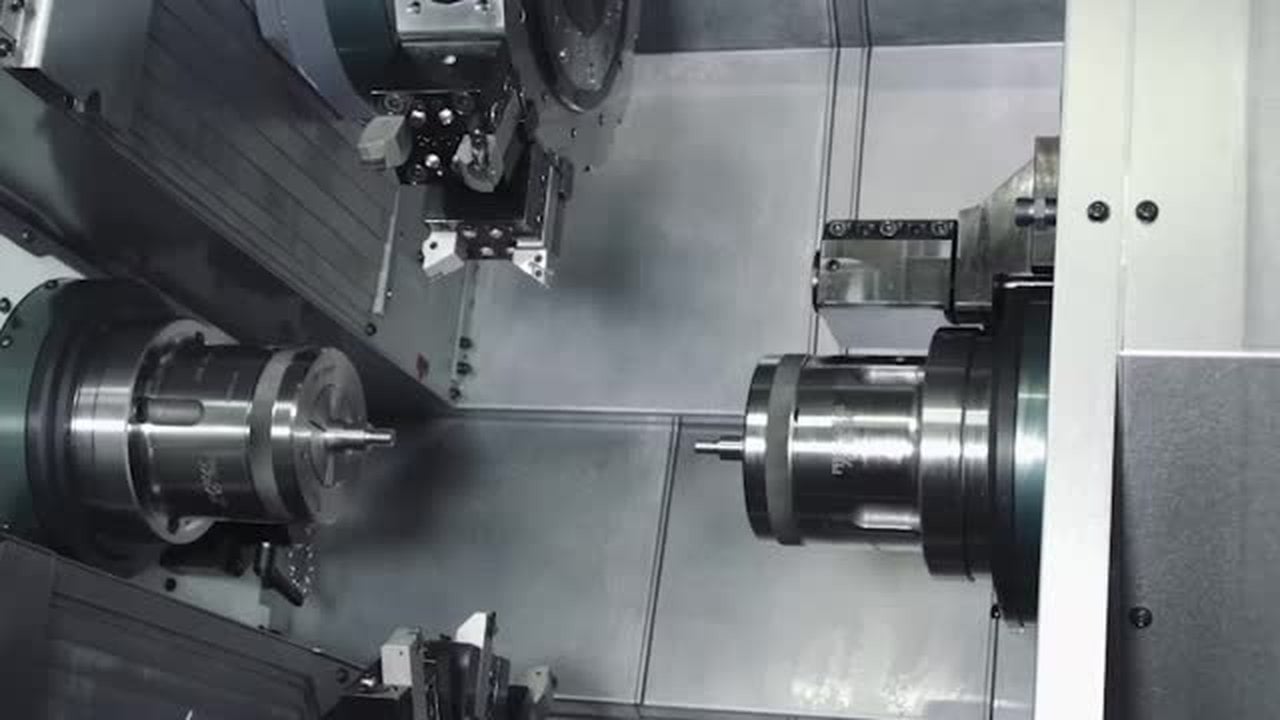

Swarf management is a critical aspect of CNC lathe operations, especially during threading processes. Accumulation of swarf, or metal debris, can pose significant challenges, including interference with loading, unloading, and transferring workpieces, as well as potential tool breakage. Addressing this issue is crucial for ensuring efficiency and safety in automated manufacturing environments.

CMZ, a renowned supplier of CNC lathes, has introduced oscillation cutting for threading. This technique enhances the efficiency, safety, and automation of CNC turning operations. By employing oscillation cutting, manufacturers can minimize swarf build-up, leading to smoother processes and reduced downtime.

The company offers a detailed technical document that provides valuable programming tips to maximize the benefits of oscillation cutting. This resource aims to assist manufacturers in overcoming swarf-related challenges, ultimately enhancing productivity and equipment lifespan.

With a strong emphasis on innovation, CMZ continues to support industrial advancements by delivering solutions tailored to the evolving needs of the manufacturing sector.

View more news from CMZ