Heule Precision Tools Introduces Vex Tooling for One-Step Drilling and Chamfering!

Heule Precision Tools has introduced its Vex tooling system, a productivity-focused solution engineered to perform drilling and chamfering in a single operation. Designed for high-production and high-precision manufacturing environments, the Vex system helps manufacturers reduce cycle times, eliminate tool changes, and achieve consistent hole quality in demanding applications.

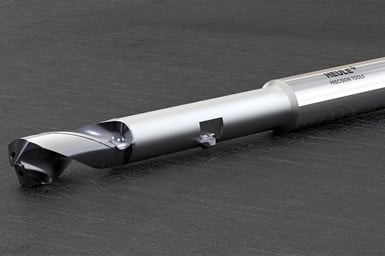

At the core of the Vex tooling concept is a solid carbide drill tip combined with Heule’s proprietary SNAP chamfering system. This integrated design allows through-holes to be drilled and chamfered in one continuous process, significantly improving efficiency compared with conventional multi-tool approaches. The tooling is available in diameters ranging from 5 to 17 mm, offering flexibility across a wide range of component sizes.

Regardless of diameter, the Vex drill tip features a convex cutting edge geometry that delivers stable drilling performance and produces short, well-controlled chips. This makes the tool particularly effective when machining long-chipping materials, where chip control is critical to maintaining surface quality and process reliability. The optimized geometry supports smooth cutting action and consistent results even in high-speed, high-volume production.

The Vex system is built around a specialized connecting interface that provides a robust and highly precise connection between the tool body, drill tip, and chamfer blade. This secure attachment ensures efficient power transmission, minimizes vibration, and contributes to improved dimensional accuracy and surface finish. As a result, the tooling is well suited for precision-critical industries such as automotive manufacturing, where repeatability and reliability are essential.

Typical applications include components such as brake discs, wheel hubs, tubes, and similar rotational or structural parts, where large volumes of through-holes must be produced with tight tolerances and clean chamfers. By eliminating the need for a secondary chamfering operation, Vex tooling reduces tool inventory, simplifies programming, and shortens overall machining time.

Chip management is further enhanced by a large chip channel that promotes efficient swarf evacuation. This improves process cleanliness and operator safety while reducing the risk of chip-related surface damage or machine downtime. Maintenance is also simplified: both the drill tip and chamfer blade can be replaced quickly without the need for presetting, helping minimize downtime during tool changes.

In addition, the replaceable drill tip can be re-ground and re-coated, extending usable tool life and lowering overall tooling costs. With its combination of productivity gains, precision performance, and cost efficiency, the Vex tooling system reflects Heule Precision Tools’ focus on delivering practical innovations for modern, high-output manufacturing environments.