Cleaner Air, Less Maintenance: Why RZ Zampart Chooses 3nine for Sustainable Production

Cleaner air, lower maintenance, and a solution that simply works—these are the reasons RZ Zampart relies on 3nine in its pursuit of sustainable and efficient production.

Based in Karlstad, Sweden, RZ Zampart is part of the RZ Group, a network of 17 companies across central Sweden. In recent years, the company has experienced strong growth and is now a key supplier to demanding industries such as defense and automotive.

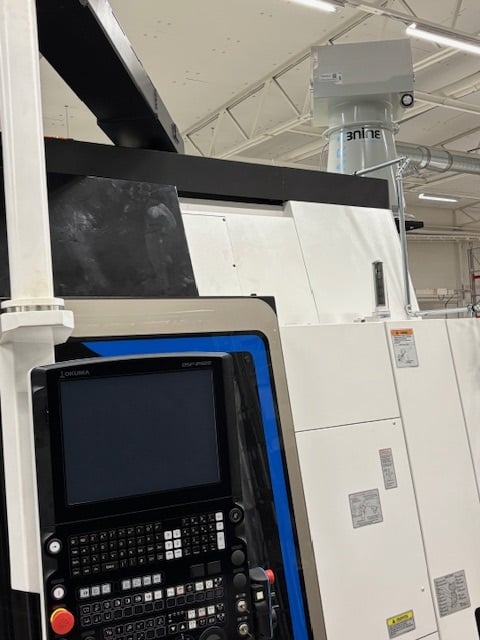

With approximately 60 CNC machines, 210 employees, and three-shift production running 24/7, reliability across every part of the operation is essential. At the same time, sustainability and a healthy work environment are top priorities. RZ Zampart is ISO 14001 certified, a signatory to the UN Global Compact, and has clearly defined goals for energy efficiency and reduced environmental impact. Air quality in the workshop is a critical part of that commitment.

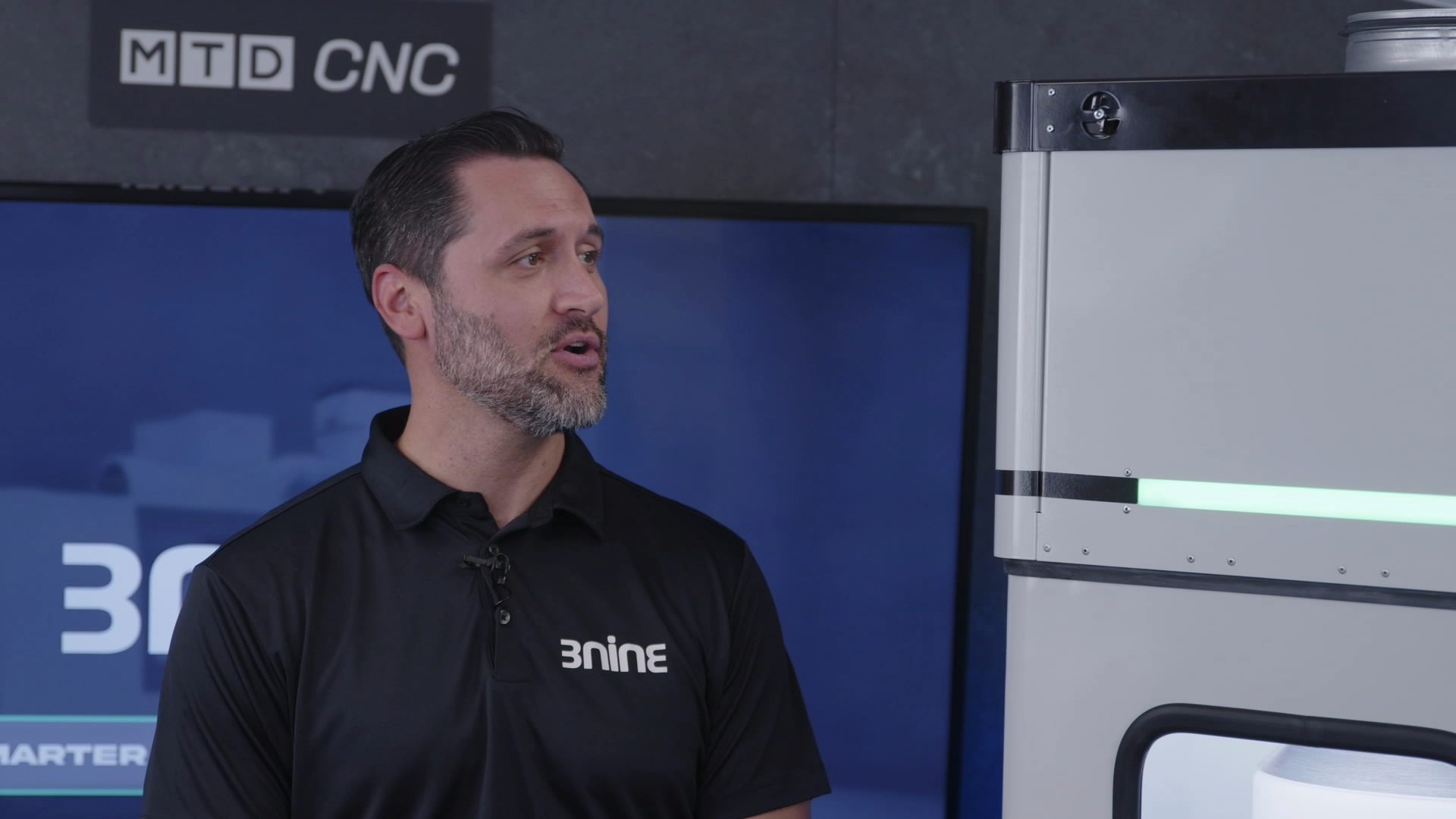

“We notice a big difference where we’ve installed a 3nine unit—the air is significantly better. And the machines require very little maintenance; they just keep running. It’s a very smooth solution,” says Daniel Stjernstrand, Project Manager at RZ Zampart.

The Challenge: Oil Mist Affecting People and Machines

In a high-intensity machining environment with extensive coolant use, oil mist is unavoidable. It impacts air quality, settles on surfaces, and can lead to health concerns as well as increased cleaning and maintenance. Even with traditional filter cabinets, oil mist often lingered in the workshop—especially when machine doors were opened.

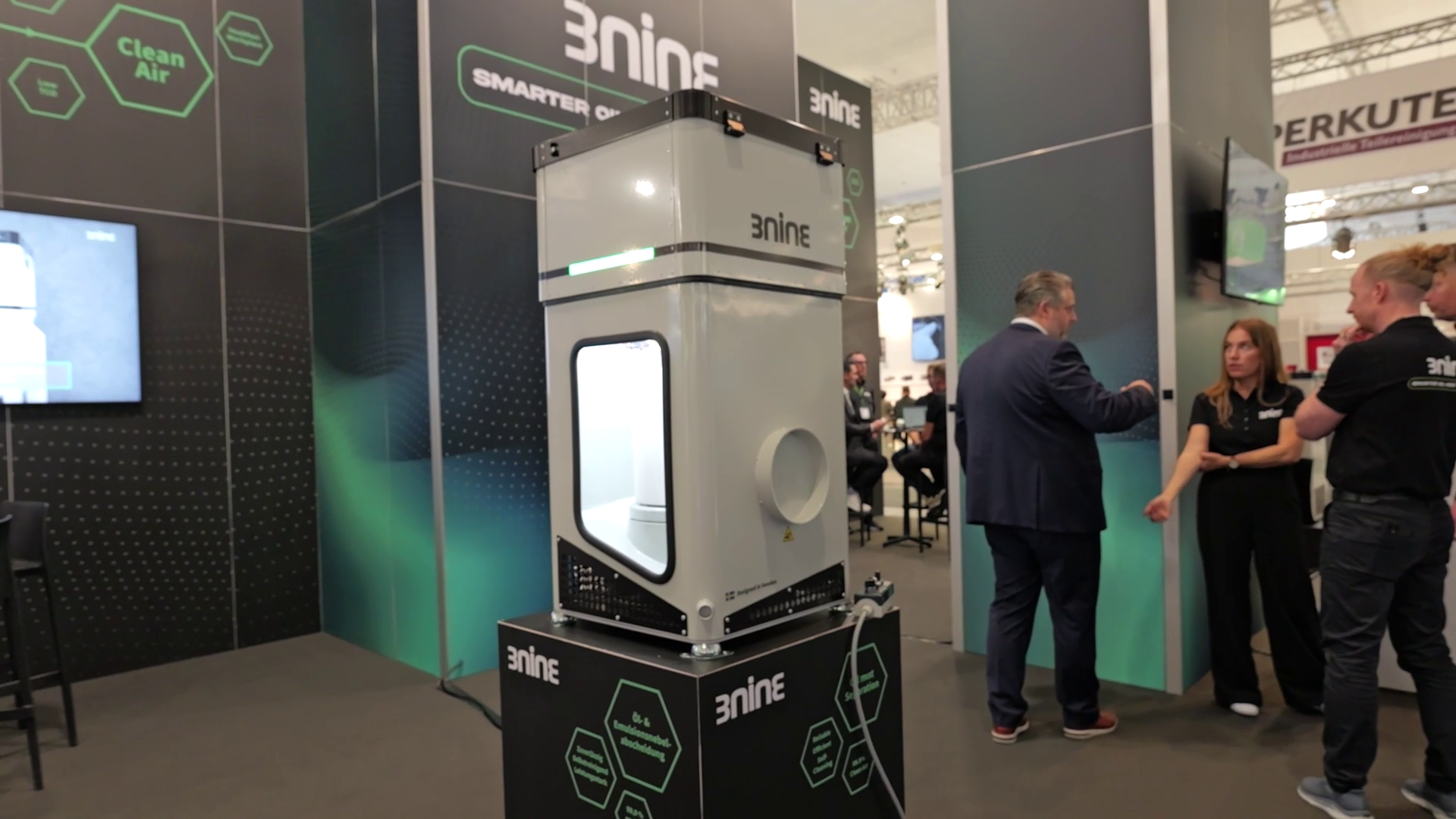

The Solution: Separation Instead of Filtration

Rather than collecting oil mist in filters, 3nine units separate liquid particles from the air. Using patented disc stack separation technology—originally developed for milk separation—the units remove up to 99.9% of particles down to 1 μm.

This results in clean air that can be safely returned directly to the workshop, while the separated coolant can be reused. With 3nine’s patented Clean In Place (CIP) technology, the rotor is cleaned automatically, ensuring consistent performance with minimal maintenance.

“We might replace the filter once a year—if that. The machines just keep going,” Daniel adds.

The Result: A Cleaner, Smarter, and More Sustainable Workshop

Today, around 15 of RZ Zampart’s machines are equipped with 3nine units, with more added continuously. The long-term goal is to equip all new machines with 3nine solutions and gradually replace older systems as they are phased out.

For RZ Zampart, the benefits are clear:

- Improved air quality directly at the machine

- Minimal maintenance requirements

- Smooth installation without disrupting production

- Lower lifecycle costs compared to traditional filter systems

Most importantly, the solution supports a healthier work environment—one where people can thrive and perform at their best, every day.