NCMT and BEL Engineering show how collaboration—and social media—are building a new talent pipeline on UK National Manufacturing Day

Thursday, 25 September 2025 — To mark UK National Manufacturing Day, NCMT and BEL Engineering are shining a spotlight on how manufacturers can grow their own next-generation talent by pairing hands-on training with modern 5-axis technology and meeting young people where they already are: on TikTok, Instagram and YouTube.

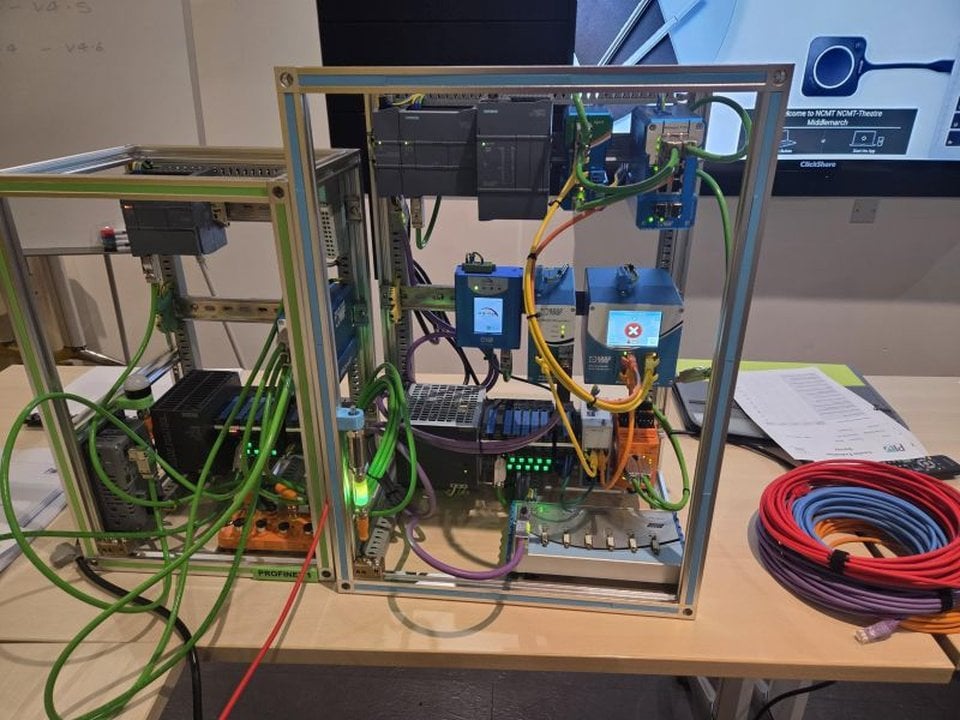

A 2025 Make UK study found the manufacturing sector faces 55,000 unfilled long-term vacancies, costing £6bn per year in lost output. Since the Apprenticeship Levy was introduced, apprenticeship starts are down 42%, intensifying shortages especially for SMEs. NCMT and BEL Engineering are working to reverse this trend with a partnership that equipped BEL’s Training Academy with an Okuma GENOS M460V-5AX 5-Axis Vertical Machining Center, giving apprentices an industry-realistic environment to develop job-ready skills.

This September, top UK Manufacturing technology provider NCMT welcomed three new apprentices to its Coventry-based team. BEL Engineering continue to add apprentices to their Training Academy.

Simon McLeod, Manufacturing Training & Development Lead at BEL Engineering, added: “Most of our future work is 5-axis, so our invest strategy in machinery matches reality of the equipment they will be using on the shop floor. Common controls, probing and offline programming mean learners build a transferable model of how jobs are really run, so what they practise in the Academy is what they’ll do once qualified, working on the best multi-axis machinery.”

“BEL Engineering previously struggled to recruit suitably skilled machinists, so they chose to build talent from the ground up,” said Andrew Skee, Sales Manager (Northeast & Scotland), NCMT. “By investing in their machining capabilities to help their apprentices and giving learners access to the best 5-axis technology, they’re creating engineers who can hit the ground running.”

What’s new is how the BEL Engineering Academy and NCMT have been blending real-world training with social media. Apprentices watch short, authentic videos of live machining set-ups, toolpaths and probing cycles from engineers across the UK and beyond, then apply those insights in the Academy, helping to familiarise them with the technology at their fingertips. It’s a powerful loop: inspiration online, application offline.

“They’re not only learning in the classroom, they’re seeing what their peers and engineers around the world are creating. It gives them inspiration and context for what these machines can achieve, which in turn boosts their confidence to try new approaches in our Academy.” said McLeod. “Social channels give them context for what’s possible and the confidence to attempt new approaches safely in our Academy.”

Chief Engineer Phil Westgarth summed it up: “If we want 5-axis capability on the shopfloor, we need 5-axis thinking in the classroom. The earlier we get apprentices thinking like engineers, the better.”

Callum Muir NCMT Apprentice said: “Social has turned our phones into a shared toolbox. When we have breaks, we show each other short videos—on aerospace, lightweight fixtures for automotive, tough Inconel valves for oil & gas, and precision implants for medical, it is really inspiring. Seeing real set-ups, gives us ideas we can aspire to do when we are fully qualified —from workholding and offsets to CAM tweaks—always with our trainers’ guidance. It doesn’t replace fundamentals; it accelerates them. Watching clips helps us picture what ‘good’ looks like across sectors, practise it safely on the machines, and build the confidence to take on more complex parts.”

Jonathan Smart, Managing Director of NCMT, said: “Young people find careers on their phones, so let’s use that to inspire them towards engineering. Short-form video is manufacturing’s new shop window. Paired with rigorous, on-the-ground training, it helps bridge the skills gap, speaks to future engineers in their language and attracts new recruits to a boundary-pushing industry. We deliver world-class manufacturing technology and work with partners to unlock its full capability; social media adds the spark and ambition apprentices need to excel.”

The collaboration between NCMT and BEL Engineering is more than a technology purchase; it’s a long-term investment in people. With cutting-edge 5-axis capability, a tailored training programme and a digital-first learning culture, apprentices are gaining the skills and confidence to thrive in modern engineering.

This is what a modern training ecosystem looks like: industry-realistic machines, social-powered learning and partners committed to the long game. Together, NCMT and BEL Engineering are not only machining parts—they’re machining possibility—and helping ensure a bright future for British manufacturing and engineering.