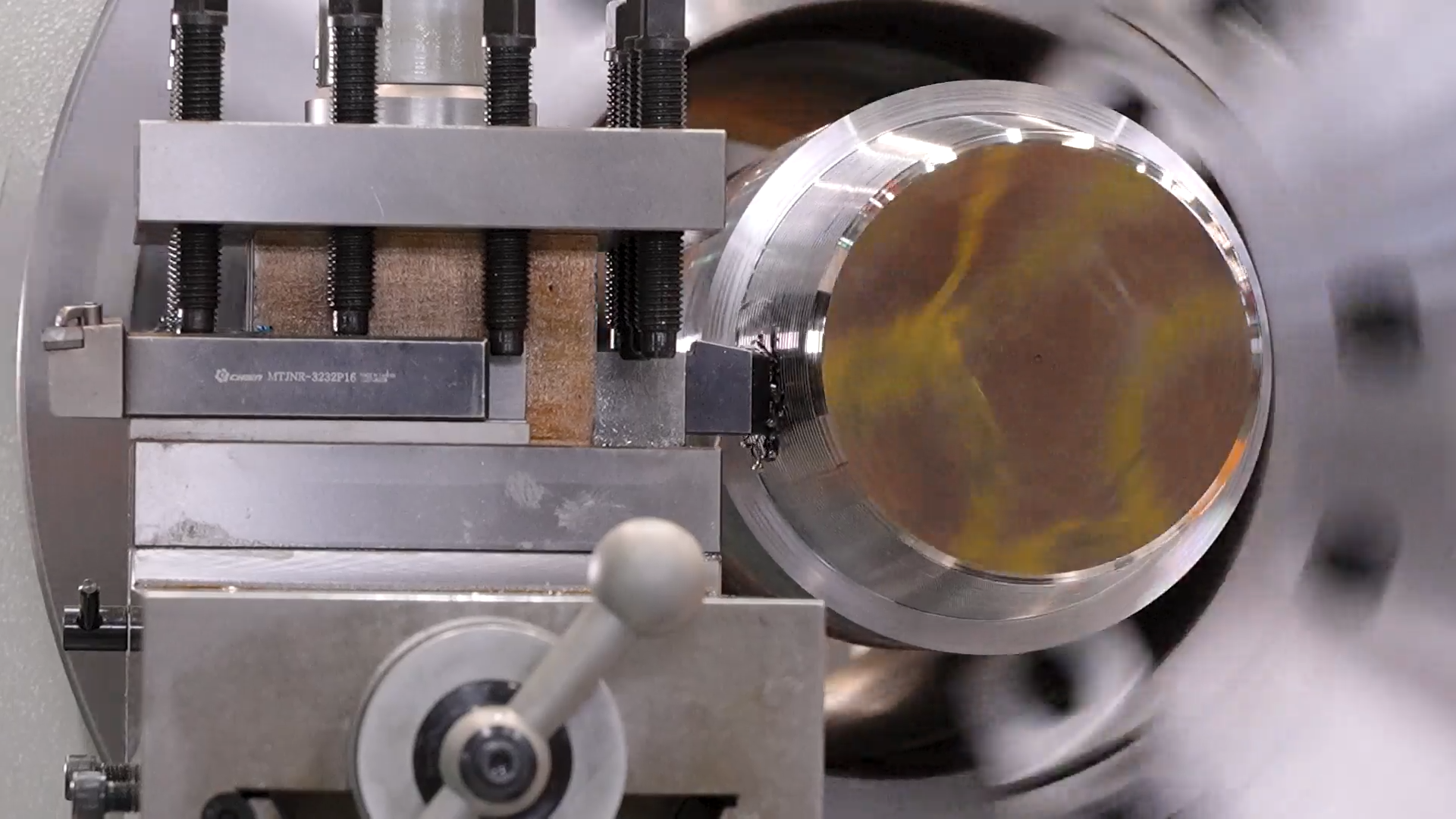

In response to the specific needs of a leading global manufacturer of electro-deposited copper foil, a dedicated grinding machine has been developed to enhance the production process. This innovative solution targets the critical requirement of surface consistency in industrial rollers, essential for maintaining top-quality copper foil.

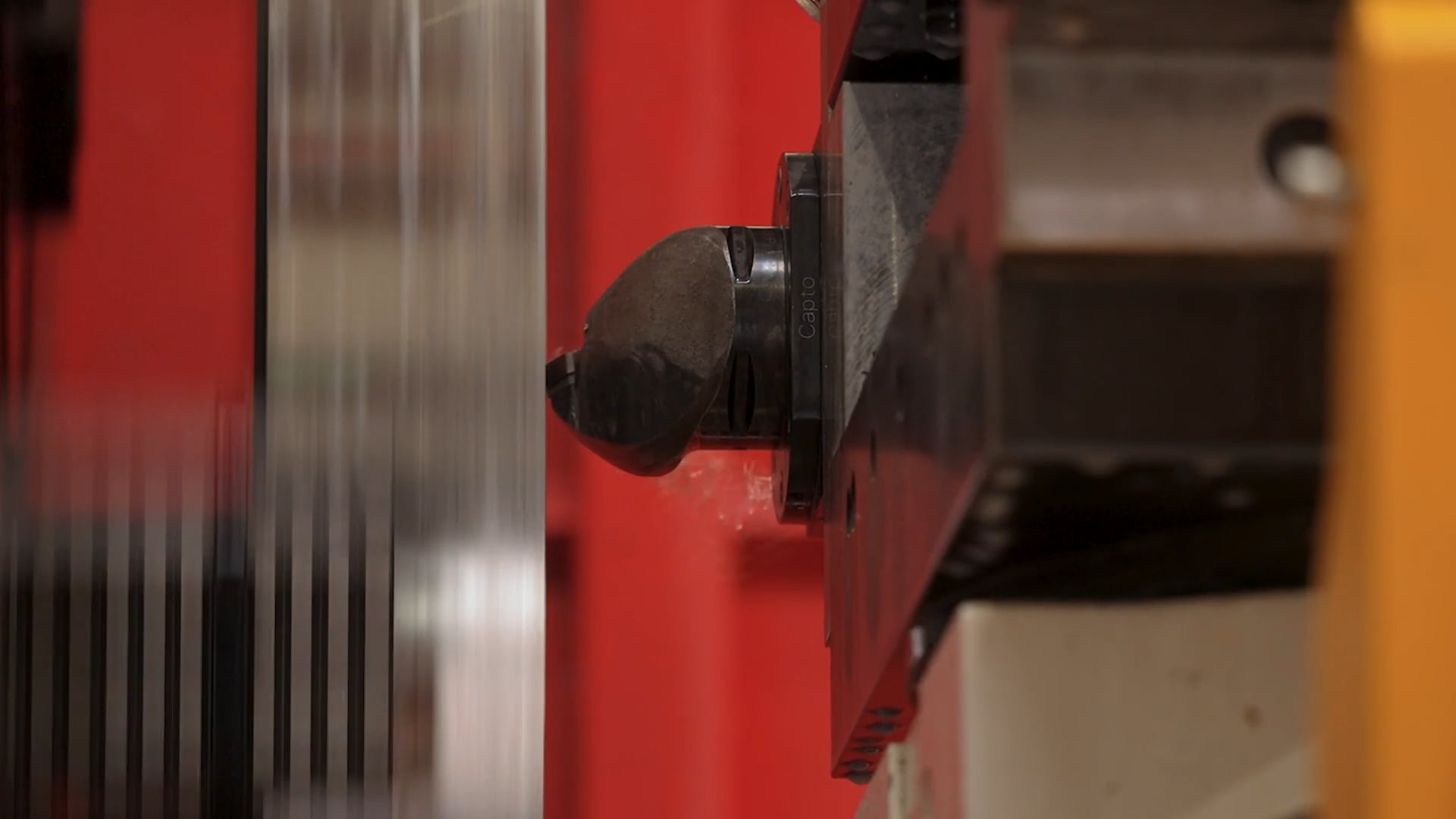

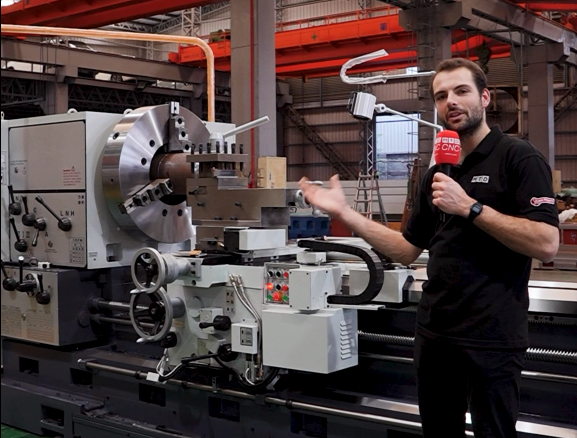

The new machine design is based on the MPA670.15.3 platform, with structural optimizations tailored for precision grinding. Key modifications include the removal of the traditional lathe compound rest, feed gearbox, and feed rod, simplifying the transmission chain and thereby increasing operational stability.

The drive configuration features a 2HP geared motor linked to a 50 mm lead screw. This setup, along with fixed bronze double nuts, guarantees smooth and precise linear motion. For enhanced stability during the process, a counterweight is installed at the rear of the saddle on the 16-inch bed platform, ensuring appropriate center-of-gravity balance during prolonged operations.

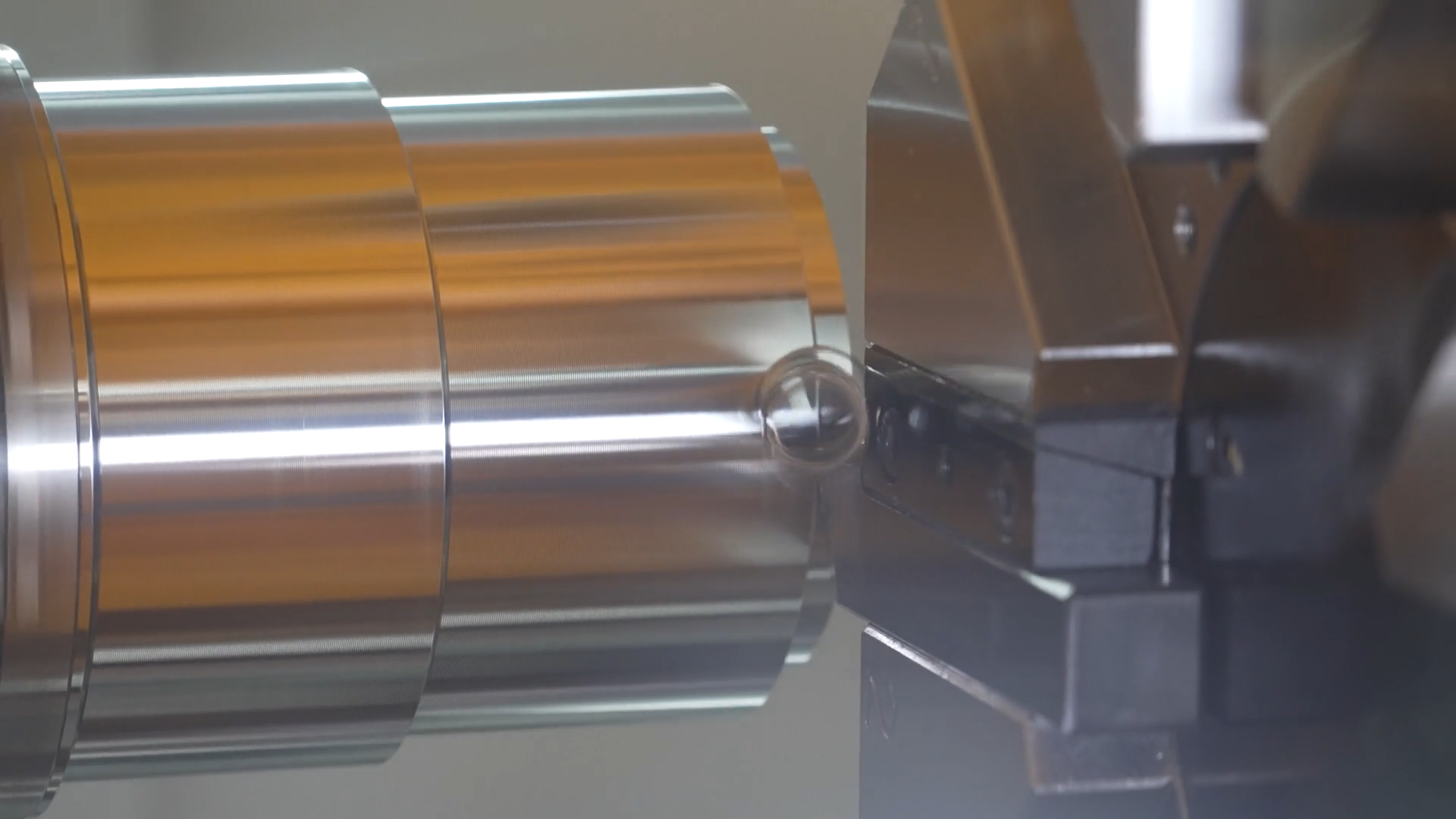

Operating parameters are finely tuned with a fixed spindle speed of 160 rpm and a Z-axis feed rate adjustable from 0.76 mm/s to 3.06 mm/s. Additionally, an integrated automatic stroke reversal system maintains consistent reciprocating movement within a set travel range.

This specialized machine is not designed for general shaft turning; rather, it is purpose-built for the copper foil industry and precision roller manufacturing. It supports long-stroke repetitive machining, achieving high consistency and repeatability thanks to its optimized mechanical balance and auto-reversal features.

MYDAY MACHINERY INC, the company behind this development, continues to lead in providing custom solutions to meet the specific needs of industries worldwide, further solidifying its reputation in precision grinding and industrial automation.

View more news from MYDAY MACHINERY INC