United Grinding Introduces Vision Laser Machine for Advanced Tool Processing!

By Ashutosh Arora

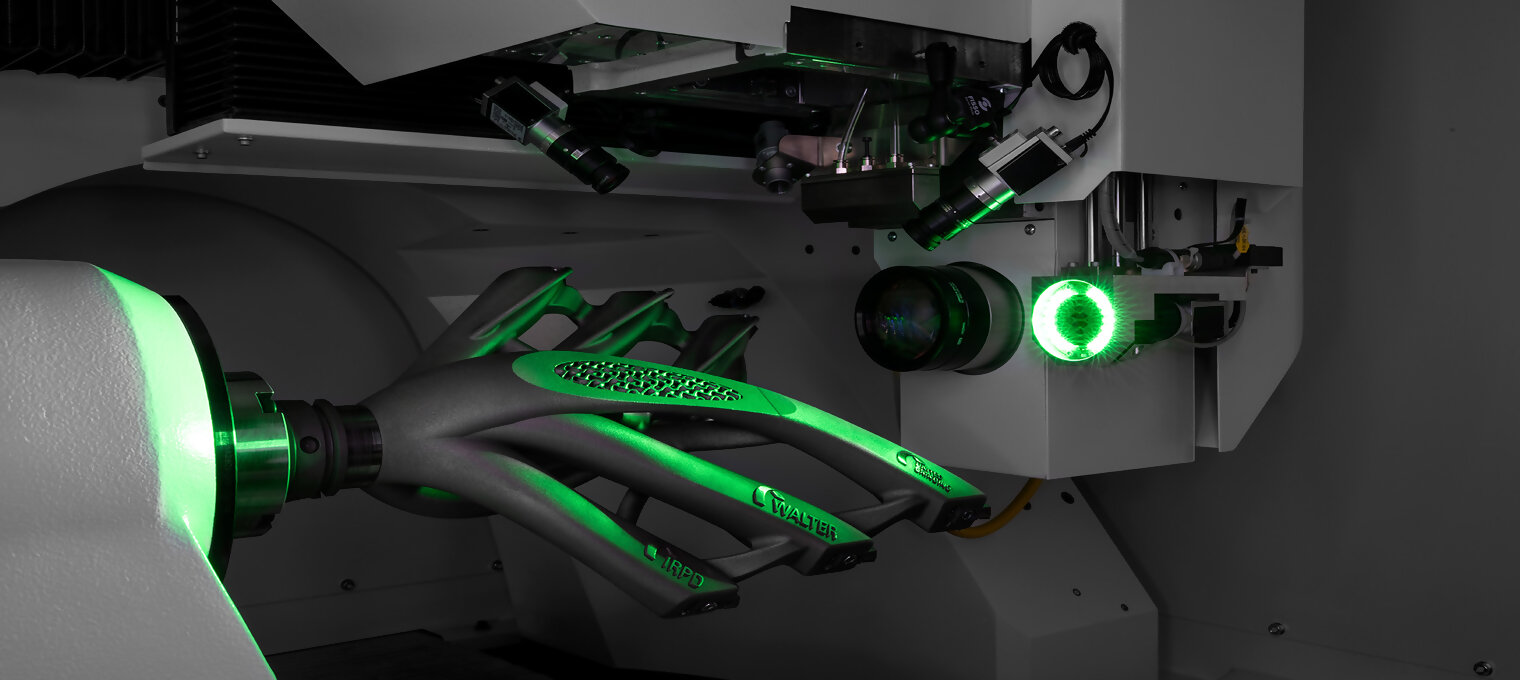

United Grinding North America Inc. has expanded its technology portfolio with the introduction of the Vision Laser machine, a system designed to deliver high-precision tool processing for brazed tools with stringent quality requirements. Built on the proven Helitronic Vision platform, the Vision Laser provides manufacturers with a new alternative to traditional methods like wire erosion, offering faster speeds, superior surface finishes, and reduced consumable usage.

The Vision Laser is engineered for versatility, supporting a wide range of cutting tool materials. It is capable of processing polycrystalline diamond (PCD), chemical vapor deposition (CVD) diamond, monocrystalline diamond (MKD), and carbide. By leveraging industrial laser technology, the machine can produce chip- and crack-free cutting edges, handle complex geometries, and operate without consumables — advantages that set it apart from conventional wire EDM systems.

Traditionally, brazed PCD tools have been produced using wire erosion, a process that, while effective, comes with inherent challenges. Wire EDM consumes wires and coolants, adds cost, and can lead to risks such as grain breakage. Additionally, the method places limits on creating intricate geometries. The Vision Laser overcomes these drawbacks by allowing production in a single clamping setup, enabling high cutting speeds and achieving consistently excellent surface finishes. This streamlined process not only improves productivity but also enhances the quality and repeatability of the final tool.

At the heart of the Vision Laser’s ease of adoption is its software, GTR ProfDia Laser. Developed with a familiar interface for existing United Grinding users, the software closely mirrors the widely adopted GTR ProfDia Erosion package used for EDM processes. This similarity enables operators who are already experienced with EDM systems to make a smooth transition to laser-based tool processing, reducing the learning curve and supporting faster integration into production environments.

The Vision Laser also underscores United Grinding’s commitment to innovation within the tool grinding and processing sector. By expanding its technology offerings beyond grinding and erosion into industrial laser processing, the company is positioning itself as a comprehensive solutions provider. The Vision Laser complements the rest of the Helitronic product family, giving manufacturers a broader toolkit for addressing the evolving demands of precision machining.

For industries where brazed tools play a critical role — such as aerospace, automotive, medical, and electronics — the Vision Laser represents a leap forward. Its ability to process diamond and carbide materials with minimal waste, while delivering cutting edges of superior quality, supports both high-performance manufacturing and long-term sustainability goals.

Reliability and productivity are also central to the Vision Laser’s design. By removing consumable dependencies and minimizing risks of tool damage during processing, the machine offers consistent performance for long-term use. These capabilities make it especially valuable for manufacturers seeking to reduce operational costs while increasing throughput and maintaining exacting quality standards.

With the launch of the Vision Laser, United Grinding North America is reshaping the way brazed tools are produced. By combining laser precision with proven platform stability and intuitive software, the machine empowers manufacturers to achieve higher productivity, improved tool performance, and greater flexibility in handling advanced materials.