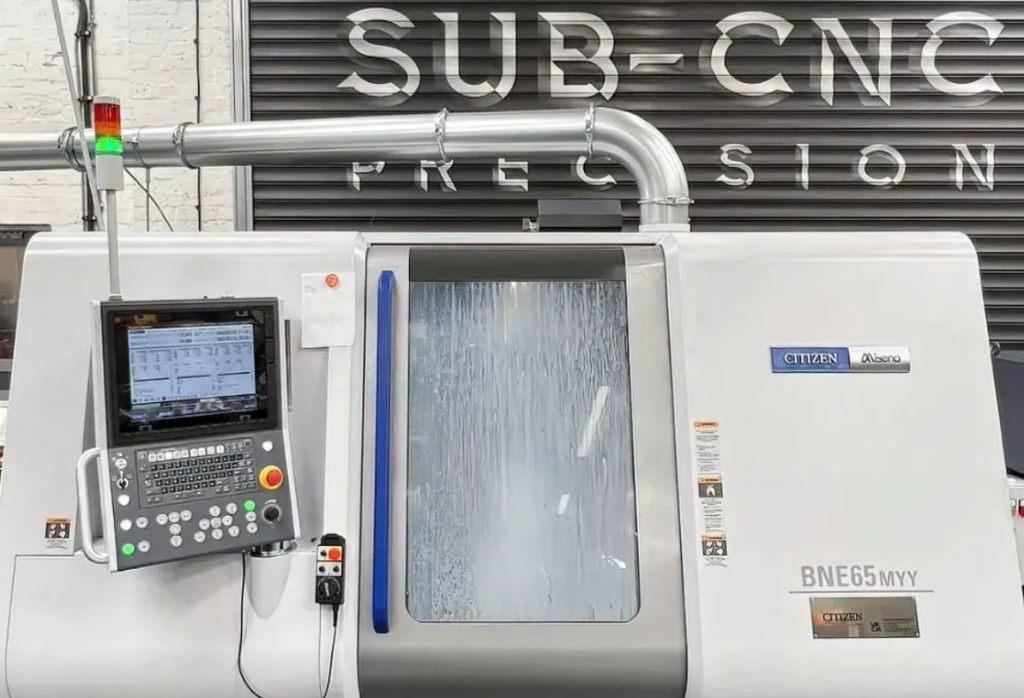

How Sub-CNC Precision turned early risk into long-term manufacturing success

Starting a new subcontract machining business in 2008, just as the global financial crisis took hold, was not an obvious move. For many, it was a time to pause investment and minimise risk. For Sub-CNC Precision, however, it marked the beginning of a journey defined by confidence in engineering, commitment to quality, and a clear belief in the power of the right technology.

Founded in Luton by Yian Stavrou and George Dingley, the business began life as a turned parts subcontractor with ambitions that extended well beyond survival. From the outset, the pair focused on one core principle: invest in machine tools and processes capable of delivering absolute reliability, precision, and productivity.

That philosophy led them, almost instinctively, to Citizen Machinery UK.

A Partnership Built Over Time

More than fifteen years on, Sub-CNC Precision has purchased 25 Citizen machines, part-exchanging a small number along the way to leave 21 Citizen lathes on the shopfloor as of November 2025. Around two-thirds are Cincom sliding head machines, capable of producing parts from 0.5mm up to 38mm diameter, while the remainder are Miyano fixed head turning centres.

This core turning capacity is supported by a wider CNC infrastructure that includes additional fixed head turning, vertical machining centres with fourth axis capability, a CNC cylindrical grinding machine, and even additive manufacturing via a 3D printer. In total, 27 CNC machine tools operate on site.

The result is a factory designed for flexibility, but optimised for volume.

Sub-CNC serves a broad range of demanding industries, including aerospace and defence, automotive and motorsport, telecommunications, sensors, energy and renewables, hydraulics, medical, and instrumentation. ISO 9001 accreditation and JOSCAR registration reflect the company’s commitment to quality and traceability, while long-term contracts demonstrate customer confidence.

Lights-Out Manufacturing as Standard

Many of the lathes at Sub-CNC run continuously, operating lights-out from 6.00pm through to 7.00am. Unattended machining is not treated as an exception, but as a normal and essential part of remaining competitive.

A major enabler of this approach was the early adoption of Citizen’s LFV (Low Frequency Vibration) chip-breaking technology. In 2017, Sub-CNC installed one of the first LFV-equipped machines in the UK, quickly followed by a second later the same year.

Yian Stavrou recalls the impact clearly. LFV transformed the ability to machine materials that traditionally generate long, stringy swarf — the kind that forces operators to stop machines and intervene manually. Instead, LFV breaks chips into short, controlled segments, allowing machining to continue unattended with confidence.

For Sub-CNC, this was not simply a technical improvement; it was a competitive necessity. The ability to run overnight, reliably and repeatedly, even on difficult materials, has become fundamental to maintaining UK manufacturing competitiveness in the face of low-cost overseas labour.

Tackling Difficult Materials with Confidence

The benefits of LFV were immediately apparent when machining copper and phosphor bronze, materials notorious for producing continuous coils of swarf. But its usefulness quickly extended far beyond that.

Sub-CNC now routinely applies LFV when machining stainless steels, aluminium, plastics, and high-performance materials such as Monel, Inconel, titanium alloys, and other exotic metals, including those destined for submarine and defence applications.

The flexibility of LFV programming is key. Using simple G-code commands, the function can be switched on and off during a cycle and adjusted to produce different chip sizes. This allows Sub-CNC to maximise productivity, applying LFV only where chip control is required and disabling it elsewhere to avoid unnecessary cycle time penalties.

Today, more than half of Sub-CNC’s sliding head lathes are equipped with LFV, and no new Cincom enters the factory without it.

Engineering Detail That Makes the Difference

Beyond LFV, Sub-CNC values several other Citizen design features that directly impact efficiency and cost control. High-pressure coolant delivery — up to 140 bar — assists chip evacuation, particularly during parting-off operations. Removable guide bushes offer further flexibility, allowing the use of lower-cost bar material when appropriate and reducing bar remnant waste.

This configuration is especially effective for components whose length is less than 2.5 times their diameter, where radial deflection is minimal even without guide bush support. These seemingly small design considerations accumulate into significant productivity and cost advantages over time.

Expanding Fixed Head Capability

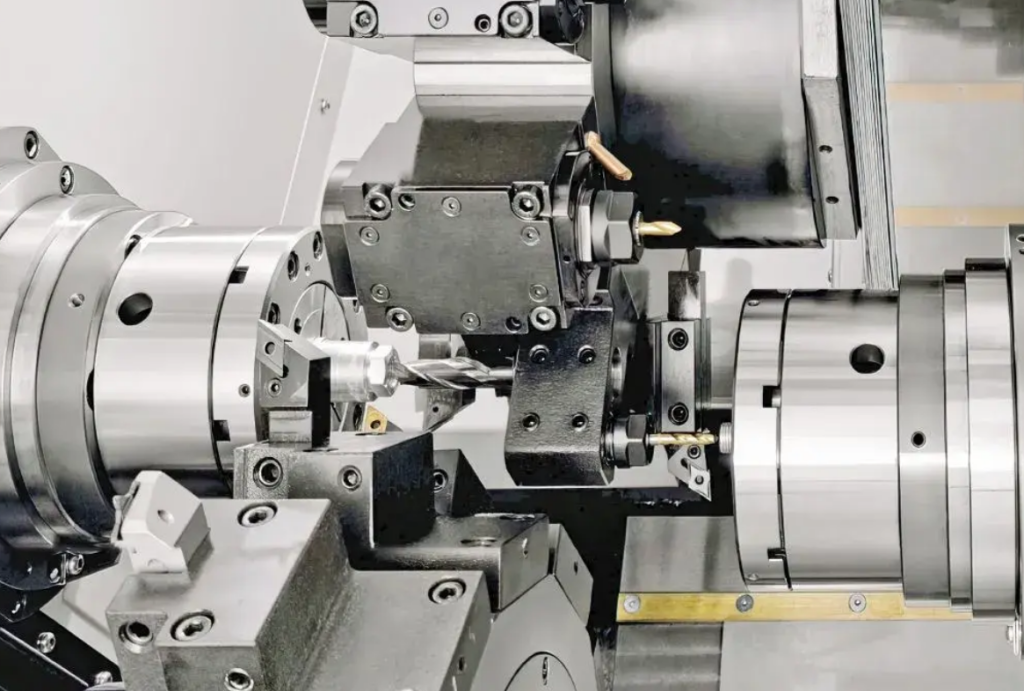

While sliding head machining forms the backbone of the operation, fixed head turning has also played a crucial role in Sub-CNC’s growth. The first Miyano machines arrived in 2012, initially supporting complex turn-milled components for the oil and gas sector.

Capacity has steadily expanded since then. Recent additions have extended bar capacity up to 65mm, and billet machining up to 200mm diameter, enabling Sub-CNC to take on increasingly complex, high-value components.

Advanced configurations — including dual Y-axis turrets — allow simultaneous machining with multiple tools in cut, reducing cycle times dramatically. In one notable aerospace application, a complex aluminium component previously requiring multiple milling operations elsewhere was completed in a single seven-minute cycle, with sufficient process reliability to allow unattended overnight running.

Skills, Systems, and Quality at the Core

Sub-CNC employs 22 people, many of whom have developed their skills through the company’s internal apprenticeship scheme and links with Dunstable Technical College. Engineering capability is reinforced by digital systems, including Fitfactory production control and MRP software, enabling flexible logistics solutions such as consignment stock, kanban, just-in-time delivery, and spot order fulfilment.

Quality assurance underpins everything. A dedicated inspection room supports rigorous pre-production review, first-off inspection, and in-process measurement using touch probe and optical equipment. Full traceability is maintained from raw material receipt through to final despatch.

Volume Where It Matters — Flexibility Where It Counts

High-volume production is a defining feature of Sub-CNC’s business. Current contracts include 20,000 stainless steel automotive components per week, 3,000 complex sensor components weekly, and 10,000 brass parts per month for oil and gas applications.

Yet the company remains equally comfortable supporting design, prototyping, and short-run production, often producing runs of just 10–20 parts on sliding head lathes. Many of these projects evolve into long-term, high-volume contracts — a testament to the trust built early in the development cycle.

The Right Decision, Proven Over Time

Both founders are time-served mechanical engineers with early experience running Cincom machines at other subcontractors. Their confidence in Citizen technology was earned long before Sub-CNC existed.

Looking back, Yian Stavrou is clear in his assessment. Choosing Citizen at the outset was not just the right decision — it shaped the entire business.

Properly set up, he says, Cincom and Miyano machines simply keep producing. Hour after hour, shift after shift, delivering consistent quality and single-figure micron tolerances until the bar magazine runs empty.

For a company born in a downturn, that reliability has been the foundation of sustained growth — and a powerful reminder that in manufacturing, precision is not just a specification, but a strategy.