Another SMEC SL 2000BM has been delivered to the Midlands, enhancing the region’s manufacturing capabilities. The SL 2000BM, a robust horizontal CNC turning center from Samsung Machine Engineering Company (SMEC), is renowned for its precision and durability. Designed for heavy-duty machining, it features a rigid box guideway and a 45-degree slant bed, minimizing vibration and thermal deformation.

The machine is equipped with an 8-inch chuck, capable of handling a maximum turning diameter of 360 mm and a turning length of 520 mm. It boasts an A2-6 spindle nose with a bar capacity of 68 mm, and a maximum spindle speed of 4,500 RPM.

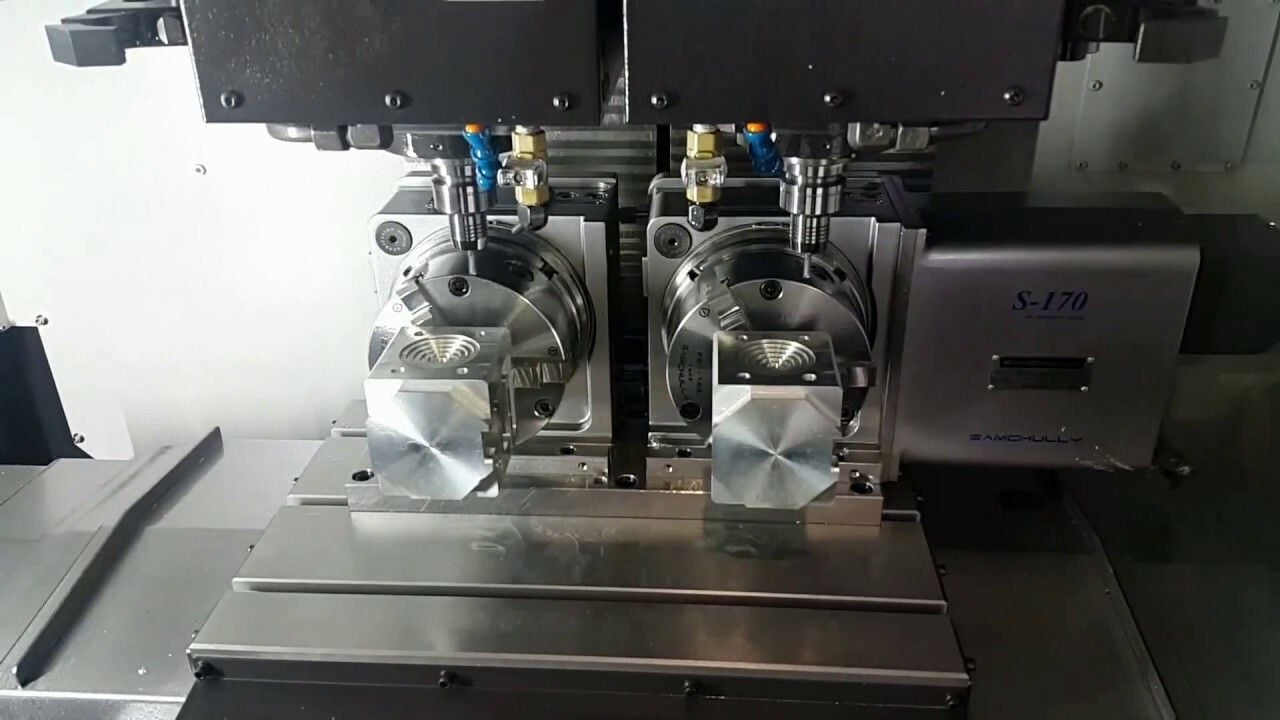

Known for its milling and drilling capabilities, the “BM” variant employs a 12-station turret, which can optionally be expanded to 24 stations, featuring BMT55 tooling and live tooling speed of up to 5,000 RPM. This configuration is powered by a 15/18.5 kW spindle motor, facilitating extensive operations with efficiency.

On the travel front, the SL 2000BM offers X-axis travel of 215 mm and Z-axis travel of 560 mm, supported by rapid traverse rates of 24 m/min for the X-axis and 30 m/min for the Z-axis. High-rigidity box ways enhance stability, ensuring effective handling of heavy-duty cutting tasks.

Thermal management is optimized with a headstock designed to minimize expansion, safeguarding precision over long operational periods. Control options for the machine typically include either Fanuc 0i-TF or Siemens 828D, providing versatility for various industrial applications.

The SL 2000BM is increasingly favored in the automotive, aerospace, and medical sectors for its ability to perform complex turning and milling operations. This addition in the Midlands underscores the region’s commitment to advancing its manufacturing infrastructure.

View more news from Dugard