Boers & Co Precision Machining Improves Working Climate with 3nine Oil Mist Separators

Boers & Co Precision Machining in Schiedam, the Netherlands, has seen clear improvements in both its working environment and machining processes since adopting 3nine oil mist separators. After experiencing immediate benefits, the company made the decision to equip all new machines with 3nine units, creating a cleaner, more stable, and more efficient production environment.

The first 3nine oil mist separator was installed in Boers & Co’s workshop in 2015, and the impact was noticeable right away. According to Ronald Koot, CEO of Boers & Co, the working climate improved immediately, which in turn led to a more stable machining process. Since then, the company has worked closely with Glavitech, 3nine’s partner in the Benelux region, to ensure that every new machine is equipped with a 3nine unit.

“Since we started working with 3nine, the air quality has improved enormously,” says Ronald Koot, CEO of Boers & Co.

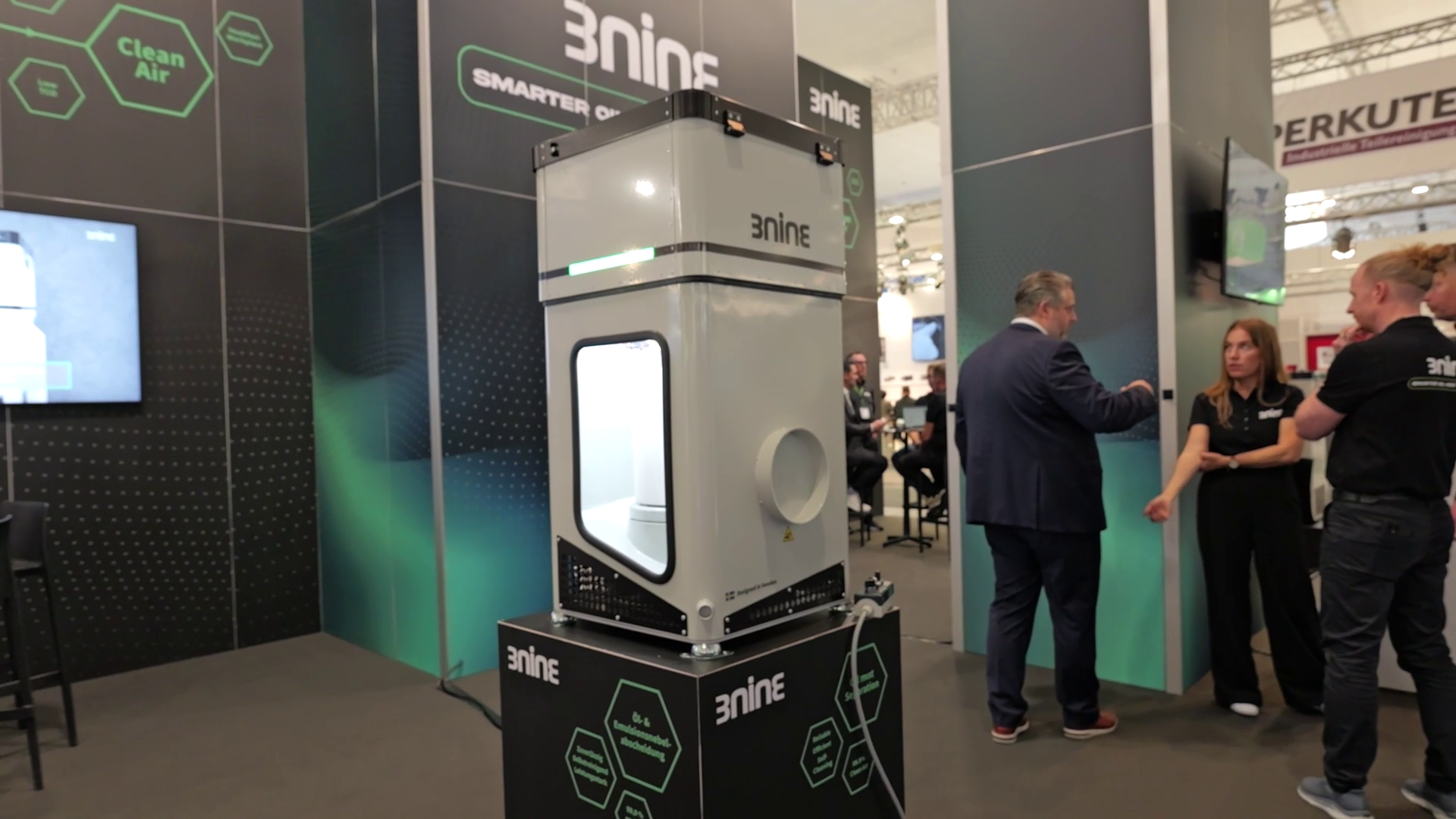

As a supplier of high-quality precision components, Boers & Co relies on advanced machining centers with high-speed spindles and high-pressure pumps to achieve optimal cooling and chip removal. These processes generate a fine mist of cooling lubricant particles, making efficient extraction essential. Traditional filter systems quickly became saturated and recirculated contaminated air. In contrast, 3nine’s separators effectively remove nearly 100% of particles, ensuring clean air and significantly improved working conditions.

The decision to equip new machines with 3nine separators is closely tied to Boers & Co’s commitment to employee well-being. The improved air quality contributes to a healthier work environment, even after periods of unmanned production. The company’s focus on automation also extends to internal logistics, ensuring parts are cleaned promptly to prevent staining and contamination. By maintaining cleaner air, the 3nine separators support better temperature control and dimensional stability, contributing to a more reliable machining process.

Beyond air quality improvements, the 3nine solution has delivered longer maintenance intervals and reduced consumption of cooling lubricants. The rotating disc stack separates particles before they reach the HEPA H13 filter, significantly extending filter life compared to traditional systems. This results in lower maintenance demands and long-term cost savings, further reinforcing the value of 3nine oil mist separators in Boers & Co’s production.