How One Quality Manager Creates 5 PPAPs a Week by Herself Using 1factory

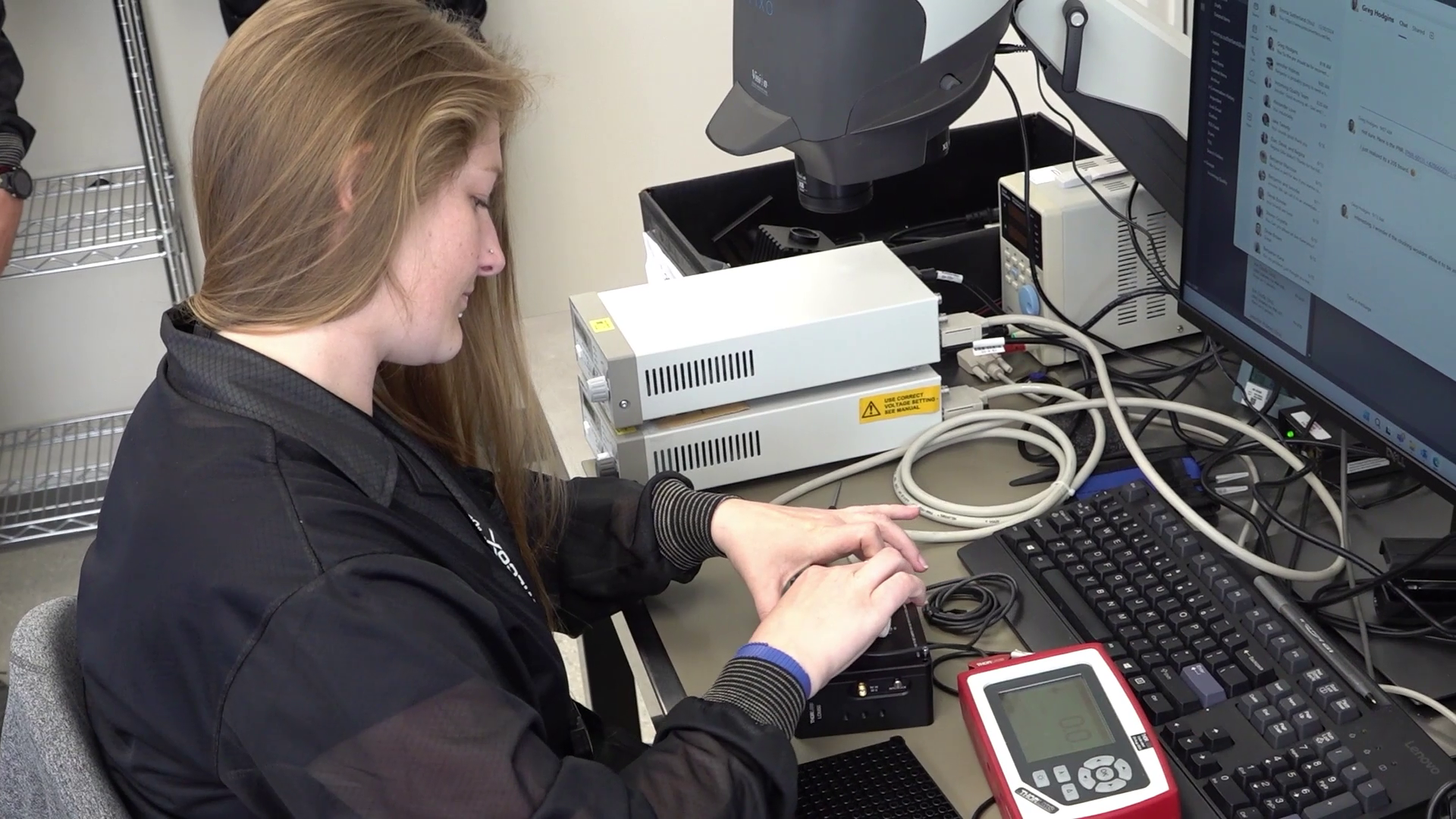

At J&L Manufacturing, an ISO 9001-certified job shop specializing in CNC machining, metal bending, and laser cutting, quality has always been at the heart of everything they do. Serving customers in the automotive, transit, and storage industries means every part must meet the highest standards. That responsibility falls largely on Christy Wiggam, J&L’s quality manager.

Earlier this year, Christy found herself struggling to keep up with an ever-growing PPAP workload. Completing a single PPAP could take her an entire week — from ballooning drawings by hand to entering every dimension into Excel and creating the PFMEA, Control Plan, and Process Flow manually. It was tedious, time-consuming work that slowed down production and limited how many jobs J&L could accept.

“As the only person handling PPAPs, I was always buried,” Christy recalls. “It took so much time to get one done that it felt like I could never catch up.”

Knowing that a new customer would soon require even more PPAPs, Christy decided something had to change. She began searching for a software solution to streamline the process. “I Googled ‘PPAP software’ and found a few options,” she says, “but most were part of large, complicated systems we didn’t need. Then I came across 1factory — it stood out because it was simple, user-friendly, and focused entirely on PPAP and inspection.”

After implementing 1factory, the transformation was immediate. What once took a full week now takes only one to two hours. “Let’s put it this way,” Christy says with a laugh, “I just finished up seven PPAPs this morning! Some of them just needed final touches, but still — that would have been impossible before.”

With 1factory, Christy’s process is now almost entirely automated. She uploads a drawing, and the software balloons every dimension and creates the inspection plan. From there, she matches operations with her saved PPAP templates, inspects the FAI directly in 1factory, and compiles everything in her PPAP log.

“When we first set up 1factory, I created templates for our standard processes — so now it’s just plug-and-play,” she explains. “It’s all so organized. I don’t have to dig through ten different folders to find what I need anymore.”

In just a few months, Christy has completed 168 PPAPs — averaging more than one per day. For a one-person team, that’s incredible efficiency. What was once a bottleneck has become one of J&L Manufacturing’s biggest strengths.

“I used to spend all my time chasing paperwork,” Christy says. “Now I can focus on improving quality, not just documenting it.”

With 1factory, J&L Manufacturing has turned an overwhelming process into a smooth, efficient workflow — proving that with the right tools, even a one-person quality team can operate at world-class speed.