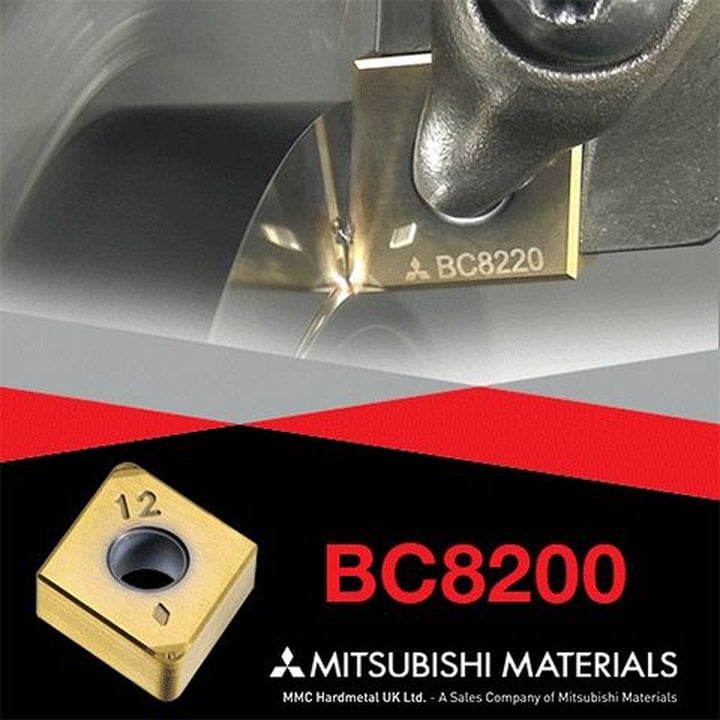

Mitsubishi Materials has launched the BC8200 Series, a cutting-edge solution designed for superior performance in the turning of hardened steels. This new series stands out with its advanced PVD coating and optimized substrate technology, providing exceptional wear and heat resistance, crucial elements for reliable machining.

The BC8200 Series caters to a broad spectrum of cutting conditions, ensuring consistent performance in both continuous and interrupted cutting operations. Mitsubishi Materials emphasizes the series’ ability to deliver the stability, durability, and extended tool life demanded by modern machining environments.

Specifically engineered with machining professionals in mind, the BC8200 Series addresses the growing needs for efficiency and precision in the metalworking industry. The advanced PVD coating offers protection and longevity, while the enhanced substrate technology supports precise and reliable cutting, even under high-stress conditions. This makes the BC8200 a versatile choice, adaptable to a variety of machining processes.

Mitsubishi Materials, known for its innovative solutions in manufacturing technology, has reinforced its position in the industry with this launch. The company’s commitment to developing high-quality products is evident in the BC8200 Series, aiming to meet the evolving demands of industries requiring efficient and robust machining solutions.

Professionals in the sector can now look forward to enhanced productivity and reliability, backed by Mitsubishi’s reputation for excellence. The BC8200 Series promises to be an essential tool for those involved in the turning of hardened steels, providing an edge in a highly competitive market.

View more news from MMC Hardmetal UK Ltd