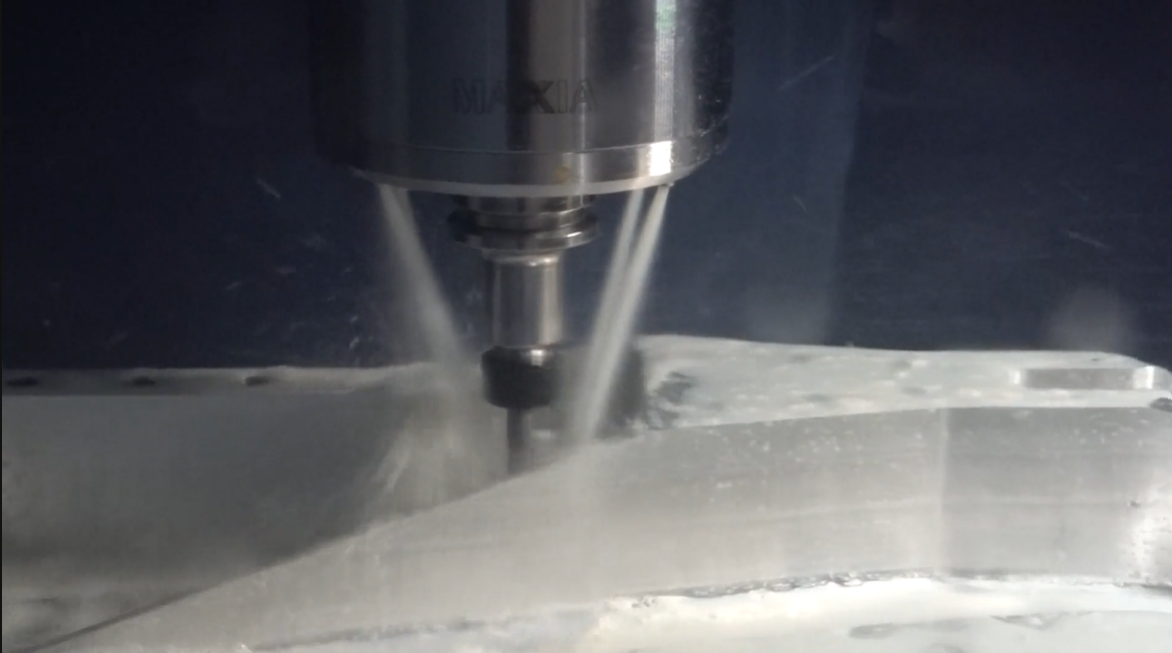

Matsuura Machinery USA, Inc. has unveiled its groundbreaking hybrid metal additive manufacturing technology, which combines selective laser sintering (SLS) with high-speed CNC milling. This innovative approach enables the creation of complex, high-precision metal parts with intricate internal features, such as conformal cooling channels, that were previously unattainable with traditional methods.

The integration of SLS and CNC milling in a single machine eliminates design limitations and enhances production efficiency for molds, aerospace, and medical components. By streamlining the manufacturing process, Matsuura’s technology allows for faster production times and reduced costs, setting a new standard in the industry for precision and complexity.

The hybrid machines are specifically engineered to meet the demands of manufacturers seeking to create intricate parts without compromising strength or accuracy. The ability to incorporate internal features directly into the design paves the way for innovative applications, particularly in industries that require highly specialized and intricate components.

Matsuura Machinery USA, Inc. continues to push the boundaries of manufacturing technology, ensuring their customers remain at the forefront of the industry. By merging two advanced manufacturing processes, the company reinforces its commitment to innovation and excellence in the production of complex metal parts.

For more information on how this technology can transform your manufacturing processes, visit the Matsuura website.

View more news from Matsuura Machinery USA, Inc.