New SWR-TIGMIG Robot Unifies TIG and MIG Welding for Faster, Smarter Pipe Fabrication!

By Ashutosh Arora

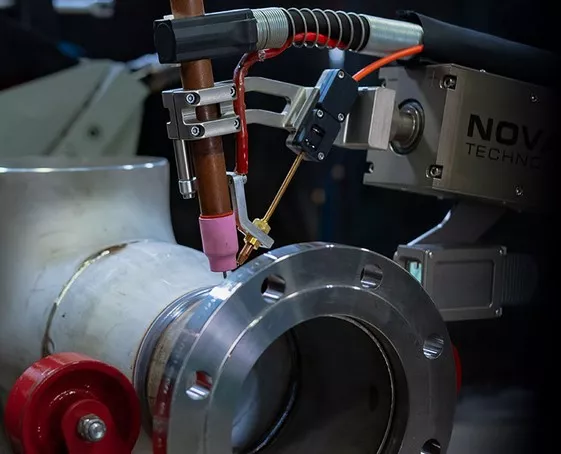

Novarc Technologies Inc. has introduced the SWR-TIGMIG, an advanced spool welding robot that merges two essential welding processes—TIG and MIG—into one fully autonomous, high-performance system. Designed specifically for the pipe fabrication industry, the new platform gives fabricators the ability to achieve X-ray-quality TIG root welds while maintaining MIG-level speed and throughput, marking a significant leap forward in automated welding efficiency.

One of the standout advantages of the SWR-TIGMIG is its ability to switch between TIG root passes and MIG fill passes in under 30 seconds. This rapid transition capability not only cuts production time dramatically but also enables shops to manage a wider variety of welding projects without sacrificing consistency or precision. By combining the strengths of both processes into a single workflow, fabricators can reduce setup complexity, improve process control, and streamline overall weld production.

Despite its powerful capabilities, the system maintains a compact footprint of just 4 by 4 ft., making it suitable for crowded shop floors and adaptable enough to integrate with up to four positioners. This flexibility allows shops to expand automation without major facility changes, supporting both small-scale operations and large-volume production environments.

The SWR-TIGMIG is equipped with a single-camera vision system that ensures clear weld visibility and accurate process monitoring. Its Luna user interface provides intuitive control over both TIG and MIG processes, supported by intelligent welding recipes and built-in process memory that help maintain repeatable, high-quality welds. To further enhance productivity, the system includes NovData for detailed data collection and process management, as well as NovSync for precise multipositioner synchronization.

With the launch of the SWR-TIGMIG, Novarc Technologies continues to push the boundaries of robotic welding automation—giving manufacturers a compact, versatile, and highly advanced solution for achieving superior weld quality with maximum efficiency.