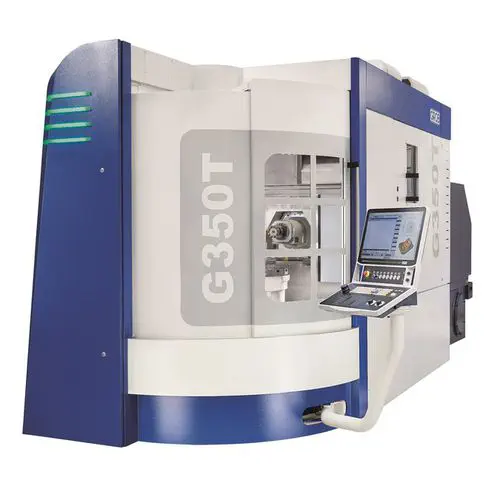

Grob G350T Mill-Turn Center Elevates Stability, Flexibility and Process Reliability for Smaller Part Production!

By Ashutosh Arora

Grob Systems Inc. has expanded its universal machining portfolio with the introduction of the G350T, a compact five-axis mill-turn center engineered to deliver exceptional stability, precision and maintainability for manufacturers working with smaller, complex components. Designed to handle a wide range of materials and machining conditions, the G350T combines advanced milling and turning capabilities into a highly reliable platform that strengthens process control and boosts overall productivity.

At the core of the G350T’s performance is its robust and thoughtfully designed machine architecture. Grob has positioned the three linear axes in a distinctive arrangement that minimizes the distance between the guideways and the actual machining point. This construction greatly enhances rigidity, reduces vibration and ensures accurate cutting performance, even under heavy load conditions. The focus on stability is particularly beneficial for small-part machining where precision is paramount and the slightest disturbance can affect part tolerance and surface quality.

The G350T offers exceptional positioning flexibility thanks to the generous swivel ranges of its rotary axes—230 degrees in the A’-axis and a full 360 degrees in the B’-axis. This expansive motion envelope gives operators the freedom to tackle complex geometries, angled features and multi-sided machining tasks with ease. The horizontal spindle orientation further enhances performance by enabling the longest possible Z-travel path and ensuring efficient chip evacuation. With chips falling naturally out of the work area, machining remains clean, predictable and better suited for continuous or lights-out operations.

A major highlight of the G350T is its table, which has been specifically optimized for combined milling and turning applications. The rotary B-axis achieves speeds up to 1,200 rpm, allowing the machine to transition seamlessly between milling and turning within the same setup. This integration significantly reduces the need for secondary operations, shortens cycle times and improves part accuracy by eliminating errors associated with part repositioning.

One of the machine’s signature innovations is the Grob tunnel concept. This unique design allows even large or elongated components to be swiveled and machined within the working area without risk of collision—an advantage that becomes especially important when using long tools or producing parts with deep internal features. The tunnel structure maximizes usable space while maintaining excellent access and visibility for the operator.

The G350T delivers full five-axis versatility, supporting five-sided machining, simultaneous five-axis interpolation and Grob’s TRAORI-turning technology, which ensures precise cutting control across complex contours. This versatility makes the machine ideal for industries such as aerospace, medical, automotive, mold and die, and precision engineering—where small components often demand intricate geometries and tight tolerances.

In addition to its performance features, Grob has placed strong emphasis on ease of maintenance and long-term reliability. The compact design consolidates critical components for quick access, simplifying routine service and helping manufacturers reduce machine downtime. This thoughtful approach to maintainability reinforces Grob’s reputation for building machines that are not only powerful but also practical for real-world production environments.

With the G350T, Grob Systems continues to push the boundaries of mill-turn innovation, offering manufacturers a compact yet powerful solution for high-precision part production. The machine provides a combination of flexibility, stability and technological sophistication that supports consistent machining quality, improved process reliability and greater overall efficiency in modern manufacturing operations.