Prima Power Expands 3D Laser Cutting Portfolio with Laser Next Core for Flexible Manufacturing!

Prima Power has expanded its 3D laser cutting portfolio with the introduction of the Laser Next Core, a compact and cost-effective solution designed to meet the needs of job shops and manufacturers operating in highly flexible production environments. The new system is aimed at companies that handle small to medium batch sizes, frequent product changeovers, and variable part geometries, where speed, adaptability, and fast return on investment are critical.

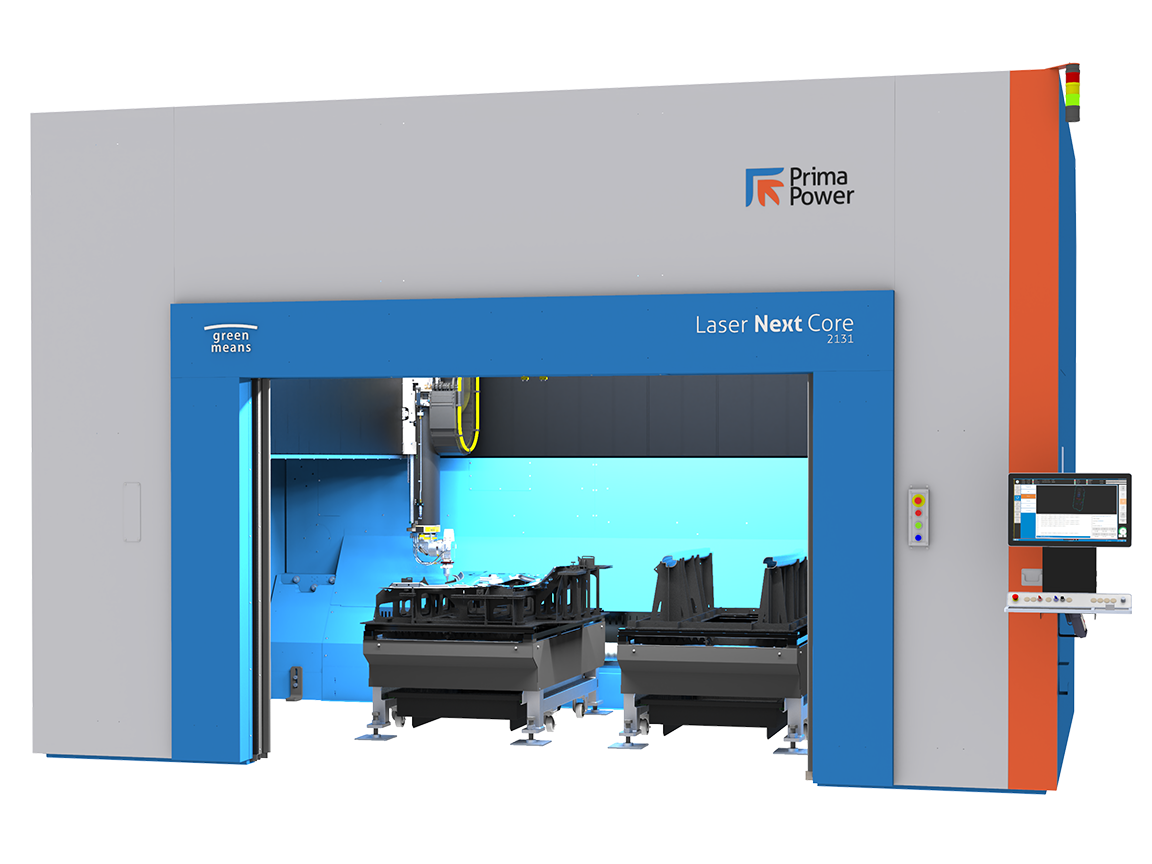

Laser Next Core has been engineered with a reduced footprint while still offering generous working capacity. With axis strokes of 3,160 × 2,100 × 750 mm, the system can process components of virtually any shape and size, supporting both 2D and 3D laser cutting operations. This versatility makes it well suited for manufacturers producing batches typically below 1,000 parts, where rapid setup and efficient transitions between jobs are essential to maintaining productivity and profitability.

A key focus of the Laser Next Core is achieving a low cost per part. Prima Power has optimized both fixed and operating costs by reducing labor intervention, minimizing maintenance requirements, and limiting gas and power consumption. Features such as safe-cutting nozzles help lower nitrogen usage by up to 30%, contributing to reduced operating expenses while supporting more sustainable production practices. Together, these elements enable manufacturers to achieve consistent part quality while keeping overall production costs under control.

Ease of use is another central aspect of the system’s design. Machine operation is simplified through one-click programming, an intuitive human-machine interface with a graphical teach panel, and automatic head-offset compensation via a local head axis. These features reduce the learning curve for operators and make advanced 3D laser cutting accessible even in shops without specialized programming resources. As a result, manufacturers can respond quickly to changing customer requirements without sacrificing accuracy or repeatability.

From a mechanical standpoint, the Laser Next Core integrates maintenance-free linear drives and direct motors that deliver high dynamics, precision, and long-term reliability. Dual-position, height-adjustable tables improve ergonomics and part handling flexibility, allowing operators to manage loading and unloading more efficiently. An optional welding head further extends the machine’s application range, enabling lap and butt welding operations in addition to cutting, which adds further value for customers seeking multifunctional capability from a single platform.

With the addition of the Laser Next Core, Prima Power’s 3D laser cutting lineup now spans four distinct machine categories. The Laser Next Core 2131 targets flexible production with low cost-per-part, while the Laser Next 2141 balances flexibility with higher productivity. The Laser Next 1530 and 2130 models are optimized for continuous, high-throughput environments, including automated material handling. At the top end of the range, the recently launched Giga Laser Next addresses large-scale, high-volume manufacturing with maximum productivity in a compact layout.

All Prima Power 3D laser machines, including the Laser Next Core, can be integrated into turnkey automated systems using the company’s in-house robotics integration platform. This modular approach allows manufacturers to combine cutting, part handling, loading and unloading, and quality inspection into a seamless production flow that can evolve as business needs change. Through this expansion, Prima Power continues to position its 3D laser solutions as adaptable, future-ready tools for modern manufacturing environments.