Dürr Completes Turnkey Paint Shop for Škoda’s Vietnam Plant in Record Time!

By Ashutosh Arora

German engineering firm Dürr has successfully completed a turnkey paint shop for the Thanh Cong Group (TC Group) at its new Thanh Cong Viet Hung (TCVH) automobile plant in Quang Ninh, Vietnam. This milestone marks the first collaboration between Dürr and TC Group and supports the launch of Škoda automobile production in the country.

The TCVH plant, fully funded by TC Group, forms a crucial part of Vietnam’s broader strategy to develop a major automotive manufacturing hub in Quang Ninh. Spread across 36.5 hectares, the facility is designed for an annual capacity of up to 120,000 vehicles. Initially, the plant will produce Škoda models such as the Kushaq and Slavia, catering to the growing demand in the Vietnamese market. Strategically located near Haiphong Port, the facility enables efficient logistics for importing completely knocked down (CKD) kits from Pune, India, streamlining assembly and production operations.

In its first phase, the plant will operate at 13 jobs per hour, with scalability to 20 jobs per hour in the second phase, ensuring flexibility to meet increasing production volumes as market demand rises.

The completion of this project stands out as a remarkable achievement, considering the global challenges faced during its execution. Dürr managed to deliver the project within just 18 months—between November 2023 and July 2025—despite disruptions caused by material shortages, supply chain issues, and extreme weather conditions. This timely completion, while adhering to all technical and quality standards, demonstrates Dürr’s strong project management and engineering excellence.

In recognition of its outstanding performance and reliability, TC Motors honored Dürr China with the “Excellent Supplier” award. Commenting on this success, Wang Shuo, Project Manager at Dürr Paint Shop Systems Engineering (Shanghai) Co., Ltd., said, “A key factor in this achievement was the effective collaboration between the teams of Dürr China and Dürr Vietnam with TC Group.”

Technologically, the new paint shop is equipped with Dürr’s state-of-the-art RoDip E system for pretreatment and electrocoating. This innovative system uses programmable trolleys that allow each vehicle body to rotate and move independently, enhancing coating quality while minimizing chemical and energy consumption. By ensuring consistent coverage and precise control, RoDip E contributes significantly to both sustainability and efficiency.

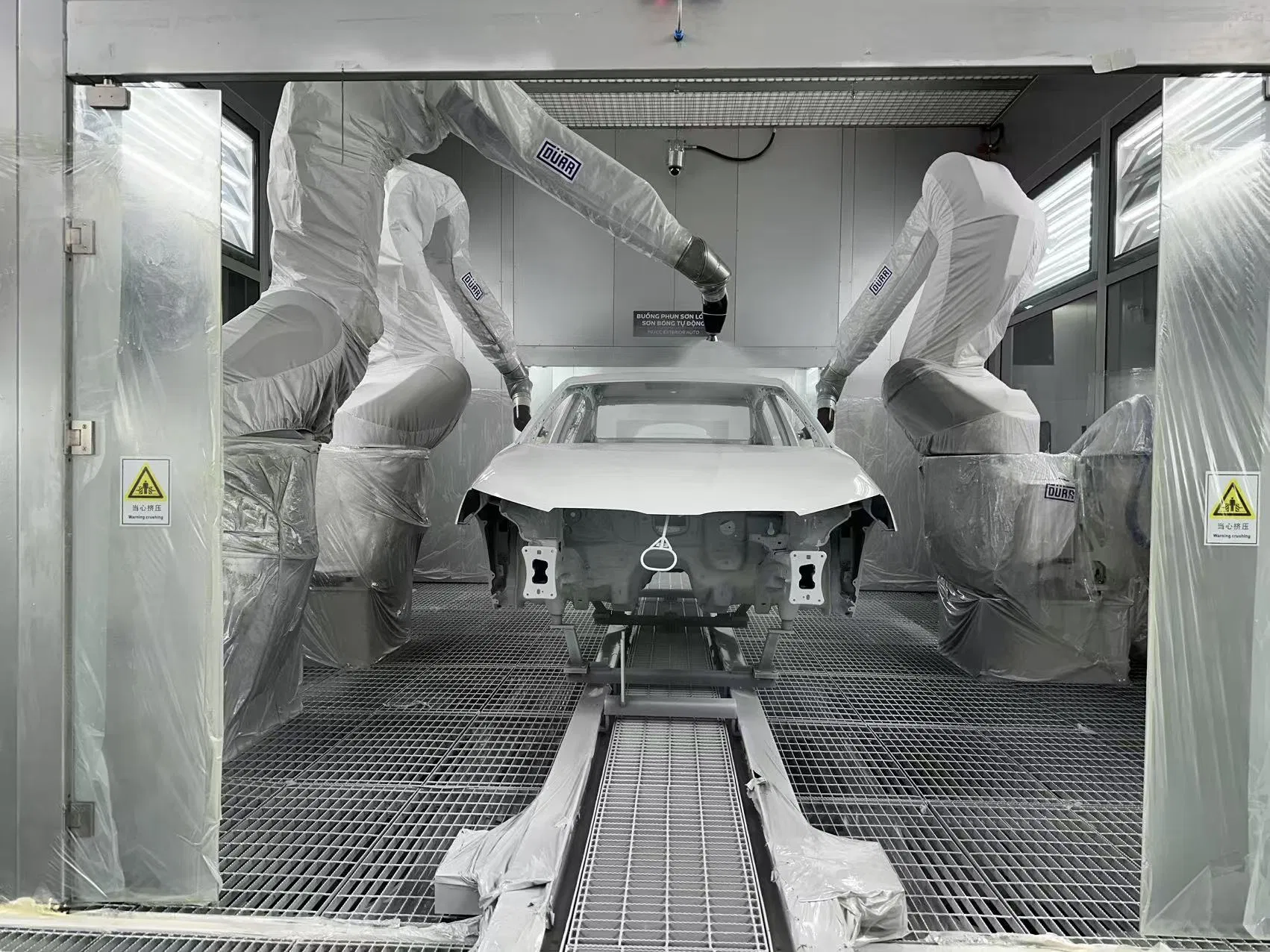

Additionally, the facility integrates both primer and clear-coat applications in the same spray booth—an intelligent design that optimizes investment costs and floor space. The plant is further equipped with sealing lines, seven automated painting robots, high-efficiency ovens, and a hot wax line to ensure durability and superior finish quality.

The successful completion of this project not only reinforces Dürr’s reputation as a global leader in turnkey paint shop solutions but also underscores Vietnam’s growing position in the global automotive manufacturing landscape. With Škoda’s entry into local production, the TCVH plant is poised to become a cornerstone of the country’s industrial and economic development.