Blaser Swisslube Partnered With Nidec Machine Tool America to Deliver Integrated Metalworking Solutions!

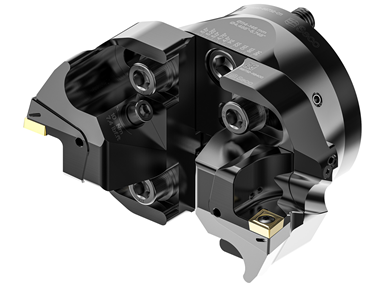

Blaser Swisslube and Nidec Machine Tool America announced a strategic partnership aimed at helping manufacturers achieve higher productivity, precision, and process reliability through tightly integrated machining solutions. The collaboration combined Blaser Swisslube’s Liquid Tool approach with Nidec Machine Tool America’s advanced gear manufacturing and precision machining technologies to deliver application-driven, measurable improvements on the shop floor.

Through this partnership, customers gained coordinated access to joint process evaluations designed to optimize the interaction between machines, cutting tools, and metalworking fluids. By aligning these critical elements, the two companies focused on improving overall machining stability, reducing variability, and enhancing process consistency in demanding production environments. The collaboration also included application-specific metalworking fluid recommendations, supported by on-site technical expertise to ensure fluids were correctly selected, implemented, and maintained for each machining process.

A key element of the partnership was the use of data-driven trials to validate performance improvements. These trials were designed to help manufacturers reduce cycle times, extend tool life, and achieve improved surface quality, while also lowering overall manufacturing costs. By evaluating real production data rather than relying solely on theoretical benchmarks, the companies aimed to deliver tangible productivity gains that could be sustained over time.

Carsten Witthuser, Head of the Americas at Blaser Swisslube Inc., stated that the partnership reflected the company’s commitment to working closely with machine tool builders that share a focus on performance and reliability. He emphasized that running Blaser Swisslube fluids continuously in Nidec machines allowed manufacturers to experience consistent results, improved uptime, and long-term value from their machining operations.

Scott Knoy, Vice President of Sales at Nidec Machine Tool America, noted that customers increasingly demand world-class precision and maximum equipment availability. He explained that aligning with Blaser Swisslube strengthened process performance by improving tool life, surface finish, and consistency, while simultaneously reducing the total cost of manufacturing.

As the partnership moved forward, both companies indicated they would continue collaborating on initiatives aimed at enhancing customer outcomes across a wide range of machining and manufacturing applications, reinforcing the role of integrated process optimization in modern, high-precision production environments.