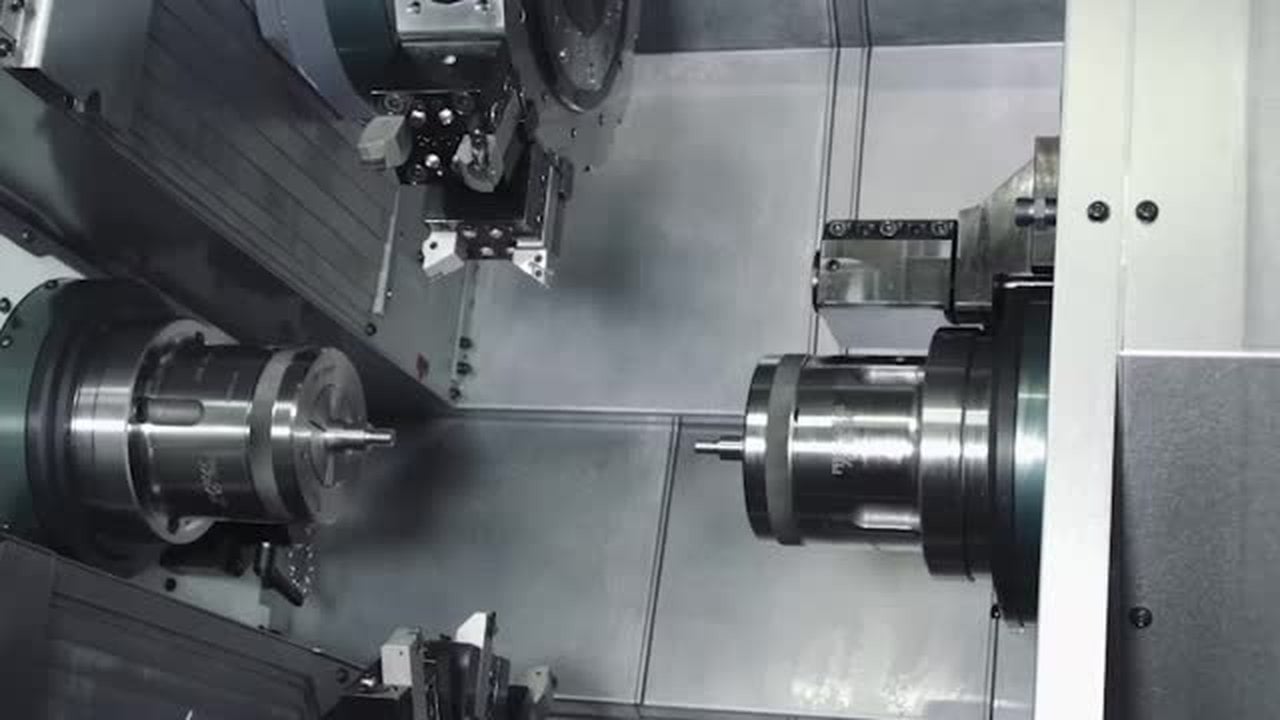

In a groundbreaking development for the manufacturing industry, CMZ has introduced an innovative feature that allows up to four tools to machine simultaneously. This functionality, named superimpose machining, is designed to enhance efficiency and precision in the manufacturing process by enabling double balance cutting.

Superimpose machining operates by combining movements from the master turret and the subspindle. This allows two tool trajectories to be machined simultaneously using the same turret station. For optimal results, one turret and the subspindle are programmed with the superimpose function while a second turret follows a single trajectory. A fourth tool benefits from the subspindle’s movement without needing its own ISO code.

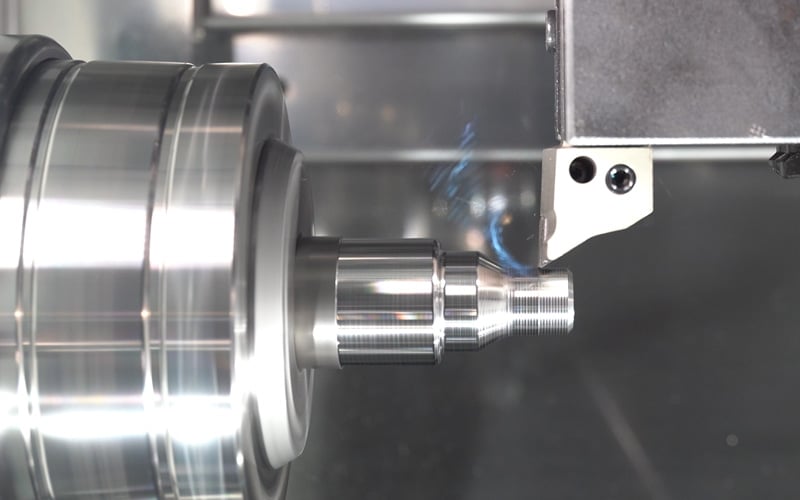

The method is especially recommended for roughing processes of symmetrical parts. However, it is not advisable for finished parts due to its specific operational strengths. To assist users, CMZ has developed user-friendly macros that simplify the programming of this advanced functionality. Tool and work offsets are transferred to the slave path to ensure seamless combined machining movements.

CMZ is committed to providing exceptional support for its customers, encouraging those interested in implementing superimpose machining to reach out for guidance. This innovation exemplifies CMZ’s dedication to pushing the boundaries of CNC technology and enhancing productivity in the manufacturing sector.

View more news from CMZ