MTDCNC Visits Universal Fabrications to Showcase Advanced Microloc Workholding on New Matsuura 5 Axis Machines

By Alison Green

MTDCNC recently visited Universal Fabrications for a technology focused shop floor tour highlighting the company’s latest investment in advanced workholding and five axis machining. Chris, Alison and Rowan from the MTDCNC team spent the day with the Universal Fabrications engineers exploring how new Microloc systems are enhancing productivity, accuracy and flexibility across the business.

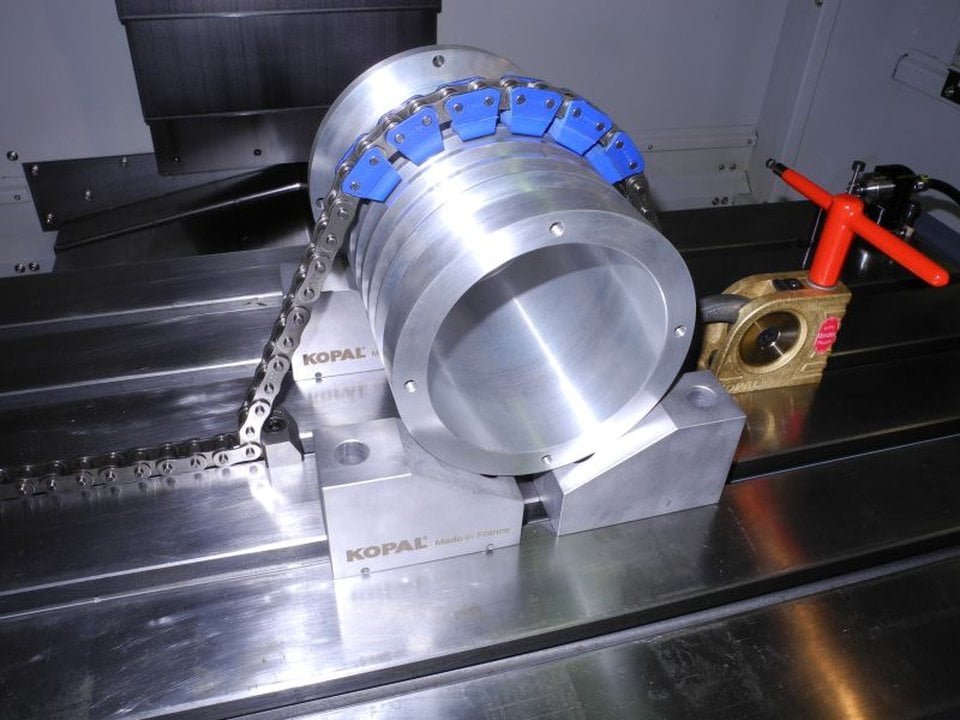

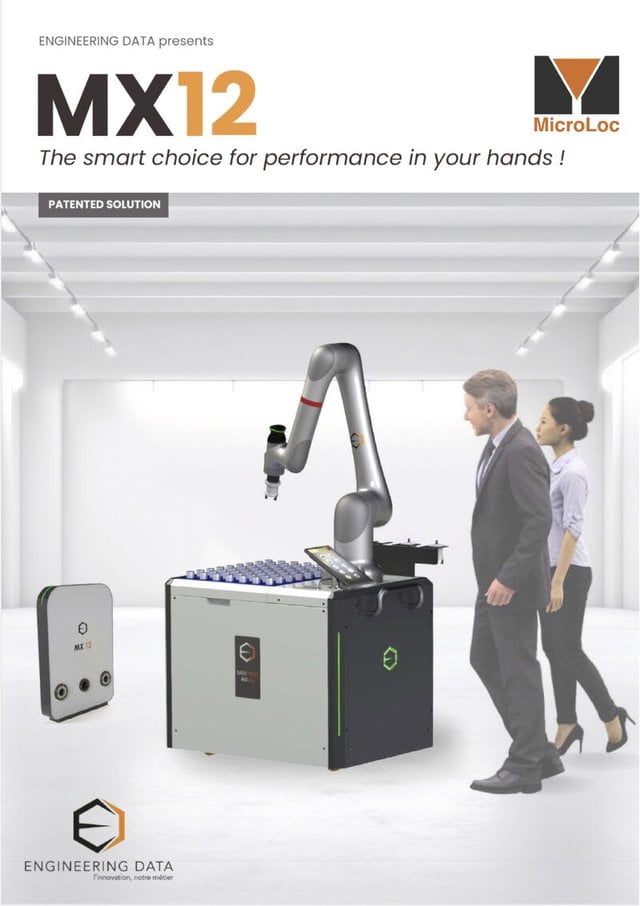

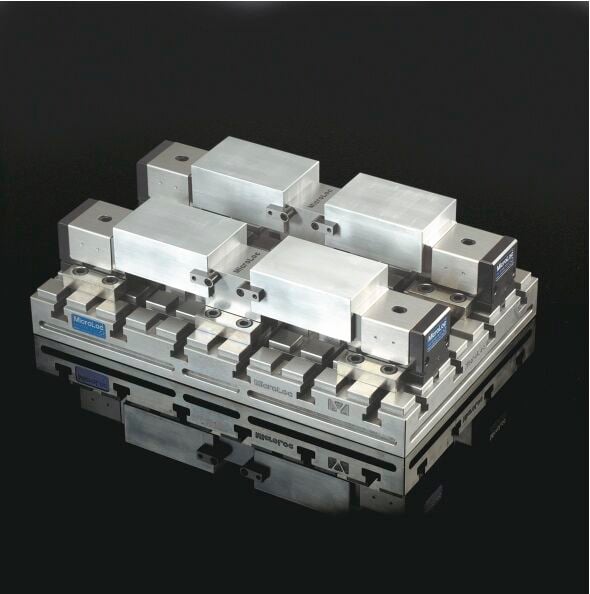

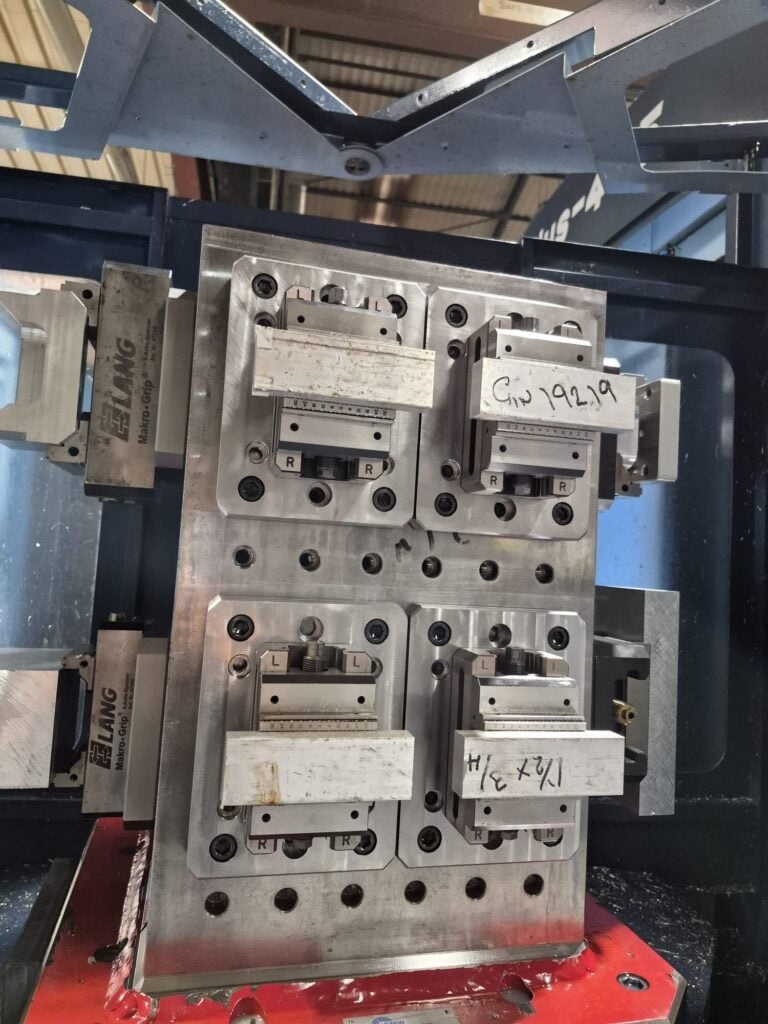

The visit centred around the integration of Microloc’s new 5 axis vices and manual zero point systems on two recently installed Matsuura machines. This combination is designed to deliver faster setup times, secure and repeatable clamping, and greater confidence when moving components between operations. The result is a more streamlined workflow that supports both complex one off parts and repeat production runs.

By pairing high performance five axis platforms with a modern, modular workholding approach, Universal Fabrications is building a manufacturing environment focused on efficiency and consistency. The Microloc zero point systems in particular are enabling quicker changeovers and improved process reliability, key factors in maintaining competitiveness and meeting demanding customer expectations.

About Universal Fabrications

Successfully trading for over 45 years, Universal Fabrications is a well established trade manufacturer of sheet metal fabrications and precision machined components. The company is regarded by its customers as an integral part of their supply chain, known for reliability, quality and a proactive approach to problem solving.

Their team takes great pride in the work they produce and internally describe themselves as “All in”, a reflection of their commitment to customers and continuous improvement. Ongoing investment in machinery, people and facilities ensures Universal Fabrications remains well positioned to support both current and future manufacturing demands.

The MTDCNC team noted the strong engineering culture and forward thinking mindset throughout the visit, with technology investments clearly aligned to long term capability growth.

This latest upgrade demonstrates how strategic investment in both machine tools and workholding can unlock greater performance on the shop floor, reinforcing Universal Fabrications’ position as a trusted and capable UK manufacturing partner.