The theme this year on Hurco Europe’s 216 square metre stand (Hall 19-140) will be ‘Smarter CNC for Smarter Shops’, emphasising that the company’s machine tools are intelligent, intuitive and operator-friendly, so reliance on specialist programmers is reduced.

The company’s managing director David Waghorn comments, “Subcontractors are often faced with high-mix, low-volume production requirements and every new job is different. Getting from the initial idea to the finished part in the fastest possible time is the key to maximising profitability. This is where the Hurco product range shows its greatest strength.”

As ever, the manufacturer’s proprietary WinMax software will be a primary focus, as it is at the core of a user’s ability to compress lead-times. Widely regarded as one of the most flexible CNC systems in the industry, it bridges the gap between conversational and G-code programming. Arguably the software’s killer feature is the ability to merge the two data sets, enabling complex CAM-generated 3D surfaces to be inserted into a conversational program, or conversational content to be added to an NC program, resulting in a high degree of versatility.

There is much more to the control software, which can be reviewed here:

www.hurco.com/gb/products/Pages/WinMax-our-cnc-control.aspx, solid model import being a stand-out attribute. Anecdotal comments from operators on the shop floor highlight another feature that make their life easier – the Interrupt Cycle. It allows the tool to be jogged away from a component so that an insert or the cutting edge can be checked, after which pressing a single button returns the cutter automatically and precisely to the original point to resume the cycle. It is a luxury not found on many control interfaces.

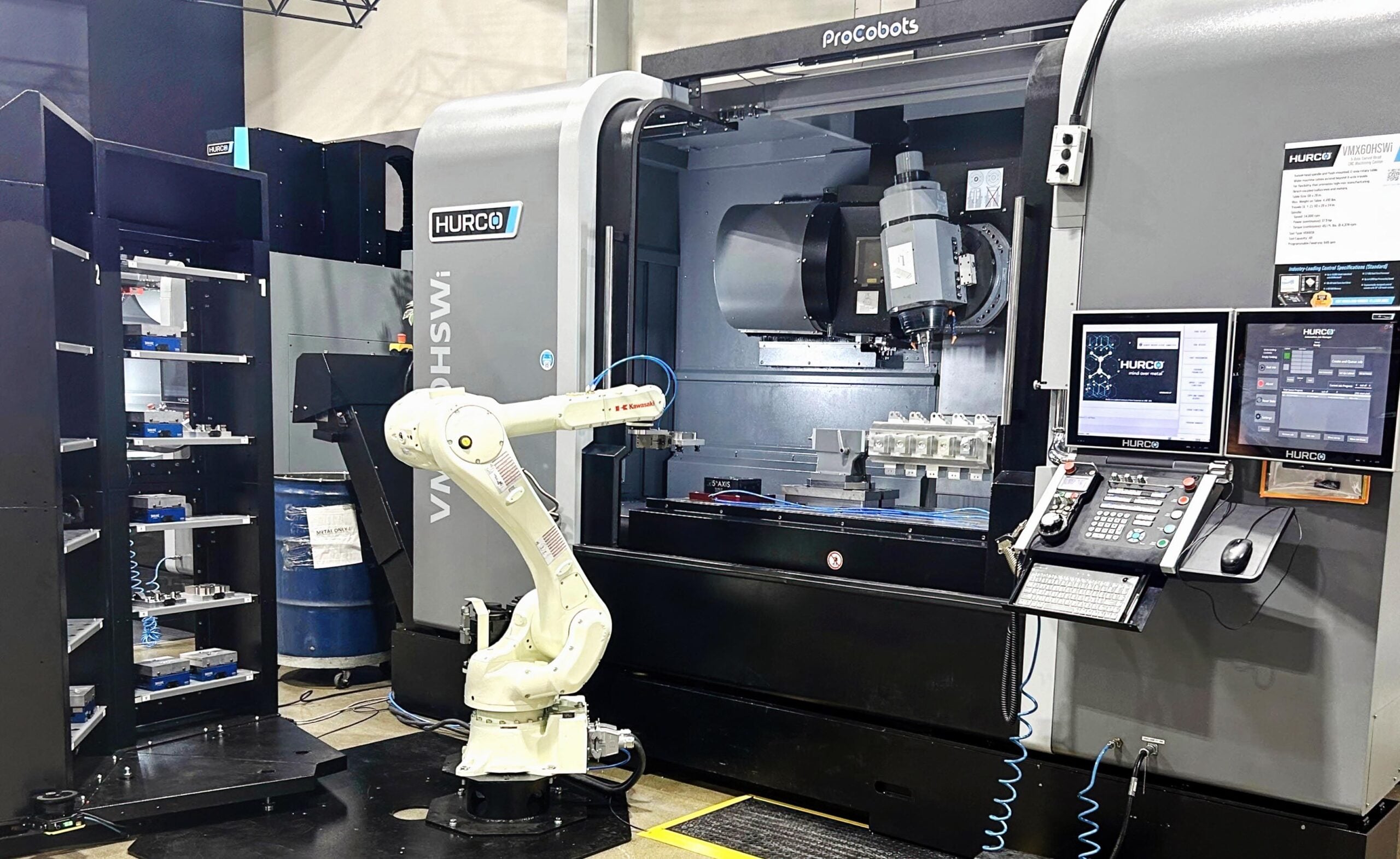

Machine tool exhibits to include new automated production cell

On the stand will be Hurco’s first-ever machine tending cell based on a 6-axis industrial robot, which will be offered as a standard package. It will comprise a cantilever-design 5-axis VC500i machining centre equipped with a Kawasaki PC 25 system. It is the first offering to result from the strategic collaboration between Kawasaki Robotics and Hurco that was announced at IMTS 2024. The cell is an automation solution that combines the additional load-capacity of an industrial robot with easy-to-use, app-based programming at the Hurco control.

The flexible solution allows various pallet, fixture and component combinations weighing up to 25 kg to be delivered to the machine from the heavy-duty rack system. In addition to long production runs, the solution lends itself ideally to the automation of one-offs and small-batches. As the robot is programmed with the same user-friendly Hurco software as is used for the cobots, less than one day’s training is required for an operator to become proficient.

Hurco will also be showing a VMX30Ui trunnion-type 5-axis machine and a pair of 3-axis vertical machining centres, a VM10i and a larger VM20i automated with a ProCobot Profeeder-X 10-drawer system. CNC lathes, which are a growing part of the company’s turnover, will be represented by two driven-tool models, a TM8Mi and a TMX8MYSi, the latter having Y-axis turret motion and a sub spindle.

Under a long-standing agency agreement that has spanned more than 20 years, Hurco Europe has been the exclusive sales and service agent in Britain and Ireland for 3-axis and 5-axis, high-speed machining centres built by German firm, Roeders. To be exhibited for the first time in the UK will be the RPT450DS EcoSpray, a 5-axis machine capable of milling, jig grinding and measuring. It is able to maintain super-high precision even under variable ambient temperature conditions.

The DS suffix signifies dual support for the swivelling of the rotary table, providing superior stability for 5-axis simultaneous machining, while EcoSpray refers to a patented tool cleaning and minimum quantity lubrication system integrated into the machine.

It will be the first time that any premium line machine from the Roeders RPT range will have been on show in the UK. While the established RXP series was already world-class, the new series features Precitemp technology designed to halve the achievable tolerances, moving from micron-level precision into the sub-micron and nanometre realms.