GibbsCAM 2026 Delivers Faster Toolpath Generation and Smarter CAM Workflows!

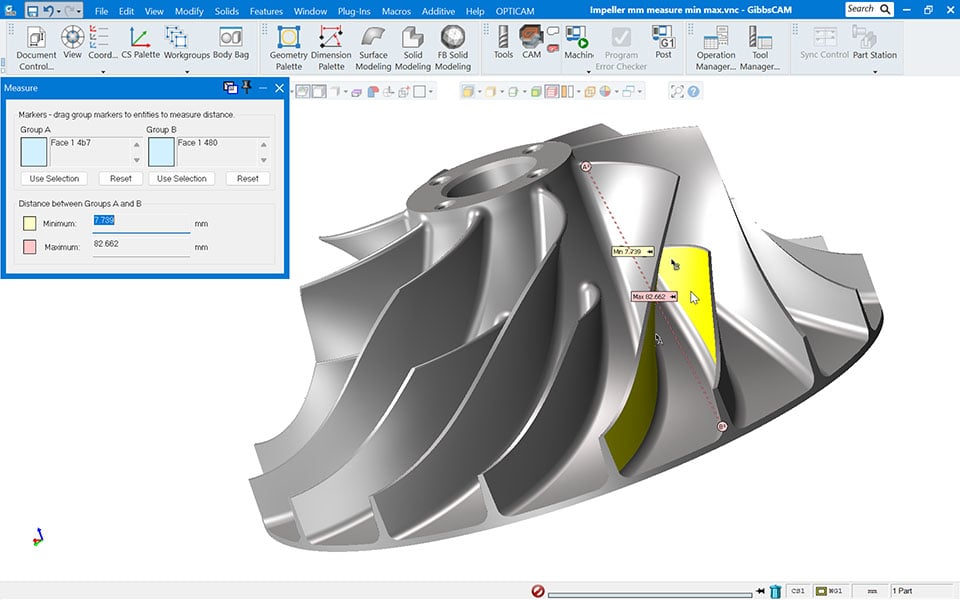

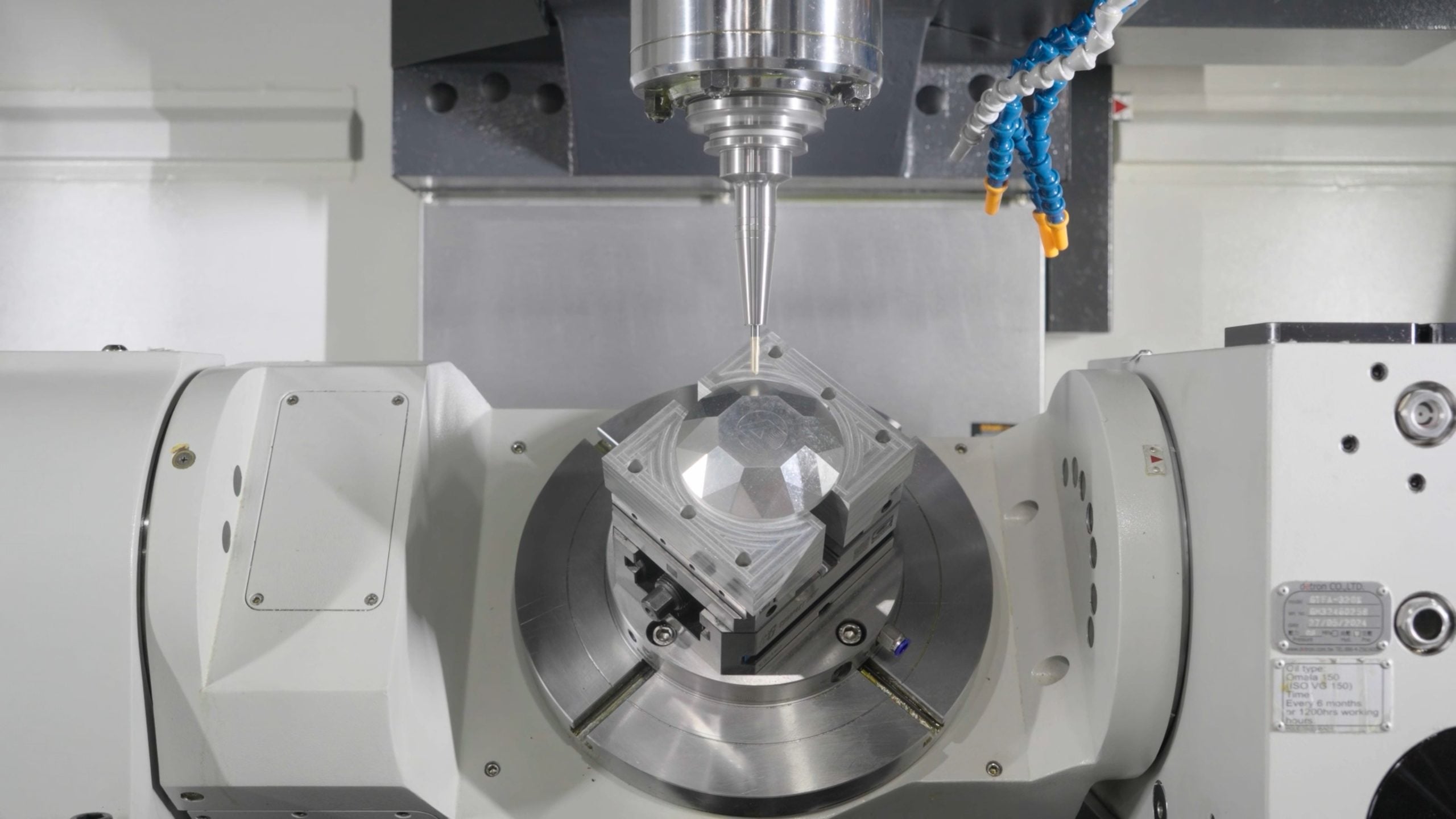

GibbsCAM has released GibbsCAM 2026, a major software update focused on significantly improving toolpath generation speed, surface quality, and overall programming efficiency. At the core of the release is a re-engineered Advanced 3D Machining Engine that reduces calculation time and minimizes the number of programming iterations required, helping manufacturers move from design to production faster and with greater confidence.

The new Advanced 3D Machining Engine has been designed to handle complex geometries more efficiently. By generating smoother and more predictable toolpaths, it improves surface finish quality while reducing the need for secondary finishing operations. Faster calculation times translate directly into shorter programming cycles, which is particularly valuable for shops handling high-mix, low-volume work or frequently changing part designs.

GibbsCAM 2026 also introduces a more intuitive and modernized user experience. Interface refinements make common workflows easier to navigate, helping both experienced programmers and newer users work more efficiently. A key addition is GibbsCAM Viewer, which allows teams across the organization—such as operators, supervisors, and quality engineers—to review and analyze CAM data without the risk of modifying toolpaths or NC code. Using the same familiar interface, users can visualize parts, inspect geometry, review toolpaths, and generate reports, improving communication while keeping programming data secure.

Turning operations see notable enhancements in this release, particularly with Variable-B Turning. The workflow has been made more interactive and intuitive, allowing programmers to define tool angles directly along the cutting path using control points. Smooth interpolation between these points provides precise control over complex turning operations, reducing setup effort and improving machining accuracy. For multi-sided turning tools, GibbsCAM now calculates material engagement more intelligently, enabling better use of insert geometry while maintaining safe cutting conditions. This results in improved material removal rates, consistent performance, and higher efficiency in advanced turning applications.

Tool management has also been strengthened with the introduction of the Tool Usage Reporter. This new capability provides detailed, operation-based visibility into how tools are used throughout a project. From a single interface, users can see every operation associated with a selected tool, highlight related toolpaths in the workspace, and quickly access or modify those operations. Complementing this is a redesigned, spreadsheet-style Tool List View with clearly labeled columns and filtering by tool group, making it easier to manage large tool libraries and complex jobs.

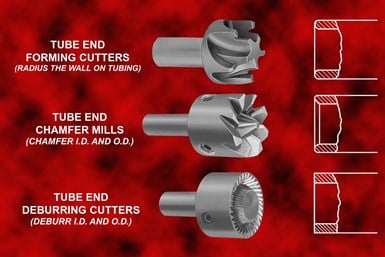

In multiaxis machining, GibbsCAM 2026 delivers refinements that reduce unnecessary machine motion and improve cycle efficiency. Enhanced AutoTilt functionality, now supporting bull-nose tools, provides greater flexibility in tool orientation. Improved tilting strategies help maintain optimal cutting angles while minimizing machine movements. Multiblade machining has also been upgraded with a new edge finishing strategy that delivers high-quality surfaces while protecting delicate leading edges. Expanded tool support and customizable feed rates for links, lead-ins, lead-outs, and edge extensions further reduce non-cutting time.

Overall, GibbsCAM 2026 focuses on practical, productivity-driven improvements. By combining faster toolpath generation, smarter turning and multiaxis strategies, better tool management, and secure company-wide data access, the update helps manufacturers improve programming efficiency, machining quality, and process reliability across a wide range of applications.