12 May 2024

SPINNER TC 600 with Automation

Our TC600 is a performance universal lathe with This machine has the benefit of coming equipped with an automation solutions

View Product

Discover the latest special offers and featured products from leading manufacturers and suppliers.

Your roundup of current machine tool and product promotions and industry offers.

11 February 2026

DMK4-2A-A by balance-systems Semi-automatic balancing machine Features Semi-automatic balancing machine, specifically developed for balancing rotors for asynchronous motors and for brushless motors and similar rotating parts, in a completely automatic way on two planes (dynamic). The unbalance is corrected by removing material as an outcome of axial drilling. It is composed of: one measuring unit, two drilling units (one for each balancing plane) and a rotary table with pneumatic pliers for parts manipulation (from measuring unit to drilling units and vice versa). Operator interface by industrial PC. High level of flexibility and quick changeover. Advantages Automatic set-up High level

View Product

11 February 2026

DMK3 by balance-systems Semi-automatic balancing machine Features Semi-automatic balancing machine for small rotors weighing between 0.05 kg to 0.5 kg (0.11 and 1.10 lb). The material removal is carried out in a completely automatic way on two planes (dynamic). The unbalance is corrected by removing material on the lateral rings as an outcome of radial drilling. Manual loading/unloading. Advantages High measuring precision High balancing precision. User friendly. Quick and precise changeover by preset mechanical stops. Technology information Minimum rotor weight: 0.05 kg (0,11 lb) Maximum rotor weight: 0.5 kg (1,10 lb) Rotor OD: 8-40 mm (0,31-1,57 in) Controlled by:

View Product

11 February 2026

DC12MT by axile The DC12MT is the most robust VMC in AXILE’s arsenal, perfectly suited for handling larger, lengthy workpieces. With a 1200 mm diameter built-in table and 2.5 tonnes maximum weight capacity, the DC12MT is able to accommodate large and heavy 5ax components, while the 2,200 x 1,200 mm machine bed will take on board long and complex parts common in the aerospace, power generation, and die and mould industries. Its double-column bridge construction allows for greater rigidity, as well as greater control over thermal deformation. As a result, the DC12MT is capable of deep cuts and complex contouring while

View Product

11 February 2026

DC12i by axile The DC12i is the most robust VMC in AXILE’s arsenal, perfectly suited for handling larger, lengthy workpieces. With a 1200 mm diameter built-in table and 2.5 tonnes maximum weight capacity, the DC12i is able to accommodate large and heavy 5ax components, while the 2,200 x 1,200 mm machine bed will take on board long and complex parts common in the aerospace, power generation, and die and mould industries. Its double-column bridge construction allows for greater rigidity, as well as greater control over thermal deformation. As a result, the DC12i is capable of deep cuts and complex contouring while

View Product

11 February 2026

DC12iMT by axile The DC12iMT is the most robust VMC in AXILE’s arsenal, perfectly suited for handling larger, lengthy workpieces. With a 1200 mm diameter built-in table and 2.5 tonnes maximum weight capacity, the DC12iMT is able to accommodate large and heavy 5ax components, while the 2,200 x 1,200 mm machine bed will take on board long and complex parts common in the aerospace, power generation, and die and mould industries. Its double-column bridge construction allows for greater rigidity, as well as greater control over thermal deformation. As a result, the DC12iMT is capable of deep cuts and complex contouring while

View Product

11 February 2026

DC12 by axile The DC12 is the most robust VMC in AXILE’s arsenal, perfectly suited for handling larger, lengthy workpieces. With a 1200 mm diameter built-in table and 2.5 tonnes maximum weight capacity, the DC12 is able to accommodate large and heavy 5ax components, while the 2,200 x 1,200 mm machine bed will take on board long and complex parts common in the aerospace, power generation, and die and mould industries. Its double-column bridge construction allows for greater rigidity, as well as greater control over thermal deformation. As a result, the DC12 is capable of deep cuts and complex contouring while

View Product

11 February 2026

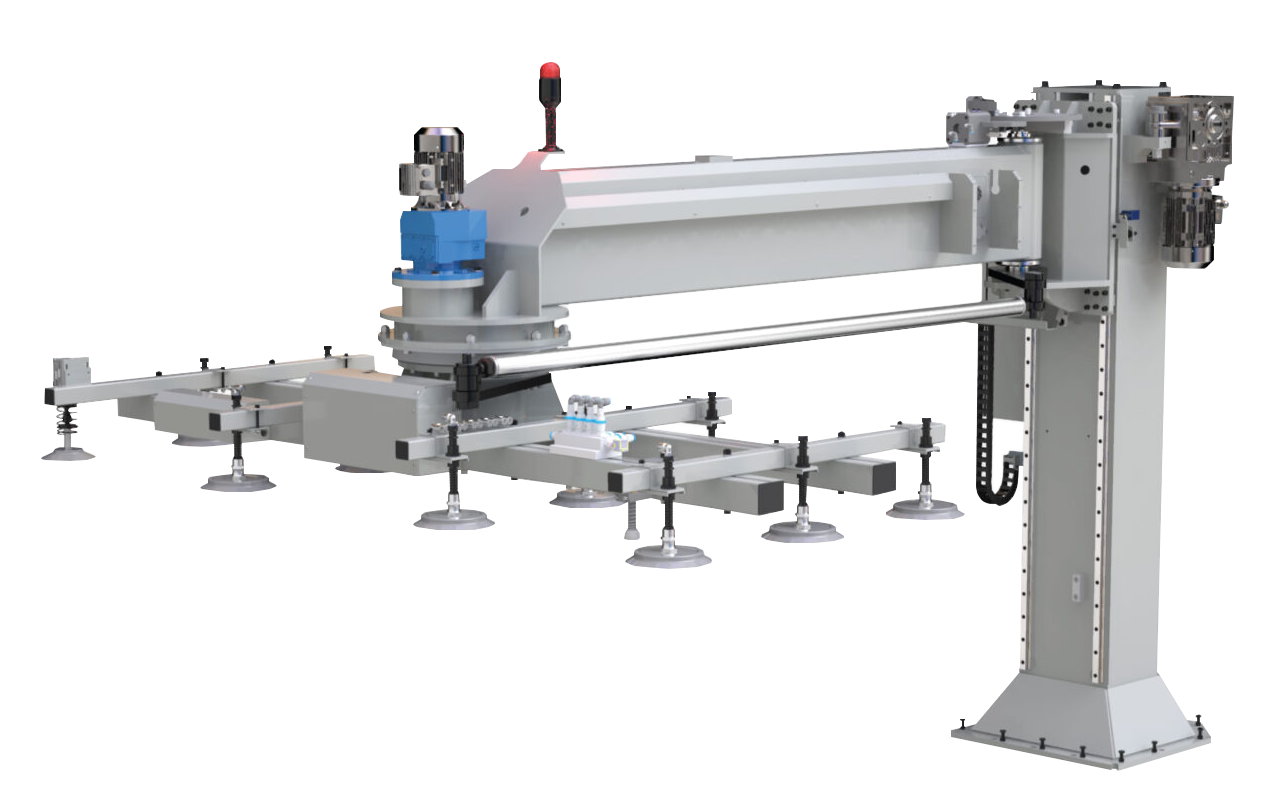

D-Loader Machine by durma Loading-unloading machines help to transport and load sheets. The main task of the system is to take the unprocessed sheets from the ground and load them onto the shuttle table. Durma D-Loader is a system specially designed to take the sheets from the ground and transport them to the required machine tables. D-Loader is very simple and easy to use. In addition to the automatic loading option, the D-Loader is also available for manual use under operator control. This machine is frequently used in laser cutting machines. The lifting system takes the plate from the ground

View Product

11 February 2026

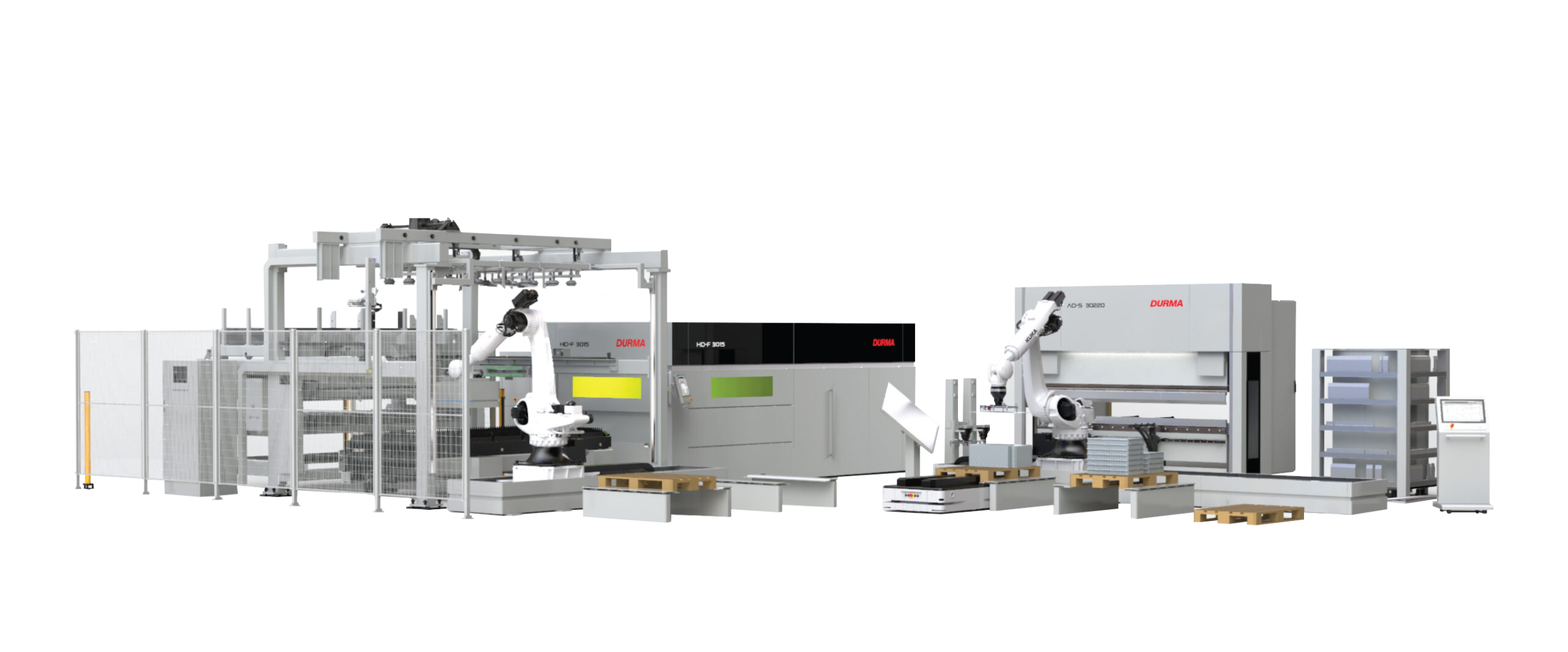

D-Line System by durma D-Line is a line system where two or more metal forming machines work in integration with automation systems. It provides efficient production thanks to high repeatability, high serial production and minimum error. D-Line is designed according to your needs by choosing machine automation systems in the most appropriate way for your production. D-Line, is a line system that consists of: Sheet stacking system, Punch – laser cutting machine, Sorting – sorting unit, Bending Center The Sheets are loaded into the system as sheets and finally bent panels come out. Its advantages are speed and efficiency. D-line

View Product

11 February 2026

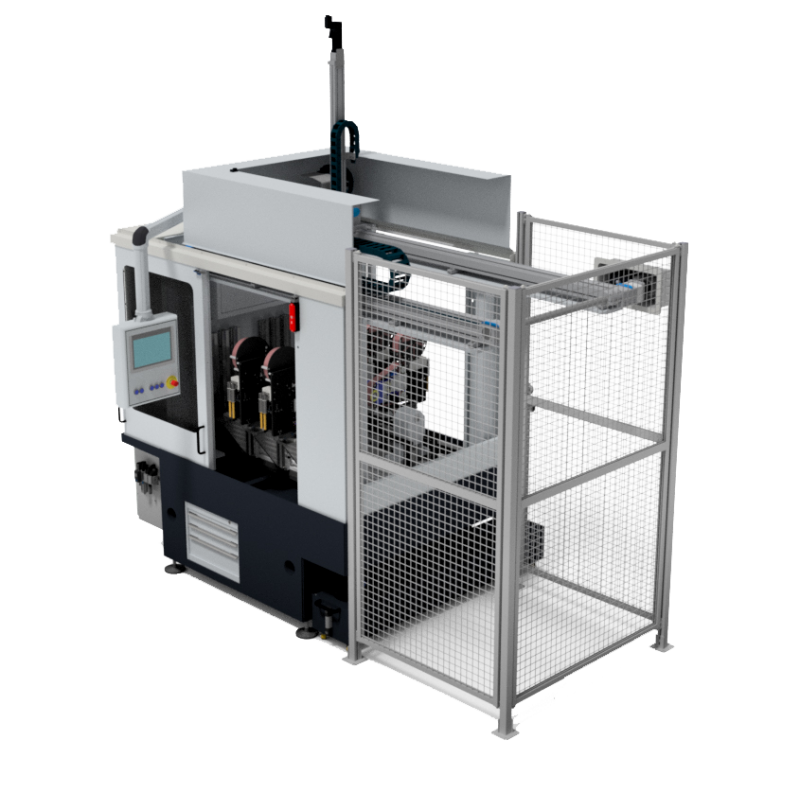

BVK4-5-3R by balance-systems Semi-automatic balancing machine Features Semi-automatic balancing machine, specifically developed for balancing rotors for brushless motors and similar rotating parts, in a completely automatic way on two planes (dynamic). The unbalance is automatically corrected by removing material as an outcome of radial milling. Parts manipulation performed by the operator. Operator interface by industrial PC. High level of flexibility and quick changeover. Advantages Automatic set-up High level of flexibility High level of repeatability and precision of the unbalance measuring Diagnostic and preventive maintenance program Quick changeover High level of reliability User friendly Technology information Max rotor weight: 3

View Product

11 February 2026

Cube Evo by thielenhaus Tape finish for shafts with the Thielenhaus CUBE. Superfinishing is particularly straightforward with the Cube due to its modular construction and touchscreen software. The Cube Evo is characterized by continuous programmability. In addition, the positions of the finishers can be approached extremely precisely. All processing parameters can be saved and retrieved quickly. The Cube Evo offers integrated and programmable handling via controller as well as a fast workpiece change. Technology information Loading/unloading manually or fully automatic Plunge-cut machining Tool width corresponds to seat width Detergent trolley with filter cartridge 5 μm Pneumatic min. 5 bar View

View Product

11 February 2026

BVK7-5-3A by balance-systems Automatic balancing machine for HVAC armatures Features Fully automatic balancing machine, specifically developed for balancing rotors of brushless motors and similar rotating parts, in a completely automatic way, on two planes (dynamic). It is composed of: a measuring unit and a milling unit for left and right planes. The parts manipulation is performed by an embedded anthropomorphic robot equipped with double gripper. The unbalances are automatically corrected by removing material by radial milling on the outer diameter of the rotor. It can be implemented in any type of production lines (pallet, step, by loop, etc.). High level

View Product

11 February 2026

BVK4-50-3A by balance-systems Automatic balancing machine Features Vertical automatic balancing machine, specifically developed for the balancing of assembled clutches on one plane (static). The unbalance is automatically corrected by axial milling and/or radial drilling. The milling unit is controlled by three axis and the correction is carried out by axis interpolation. It is composed of; measuring unit, axial milling with three controlled axis and an axial drilling unit (option). Parts loading is performed by an operator, while parts unloading is automatically performed by a controlled pick and place with an expandable gripper. High level of flexibility and quick production changeover.

View Product

Whether it’s new machinery, limited-time discounts, or special bundles, MTDCNC helps amplify your promotions through trusted industry coverage and multi-channel exposure. u2028Get your products seen by the engineers and decision-makers that matter most.

Featured Suppliers

Sign up to receive the latest videos, insights, and exclusive content from the world of manufacturing