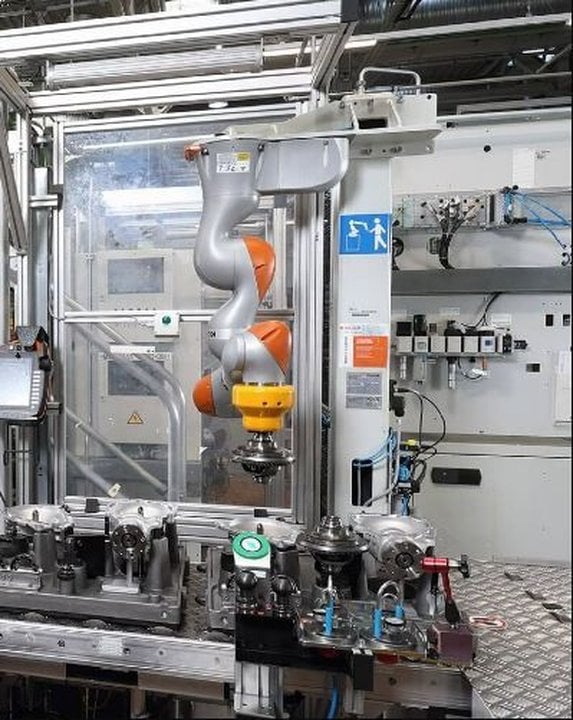

KUKA, a leader in automation technologies, is revolutionizing factory management with its new Smart Plant Service. This initiative emphasizes that automation doesn’t conclude with initial commissioning but instead flourishes through ongoing optimization. The focus is on maintaining high system availability and minimizing downtime.

The cornerstone of KUKA’s Smart Plant Service is its predictive maintenance approach. This strategy aims to identify potential issues before they lead to costly downtimes, thereby ensuring seamless production operations. The service also offers a robust RemoteService, allowing for swift troubleshooting, which enhances overall system reliability.

KUKA’s modular service contracts are tailored to meet specific needs, providing a range of solutions that are both adaptable and comprehensive. These contracts combine preventive maintenance, remote support, and digital services to ensure production lines remain not only automated but also future-proof and highly efficient.

Through these innovations, KUKA is not only providing superior technology but also a reliable partner in the manufacturing industry. By offering flexible and customized service packages, the company is catering to the evolving demands of the industrial sector, keeping it at the forefront of automation technology.

For those interested in learning more about these service contracts and how they can enhance production capabilities, further details are available on KUKA’s website.

View more news from KUKA