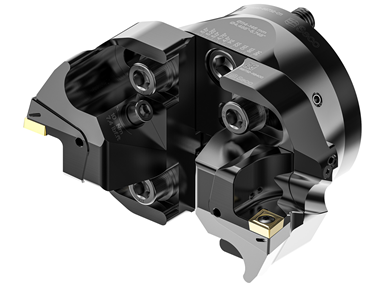

Seco BB732 Boring Bridges Deliver Stable, Vibration-Free Deep-Hole Machining!

Seco Tools has introduced its BB732 boring bridges, a modular solution developed to improve performance, stability and surface quality in demanding deep-hole boring operations. Designed for use with Steadyline vibration-damped boring bars, the BB732 system supports both roughing and finishing in a single setup, helping manufacturers reduce tooling complexity while maintaining high machining accuracy.

The BB732 boring bridges are engineered to work with the Steadyline SM40 shell mill holder and support large-diameter machining ranges. For roughing operations, the system accommodates diameters from 114 mm to 301 mm, while finishing operations can extend up to 315 mm. This wide coverage enables shops to handle a broad range of deep-boring applications without switching tools, reducing setup time and inventory requirements.

A key feature of the BB732 design is its conical-reinforced holder geometry, which delivers high static and dynamic rigidity. Combined with Seco’s Steadyline vibration damping technology, the system minimizes chatter and vibration even at long overhangs, supporting consistent dimensional accuracy and improved surface finishes. This stability is particularly valuable in deep-hole applications where tool deflection and vibration can quickly compromise part quality.

Coolant management is another central advantage of the BB732 system. The bridges feature optimized internal coolant flow that directs coolant precisely to the cutting edge. This targeted delivery helps control heat, improve chip evacuation and reduce the risk of chip packing—common challenges in deep boring. Improved cooling also contributes to longer insert life and more predictable machining performance.

The BB732 bridges are designed to handle both roughing and finishing tasks, eliminating the need for separate tools and simplifying process planning. Integrated safety features, including a built-in stopper that prevents block ejection due to centrifugal force, enhance operator safety during high-speed rotation.

According to Kavita Dandge, global product manager of machine solutions at Seco, the BB732 boring bridges are optimized to work seamlessly with Steadyline bars, particularly the SM40 series, for deep boring with large diameters. She highlights the directed coolant flow as a standout feature that supports effective chip breaking and thermal control at the cutting zone.

By combining rigidity, vibration damping, efficient coolant delivery and operational safety, the BB732 boring bridges provide a practical solution for manufacturers seeking reliable, high-quality results in deep-hole boring applications.