HAINBUCH America Corporation is set to transform CNC machining as it focuses on efficiency and capacity. With a forward-looking approach to 2026, the company emphasizes the importance of reducing machine downtime to maximize productivity. They propose that the key to increased capacity lies in optimized setups using advanced workholding solutions.

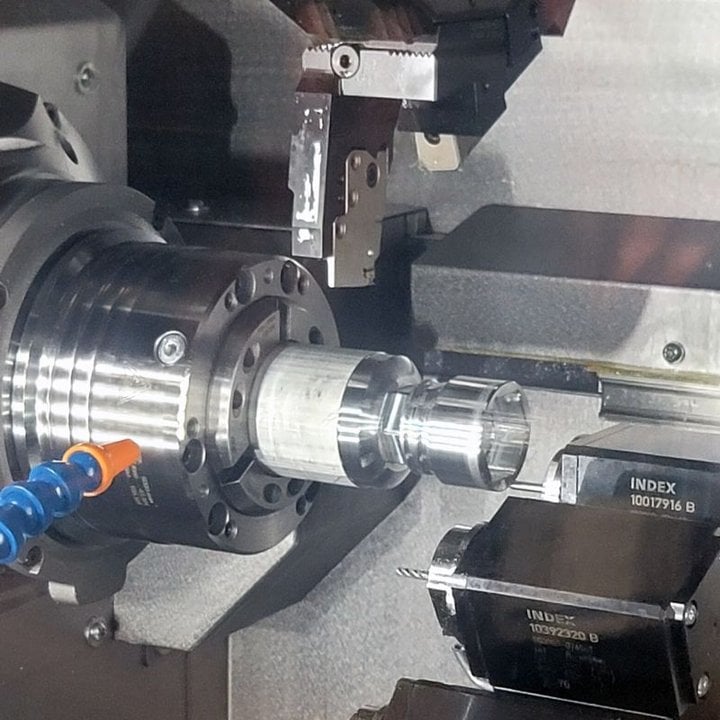

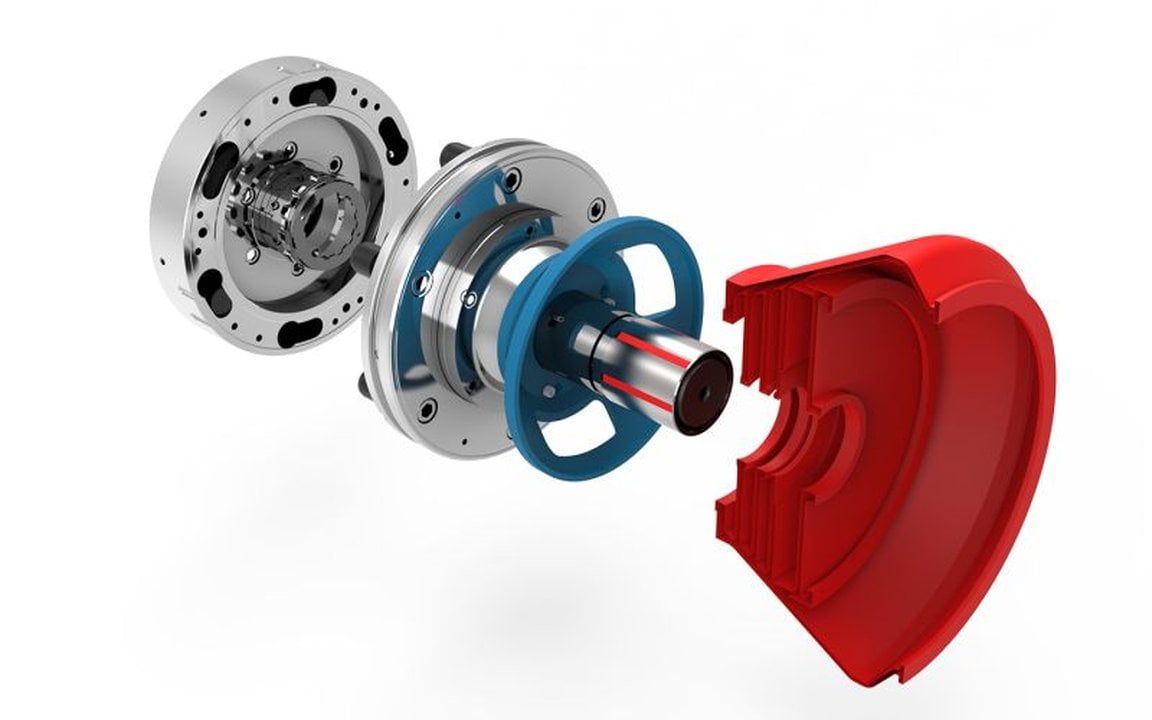

HAINBUCH’s latest offering promises significant enhancements in machine operations by replacing cumbersome traditional setups with a state-of-the-art modular system. This innovative solution is tailored to provide rapid changeovers, micron precision repeatability, and exceptional rigidity, ensuring that businesses can adapt swiftly to varying production demands.

The modular workholding approach allows for seamless transitions, reducing idle machine time and thus improving overall throughput. By focusing on high-precision components, HAINBUCH ensures that manufacturers can rely on consistent accuracy, critical for maintaining quality standards in high-demand industries.

This strategic development comes at a time when manufacturers are keenly looking for ways to streamline operations and maximize output. By minimizing the complexities associated with machine setups, HAINBUCH’s solutions offer a pathway for manufacturers to elevate their performance, aligning with future industry demands.

Established in North America, HAINBUCH has a reputable history of innovation in manufacturing solutions. Their ongoing commitment to enhancing CNC machining capabilities solidifies their position as a leader in the workholding sector, offering cutting-edge tools designed to meet the rigorous requirements of modern production environments.

View more news from HAINBUCH America Corporation