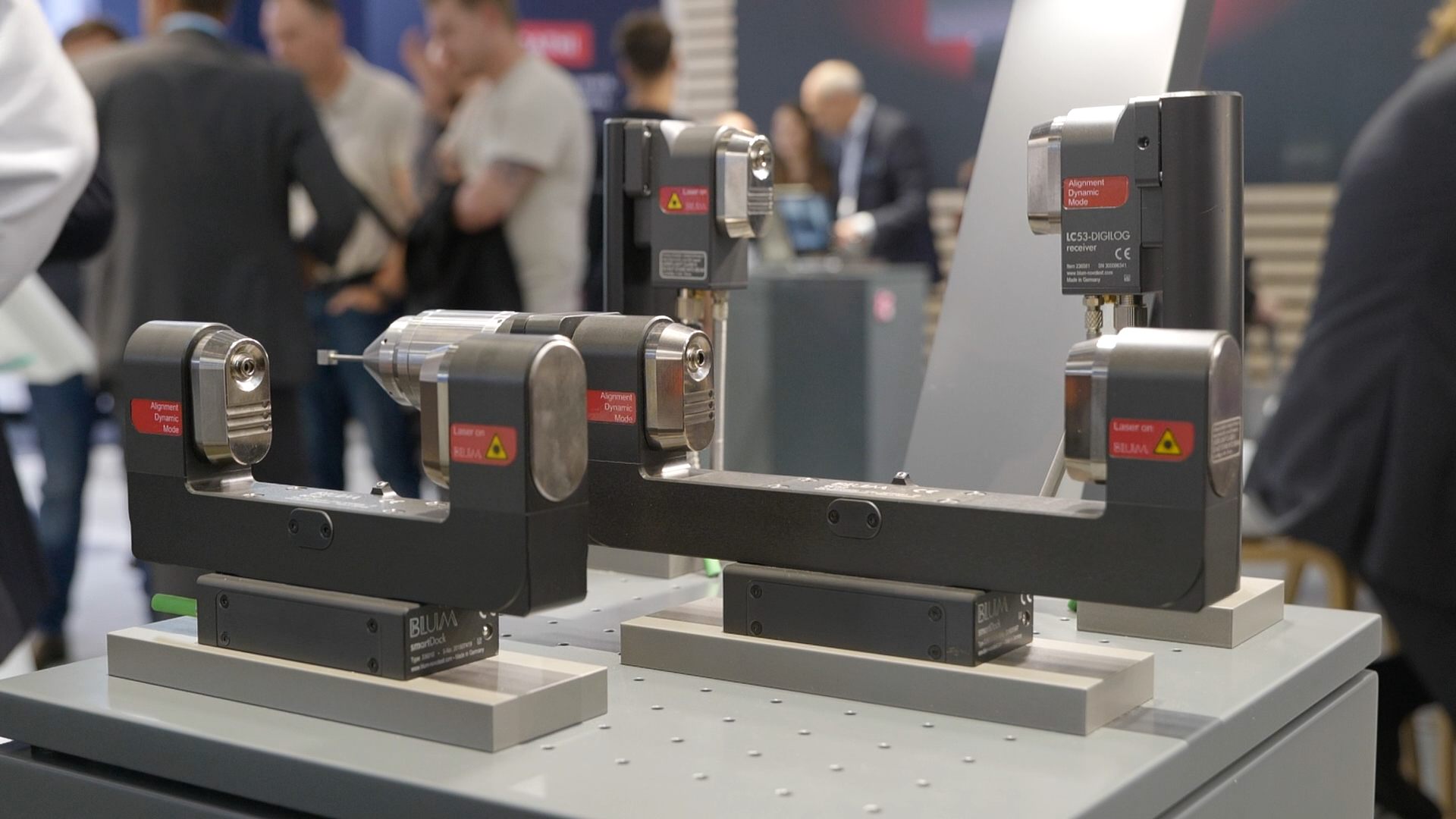

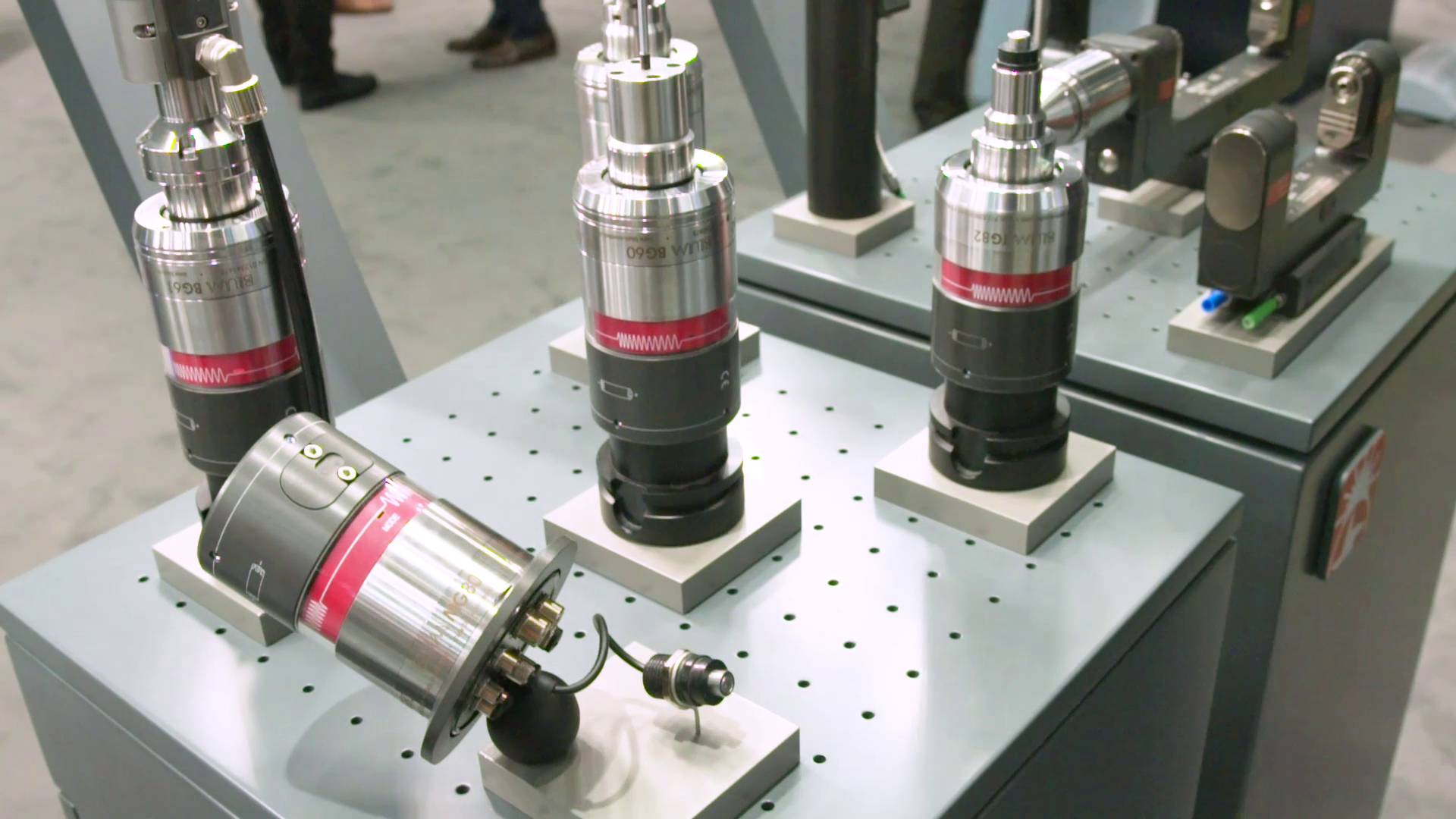

Blum-Novotest has unveiled the TC76-DIGILOG scanning touch probe, designed to enhance serial production processes. This innovative tool is set to redefine how companies integrate measurement solutions into machining operations, ensuring stable processes and reliable quality assurance in continuous production environments.

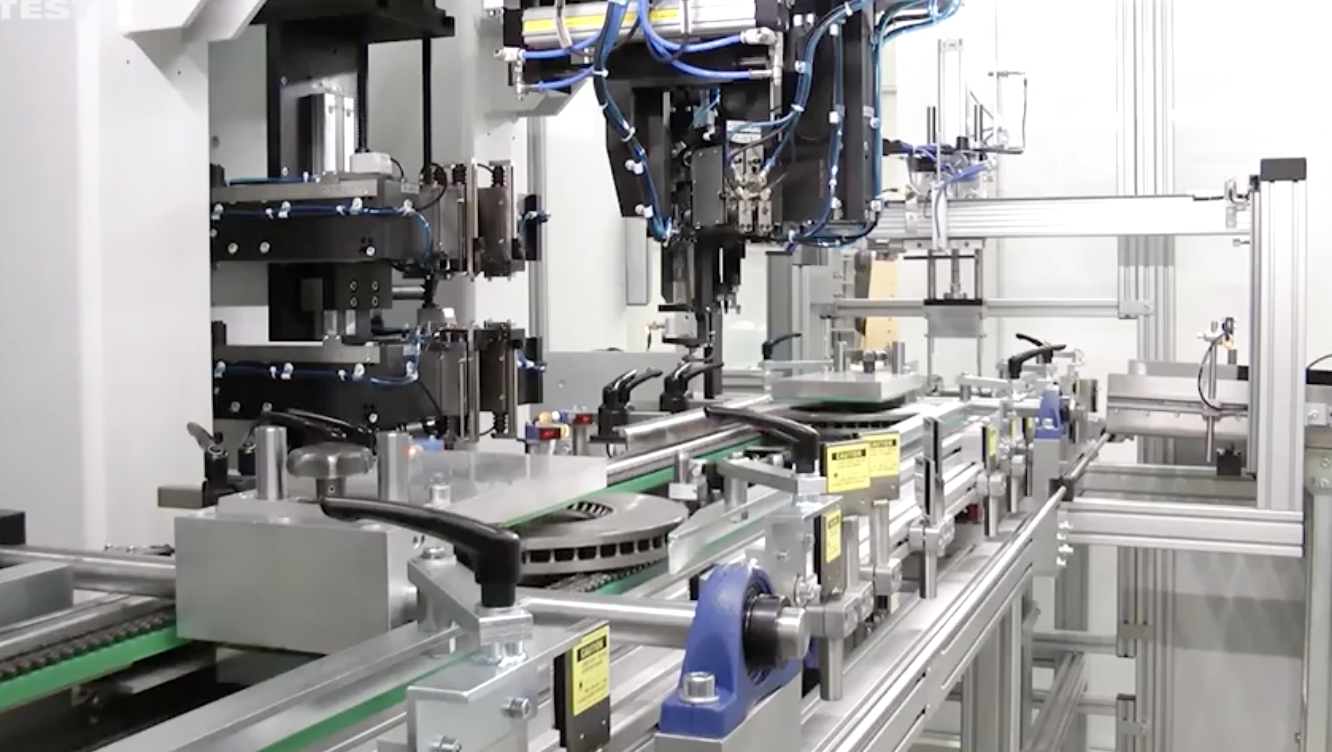

Karlheinz Lehmann GmbH recently implemented the TC76-DIGILOG touch probe to inspect the dimensional accuracy of complex contours directly in the lathe. This was particularly crucial during the production of a quick release coupling for compressed air applications. The probe’s ability to provide reliable measurements under demanding conditions underscores its suitability for high-stakes manufacturing tasks.

The introduction of the TC76-DIGILOG exemplifies Blum-Novotest’s commitment to combining general serial production needs with tailored measurement solutions. The probe is not only practical and process-reliable but also focuses on enhancing overall productivity. These attributes make it an ideal choice for manufacturers looking to optimize their quality assurance systems.

Blum-Novotest is renowned for its expertise in innovative metrology solutions, continually pushing the boundaries of what is possible for industrial applications. The addition of the TC76-DIGILOG scanning touch probe further solidifies the company’s position as a leader in providing cutting-edge tools for the manufacturing sector.

View more news from Blum-Novotest GmbH