Liebherr LGP 2000 Platform Advances Precision Grinding for Large Gear and Shaft Applications!

Liebherr Gear and Automation Technologies Inc. has introduced the LGP 2000 machine platform, a high-performance solution designed to enhance the profile grinding of large workpieces with diameters of up to 2,000 mm. The platform is engineered to meet the demanding requirements of manufacturers producing large gears and shafts for sectors such as mechanical engineering, marine propulsion, construction machinery, and wind power, where component size, accuracy, and surface quality are critical.

At the heart of the LGP 2000 platform is a high-precision, hydrostatically mounted table driven by a wear-free direct drive system. This design delivers smooth, backlash-free motion and long-term accuracy, even under heavy loads. The hydrostatic mounting minimizes friction and wear, making the system particularly well suited for continuous operation and large, high-value workpieces where repeatability and stability are essential.

Depending on the configuration, the platform uses flat or roller linear guides, selected to balance damping and precision across different machining stages. High damping characteristics support stable gear cutting, while maximum positioning accuracy is maintained during grinding and in-machine gear testing. Two main stand variants, offering strokes of 1,500 mm and 2,000 mm, enable efficient machining of long shafts with multiple gear teeth, expanding the range of components that can be processed on a single platform.

The LGP 2000 is designed with flexibility and productivity in mind. The machine platform supports automation solutions such as pallet changers and ring loaders, allowing manufacturers to integrate the system into automated production lines and reduce non-productive handling time. This makes the platform suitable not only for high-volume production but also for mixed or medium-batch environments where efficient changeover and automation are increasingly important.

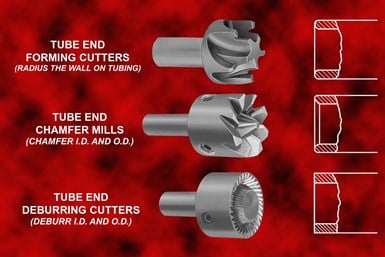

In addition to grinding, the platform offers advanced gear cutting capabilities. An optional chamfering device with a conventional end mill can be mounted directly on the cutter head, enabling cost-effective chamfering even in small batch sizes. For internal gear machining, an integrated chip removal system eliminates the need for separate chip channels in the factory floor, reducing infrastructure costs and simplifying installation. The gear cutting machines support both dry and wet machining, giving manufacturers flexibility to optimize processes based on material and application requirements.

For grinding operations, the LGP platform offers multiple grinding head configurations tailored to large gear profile grinding. A notable feature is the ability to use two grinding wheels sequentially without a tool change. This allows different tool specifications to be applied within a single cycle—either to shorten overall grinding time or to achieve higher surface quality in finishing operations, improving productivity without compromising precision.

The platform supports both high-speed grinding and creep-feed grinding, covering a wide range of process strategies. Single- and double-sided topological profile grinding can be performed, and with an optional swiveling internal grinding arm, internal grinding operations are also possible. These capabilities are enabled by Liebherr’s modern LHGearTec technology, which supports advanced grinding strategies for complex gear geometries.

To maintain grinding accuracy, the LGP 2000 can be equipped with either a conventional double dresser or an advanced double dresser that allows simultaneous dressing of both grinding wheel flanks. This reduces dressing time, improves consistency, and helps maintain stable grinding conditions over long production runs.

Overall, the Liebherr LGP 2000 machine platform combines precision mechanics, flexible grinding and cutting capabilities, and automation readiness. It is designed to support manufacturers facing growing demand for large, high-precision gears and shafts, while delivering the productivity, surface quality, and process reliability required in heavy-duty industrial applications.