Hybrid Manufacturing Technologies Global Enhances Military Manufacturing with Ambit Xtrude 3D Printing System!

By Ashutosh Arora

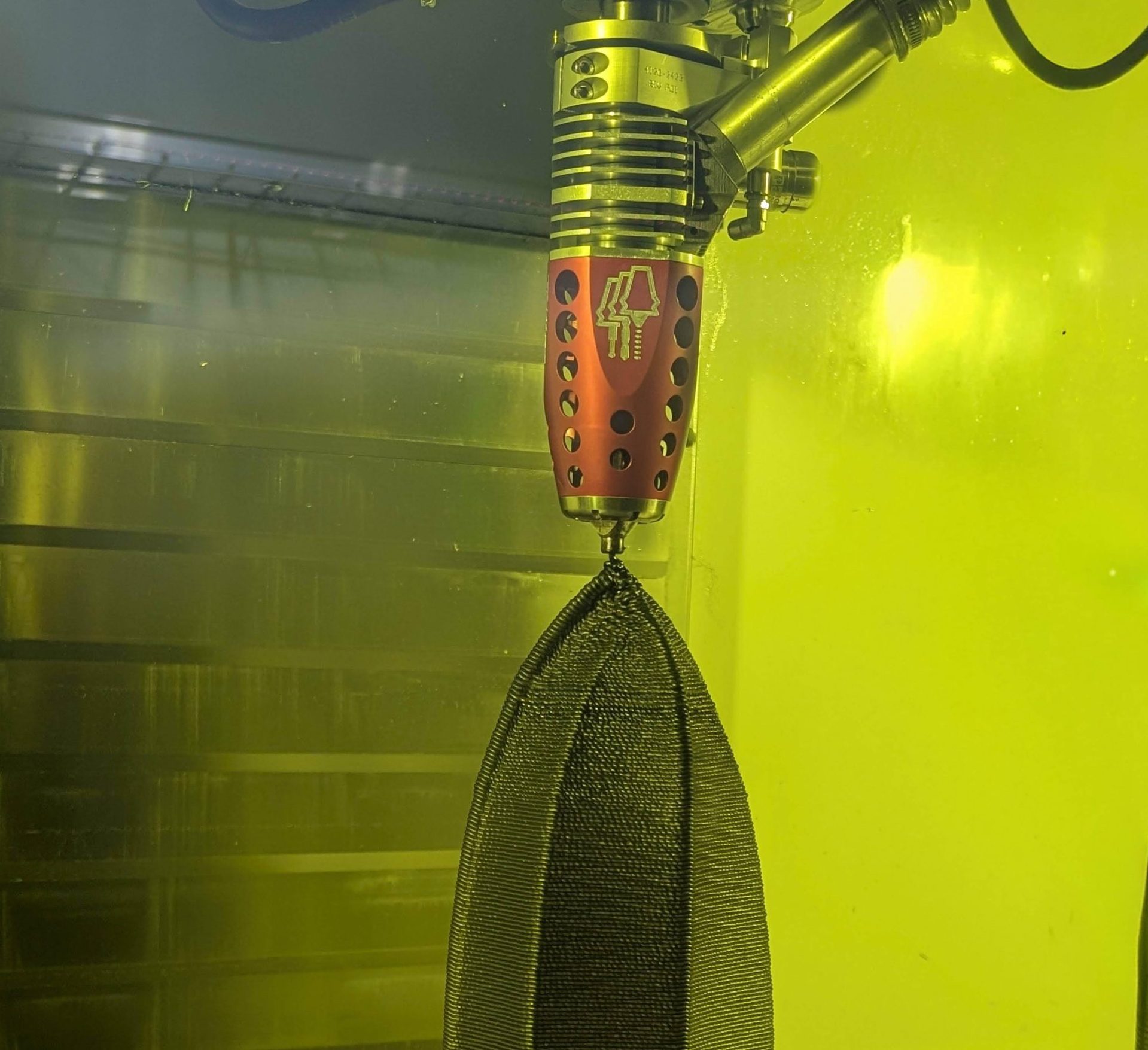

Hybrid Manufacturing Technologies Global has introduced the Ambit Xtrude polymer composite 3D printing system, a powerful new solution designed to accelerate military manufacturing and large-scale production. This pellet-fed material extrusion system seamlessly integrates with CNC machines, combining additive and subtractive manufacturing in one setup. Capable of achieving up to 2,000 times the volumetric deposition rates of standard desktop polymer printers, the Ambit Xtrude enables rapid production of meter-scale components such as tooling, fixtures, and drone hulls, all of which can be finished to precision using the same machine’s milling functions.

The system is engineered for simplicity, speed, and versatility, allowing users to switch between 3D printing and CNC machining in just a few minutes. During a recent naval exercise, the Ambit Xtrude was successfully integrated into an existing CNC machine owned by the U.S. Navy within a single day. Once operational, it produced drone boat hulls at a rate of over one per hour. Remarkably, military personnel with minimal training were able to operate the system efficiently, showcasing its intuitive design and suitability for high-demand defense environments.

Dr. Jason Jones, who led the integration at the Consortium for Advanced Manufacturing Research and Education (CAMRE) Advanced Manufacturing Facility at the Naval Postgraduate School in Monterey, California, emphasized the system’s dual benefits. “The dual purposing of CNC equipment for additive manufacturing and milling offers ease of use with significant cost and space effectiveness — key factors for success in this naval exercise,” he explained. Within the first day of operation, trained service members successfully produced a full drone boat hull segment and a custom carrying case insert for a critical metal component.

Lieutenant Colonel Michael Radigan of the Marine Innovation Unit, who collaborated with CAMRE and Fleetwerx on the project, noted the system’s strategic advantages in field conditions. “In advanced manufacturing exercises, time for learning new equipment is extremely compressed. By adding polymer capability to machines and interfaces that our service members already understand, we drastically reduce the time needed to deliver mission-critical readiness solutions,” he stated.

The Ambit Xtrude represents a significant leap forward in hybrid manufacturing technology. Its ability to retrofit existing CNC machines transforms conventional manufacturing setups into flexible hybrid production systems, allowing organizations to shift from traditional machining to additive manufacturing without major equipment overhauls. For the military, this translates into faster part replacement, enhanced field repair capabilities, and greater self-sufficiency in mission environments.

By combining additive and subtractive processes in one platform, Hybrid Manufacturing Technologies Global is redefining how manufacturing adaptability and efficiency are achieved. Through its collaboration with the Naval Postgraduate School and joint service units, the company is not only advancing defense manufacturing readiness but also setting new standards for hybrid production systems that can respond swiftly to evolving operational needs.