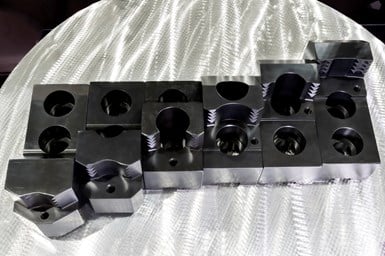

Dillon Manufacturing Claw Jaws Drive Higher Productivity in Turning Operations!

Dillon Manufacturing Inc. has developed its claw jaws to address one of the most persistent challenges in turning operations: achieving maximum clamping force without compromising cycle time, accuracy, or tool life. Designed specifically for demanding machining environments, these claw jaws enable shops to push more aggressive cutting parameters while maintaining secure workpiece holding, directly translating into improved throughput and operational efficiency.

At the core of the claw jaw design is a carefully engineered balance of contour, mass, and center of gravity. Dillon has optimized these factors so that cutting forces generated during turning are converted into additional gripping force rather than causing slippage or vibration. This self-reinforcing behavior allows machinists to increase feed rates and depth of cut with confidence, reducing overall cycle times while maintaining consistent dimensional accuracy. By minimizing loss of holding power during heavy machining, the jaws help stabilize the process even in high-load or interrupted cutting applications.

The claw jaws are designed to apply strong and uniform clamping pressure on both the outer diameter (OD) and inner diameter (ID) of the workpiece, making them suitable for a wide range of turning tasks. This versatility allows shops to standardize on a single jaw solution for multiple setups, reducing changeover time and simplifying inventory management. Compatibility with most standard chucks further enhances ease of integration, enabling users to upgrade existing machines without significant modifications or additional investment.

Flexibility in setup is another key advantage of the claw jaw system. Clamping depth can be adjusted using workpiece stops, giving machinists the ability to fine-tune part positioning based on specific job requirements. This adaptability is particularly valuable in high-mix environments, where shops frequently switch between different part geometries and materials. Dillon offers a broad selection of standard jaw sizes to cover common applications, while also providing custom designs at no additional engineering cost. This approach allows customers to tailor workholding solutions to unique parts without extending lead times or increasing tooling expenses.

Durability is a critical factor in workholding performance, and Dillon Manufacturing addresses this through material selection and manufacturing quality. The claw jaws are produced from 8620 steel, a material known for its strength, toughness, and resistance to wear. This ensures long service life even in high-production environments where jaws are subjected to repeated clamping cycles and heavy cutting loads. The robust construction helps maintain consistent gripping performance over time, reducing the frequency of jaw replacement and lowering overall tooling costs.

Made in the United States, Dillon’s claw jaws are designed to support shops that prioritize reliability, fast delivery, and dependable after-sales support. By combining strong clamping performance with flexible configuration options and durable construction, the jaws help manufacturers improve spindle utilization, reduce scrap, and achieve more predictable machining outcomes. Across industries ranging from general machining to high-volume production, Dillon Manufacturing’s claw jaws provide a practical solution for shops seeking to boost efficiency, shorten cycle times, and maintain control in increasingly demanding turning applications.