Kitagawa has introduced the RKT500 and RKT600 rotary tables, designed specifically for small vertical machining centres (VMCs) demanding high precision, speed, and heavy load capacity. These rotary tables aim to enhance machining performance for complex tasks across various industries.

The RKT series features a Roller Gear Cam Mechanism, which provides zero-backlash, high efficiency, and rapid indexing speeds for seamless operations. This ensures smooth and precise cutting, crucial for industries such as aerospace and automotive manufacturing where intricate components are common.

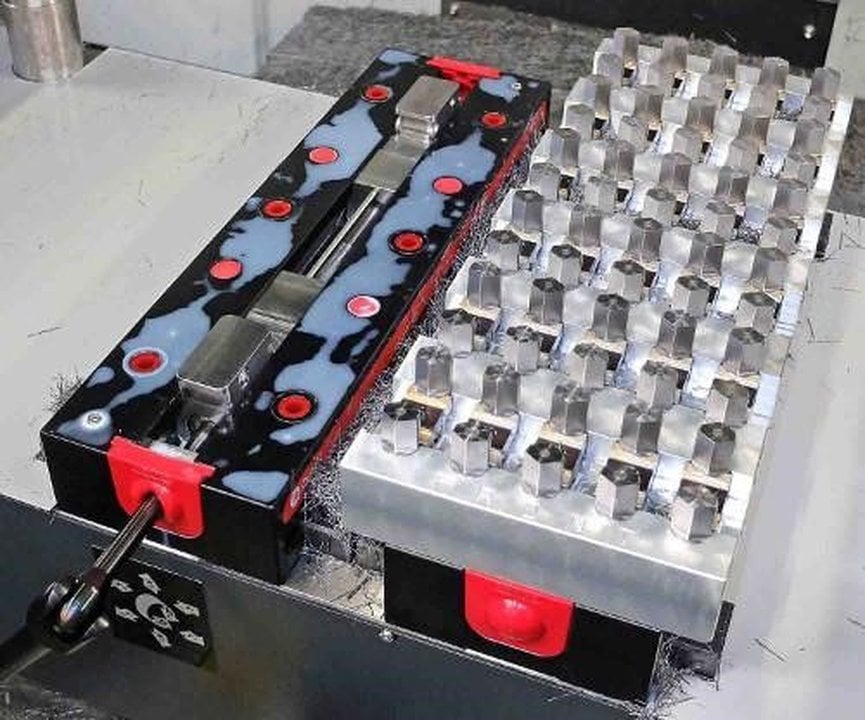

Both models boast impressive load capacities, supporting workpieces up to 600mm in diameter and 320mm high. The compact design fits comfortably on a No. 30 taper spindle machine, combining robustness with versatility.

The RKT500 and RKT600 are equipped with advanced hydraulic and pneumatic services, offering 7 ports on the RKT500 and 11 on the RKT600. This feature allows for flexible and automated workholding solutions, streamlining the manufacturing process.

Precision engineering is at the core of these rotary tables, with a repeatability of +/- 2 arc seconds and clamping torques reaching up to 740 N.m on the tilting axis. Kitagawa’s patented Multi-Plate Braking Technology provides enhanced stability and reliability, even under heavy loads, thus ensuring consistent performance.

These rotary tables are ideal for small VMCs, offering the benefits of 5-axis machining without the need for larger, more costly equipment. They promise to increase efficiency, accuracy, and flexibility, making them an ideal upgrade for manufacturers looking to advance their machining capabilities.

Kitagawa continues to deliver innovative solutions in the manufacturing industry, providing tools that meet the evolving demands of precision engineering.

View more news from 1st Machine Tool Accessories