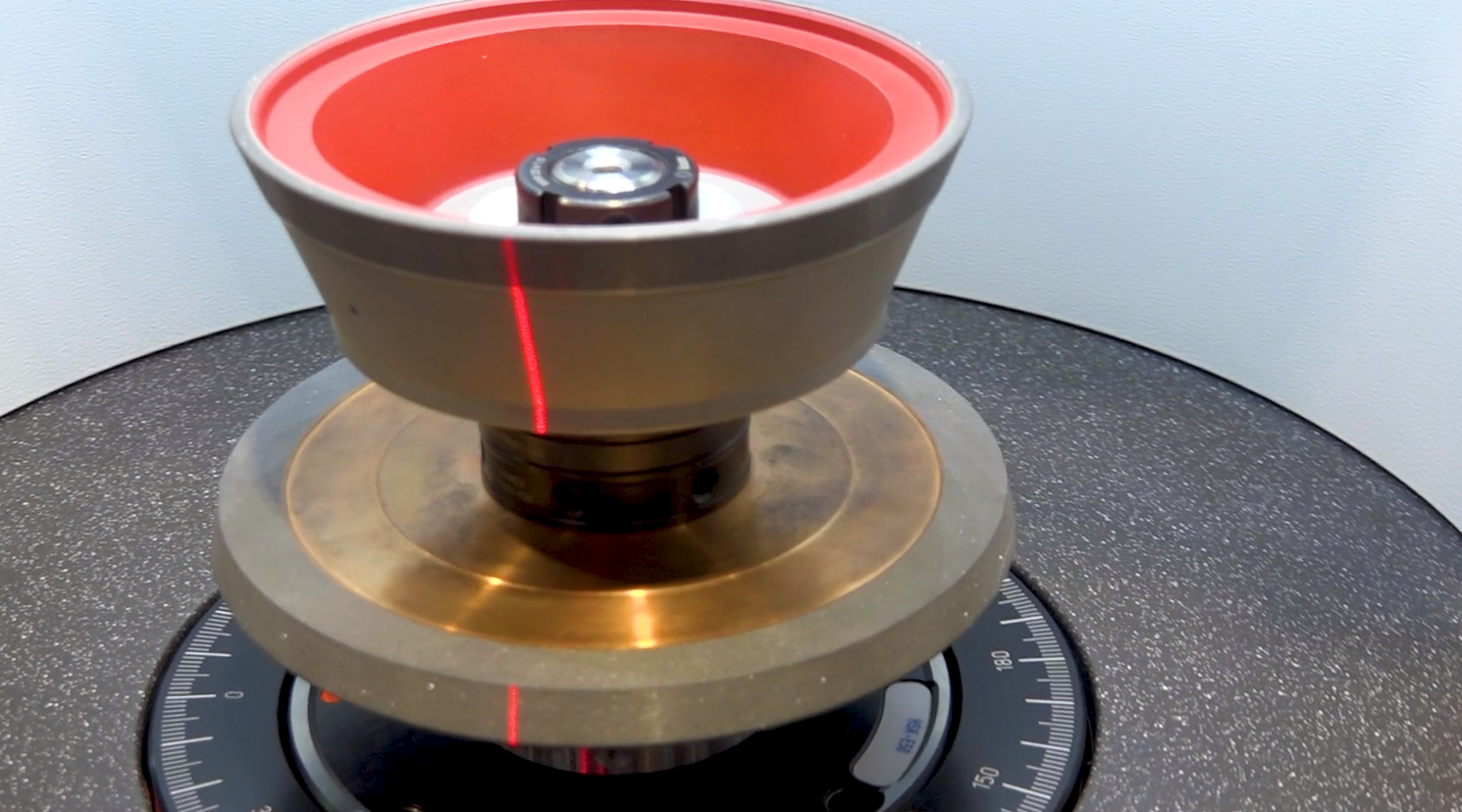

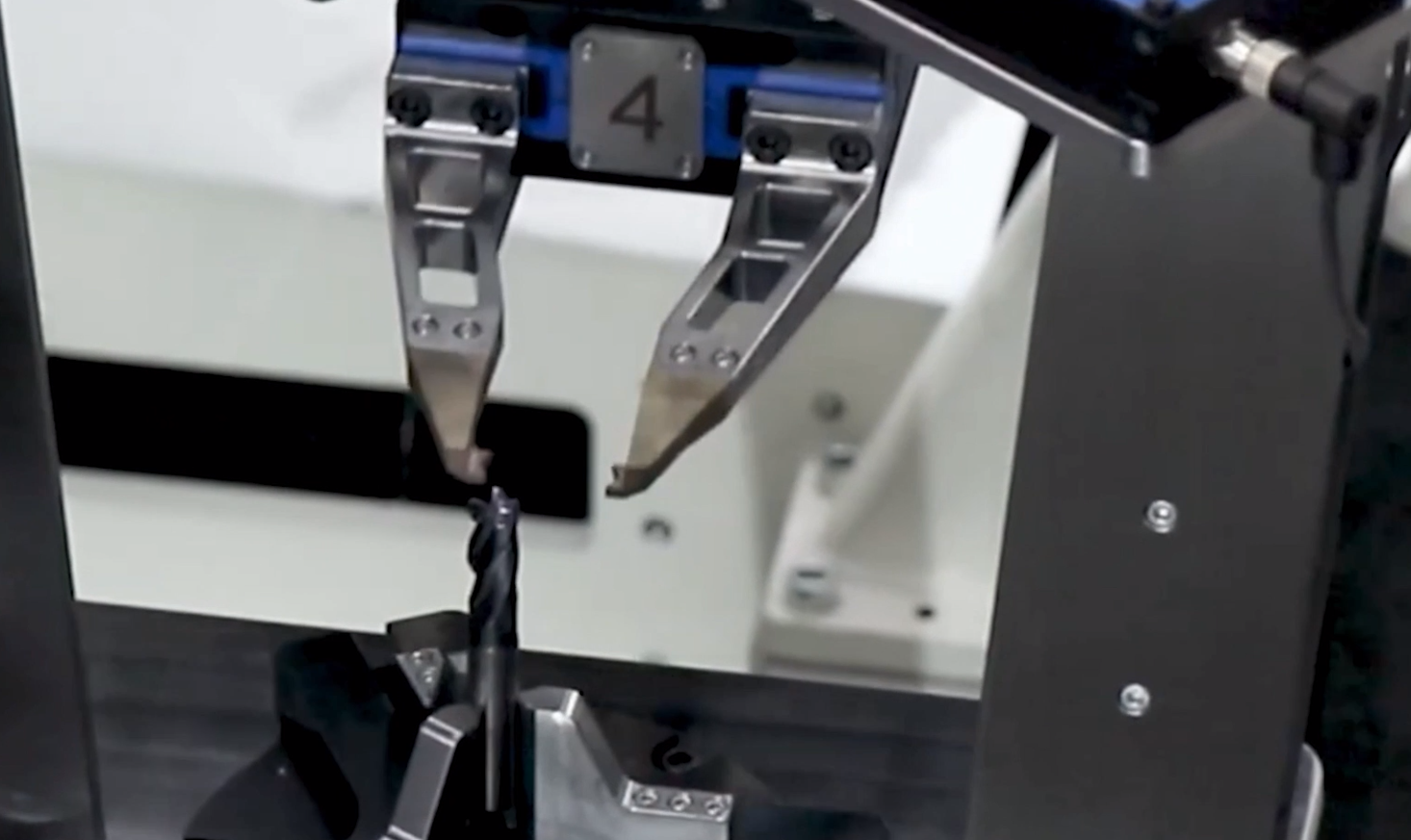

HAIMER, a leader in precision engineering, has announced the advancement of its Microset presetter machines to enhance manufacturing processes. These machines are designed to deliver accurate and repeatable tool measurements outside the machine environment. This innovation aims to significantly reduce setup times and minimize errors, ensuring reliable production from the first cut.

The Microset presetting machines represent a pivotal step in developing a more efficient and consistent toolroom. By allowing precise tool measurement, manufacturers can achieve high-quality outcomes, thus optimizing overall production efficiency. HAIMER’s focus on innovation reflects their commitment to advancing manufacturing practices, aligning with industry demands for precision and reliability.

At the core of this advancement is the emphasis on precision engineering. Accurate tool measurement is essential for reducing variability and ensuring consistency in production, positioning HAIMER’s Microset as an indispensable tool in modern manufacturing settings.

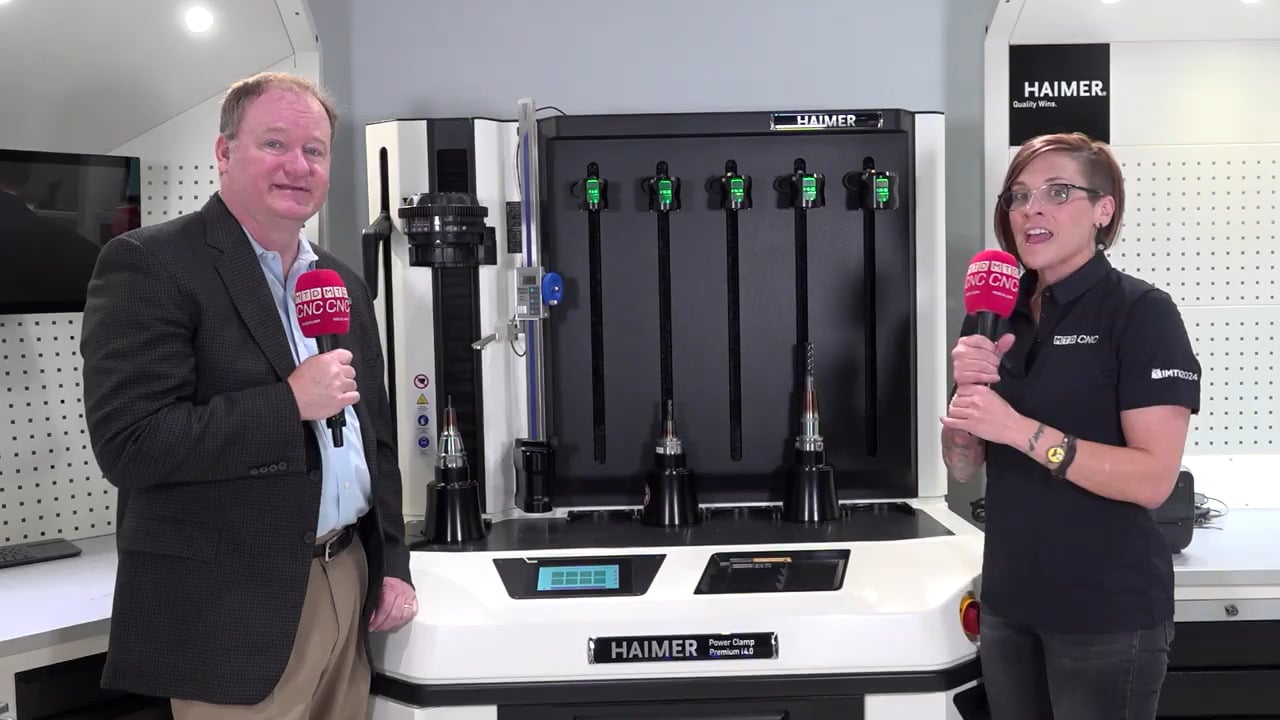

The introduction of these machines is expected to redefine toolroom operations, paving the way for future advancements in manufacturing precision and efficiency. HAIMER’s continuous efforts in technology advancement illustrate their role as a frontrunner in the field, supporting industries in achieving optimal performance standards.

HAIMER, globally recognized for its innovation in tool holding and balancing technology, continues to set industry benchmarks. The introduction of the Microset presetter machines underscores HAIMER’s commitment to enhancing toolroom capabilities and supporting manufacturers in achieving excellence.

View more news from HAIMER USA