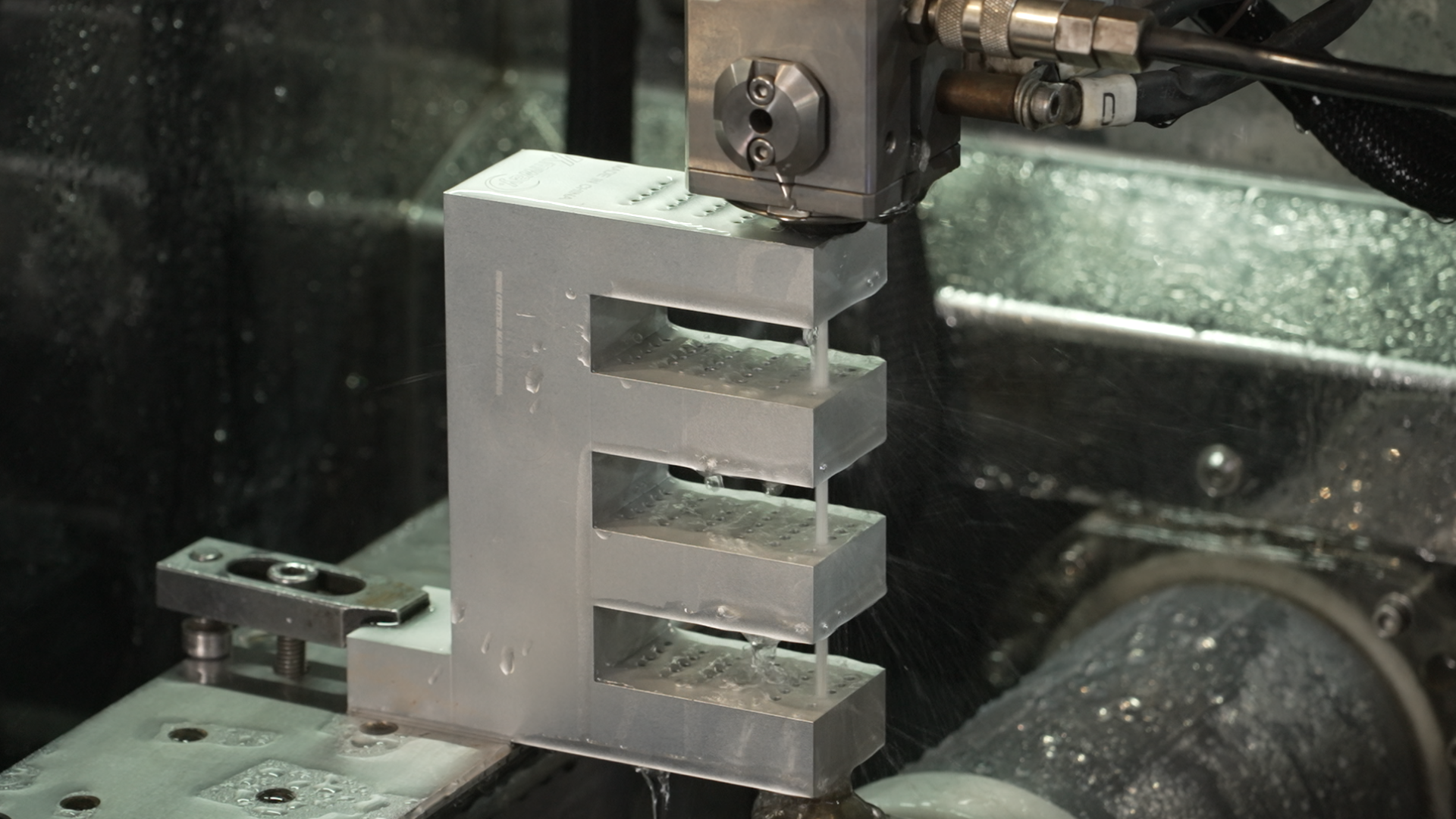

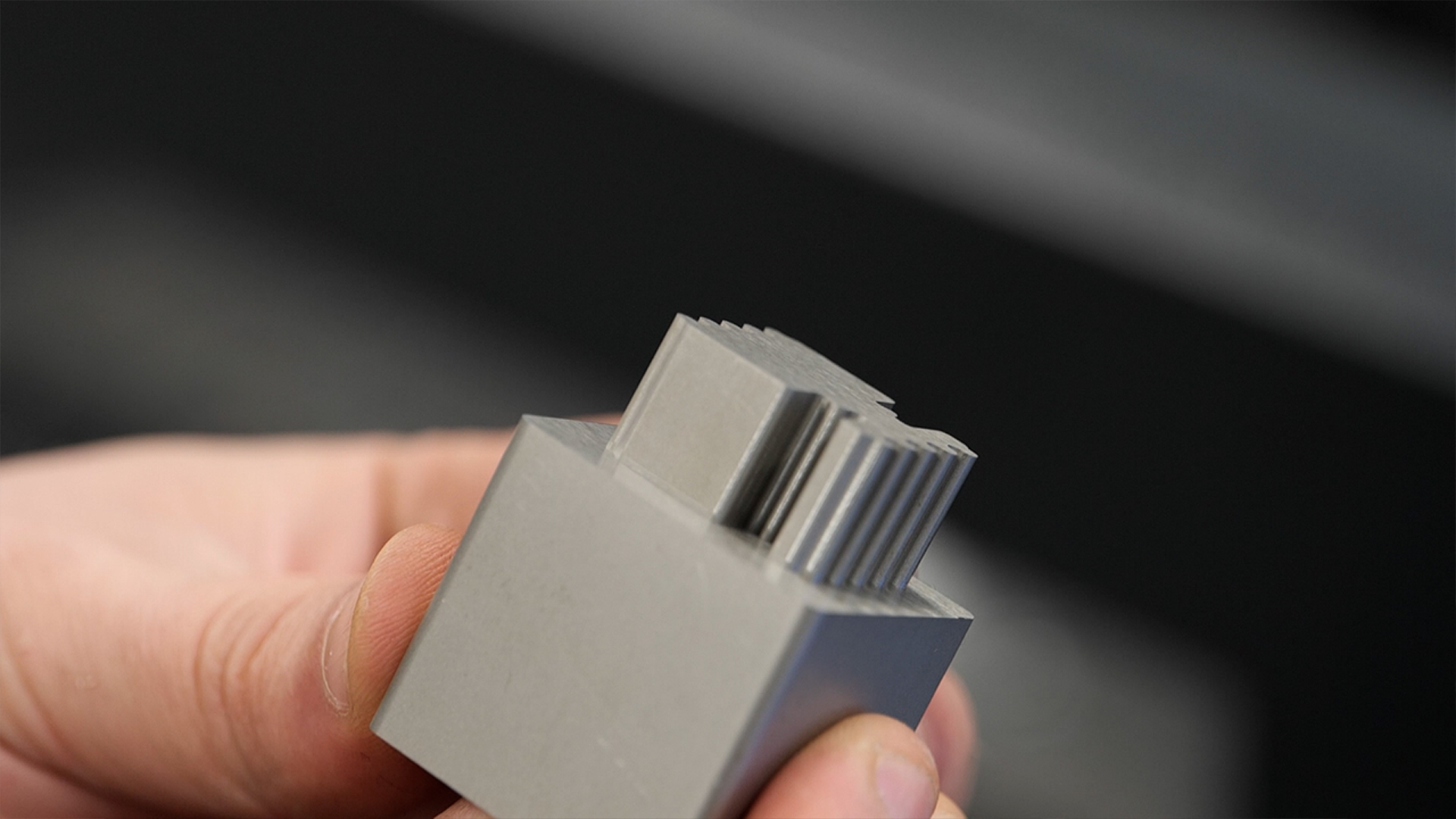

Eurospark Ltd has announced the successful installation of a new Kmway EK Series Wire EDM at a customer’s site. The machine, known for its precision and efficiency, is already delivering impressive results, completing its first batch of parts.

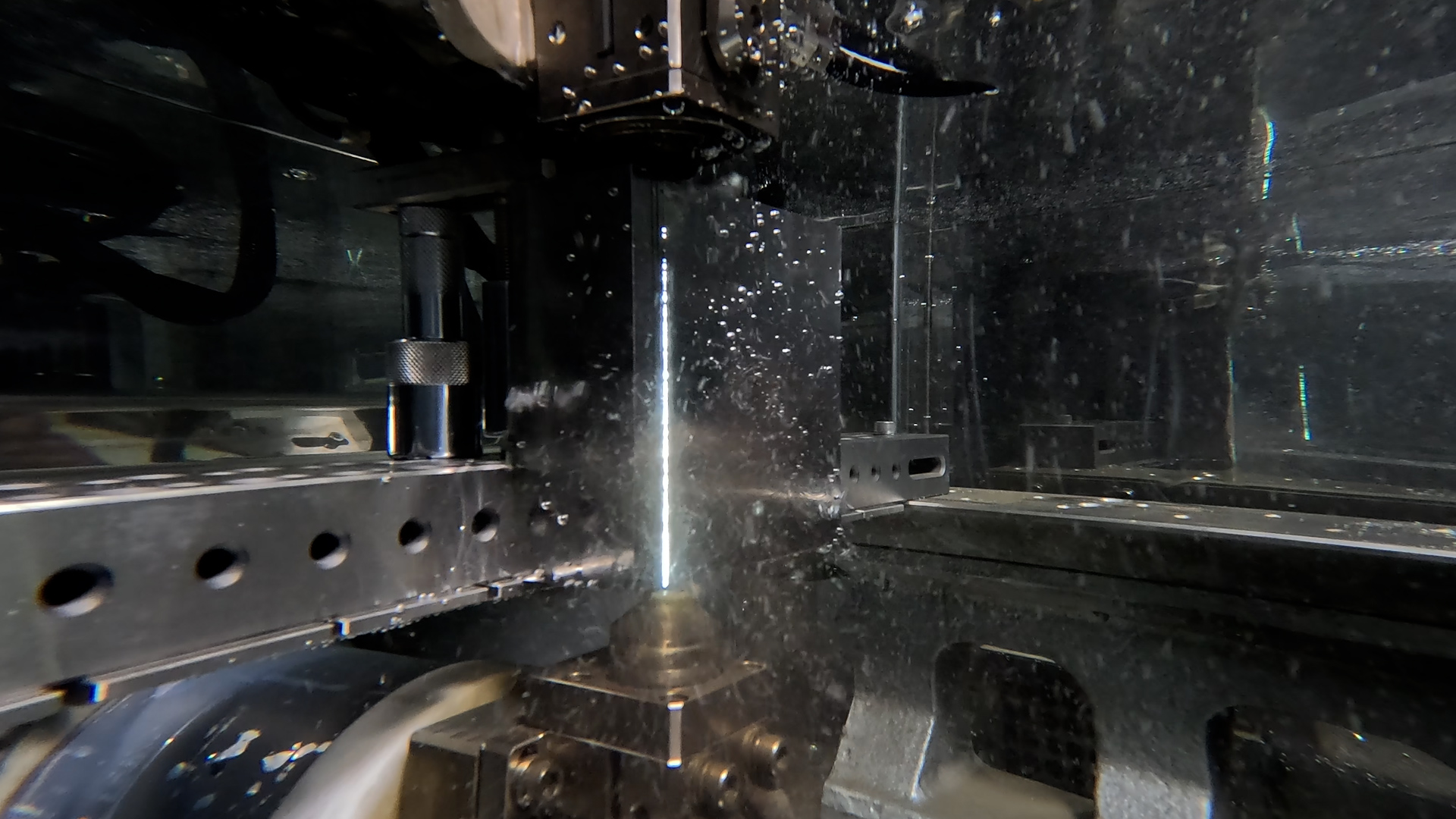

The Kmway EK Series Wire EDM is designed for manufacturers who prioritise accuracy, reliability, and cost-effectiveness. It features a compact build, advanced wire-threading system, and a robust thermally balanced frame. These attributes ensure that the machine offers precise and practical solutions to modern manufacturing challenges.

Key aspects of the EK Series include its Next-Generation Auto Wire Threading system, which maximises uptime and minimises operator intervention, even when flushing is not required. Additionally, the optional Linear Motor Drive provides frictionless motion, improving cutting accuracy and reducing wear compared to traditional systems.

The machine’s ultra-rigid frame ensures stability and consistent accuracy during prolonged or heavy-duty operations. Its compact design integrates an advanced filtration system that lasts significantly longer than typical filters, while the operator-friendly head design simplifies maintenance.

Kmway, with decades of EDM engineering experience, has developed this model to be energy-efficient, high-precision, and suitable for tight workshop spaces without compromising on performance. Now available in Europe, exclusively through Eurospark, the EK Series is expected to attract significant interest from manufacturers seeking reliable EDM solutions.

With new stock expected early next year, Eurospark is inviting inquiries from potential clients to discuss their specific requirements. For more information, interested parties are encouraged to contact Eurospark directly.

View more news from Eurospark LTD