America Makes to Host 2026 Additive in Steel Competition During TRX at RAPID + TCT!

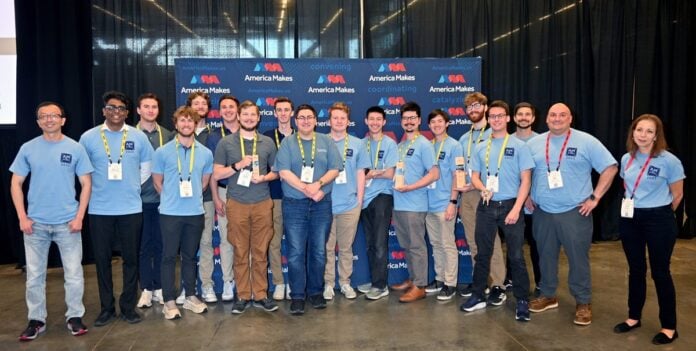

America Makes has announced that its 2026 Additive in Steel Competition will be held on April 15, 2026, in Boston, Massachusetts, during its spring Technical Review and Exchange (TRX), co-located with RAPID + TCT 2026. The TRX event will run from April 14 to April 16 alongside RAPID + TCT, North America’s largest event dedicated to additive manufacturing and industrial 3D printing. The competition continues America Makes’ focus on advancing additive manufacturing technologies while building a strong, skilled future workforce for the industry.

Following the success of last year’s co-location, America Makes and SME will once again bring together stakeholders from industry, academia, and government in a single venue. This continued collaboration is intended to enhance knowledge exchange, encourage cross-sector partnerships, and accelerate the transition of additive manufacturing innovations from research to real-world application. By aligning the competition with TRX and RAPID + TCT, America Makes is positioning student talent and emerging ideas at the centre of the broader AM ecosystem.

The 2026 Additive in Steel Competition builds on the foundation established in 2025 and reinforces America Makes’ long-term commitment to talent development in metal additive manufacturing. The challenge invites university student teams to design and fabricate a functional everyday carry (EDC) multi-tool using steel-based additive manufacturing processes. Unlike conceptual design exercises, the competition emphasizes end-to-end execution, requiring teams to move from design and engineering through fabrication, documentation, and performance testing.

A defining element of the challenge is its real-world orientation. Student teams are encouraged to collaborate with first responders, military personnel, and other service professionals to ensure that their designs address practical operational needs. This user-informed approach is intended to help participants understand how additive manufacturing can solve real problems while balancing performance, manufacturability, and material constraints. By focusing on steel-based AM, the competition also highlights the growing importance of advanced steels in demanding applications where strength, durability, and reliability are critical.

The competition draws inspiration from the long history of multi-tools, which date back to ancient times, including a Roman folding utensil from around 200–300 CE. Modern multi-tools, most notably the Swiss Army Knife introduced in the late 19th century, transformed portable utility through compact, multifunctional design. By challenging students to reinterpret this concept using additive manufacturing and steel, America Makes is linking historical engineering ingenuity with next-generation manufacturing technologies.

According to Ben DiMarco, Technology Transition Director at America Makes, inspiring the next generation of engineers and designers is essential for the future of the additive manufacturing industry. He noted that the competition serves as a launchpad for young innovators to develop hands-on skills, collaborate across disciplines, and explore what is possible when advanced design meets modern manufacturing methods.

The competition timeline is structured to guide teams through the full development cycle. Proposed teams and preliminary plans are due by February 13, followed by a virtual “Meet the Judges” session on March 10. Final submissions, including the completed multi-tool, technical report, and project video, must be submitted by April 1. Performance testing and the awards presentation will take place live on April 15 during TRX.

Three awards are anticipated, along with two honorable mentions for teams that successfully complete all phases of the project. Through this initiative, America Makes continues to strengthen the pipeline of skilled additive manufacturing professionals while reinforcing the role of steel AM in practical, high-performance applications.