Haskell Co. Expands Capabilities with New Miscellaneous Metals Shop in Jacksonville!

By Ashutosh Arora

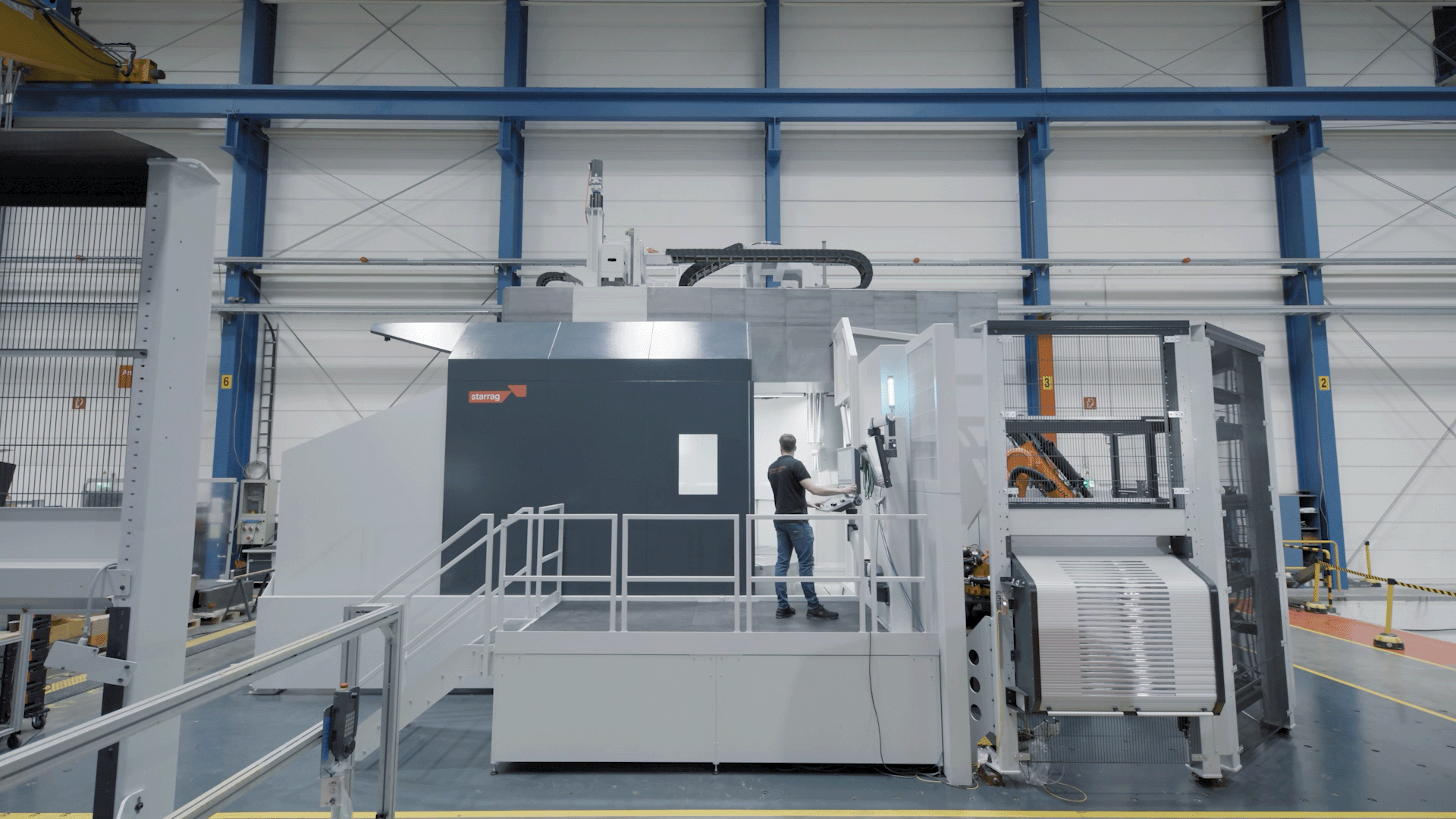

Haskell Co., a leading integrated design, engineering, and construction firm, has marked another milestone in its growth by opening a state-of-the-art miscellaneous metals shop at its 30-acre Jacksonville, Florida campus. The 20,000-sq.-ft. facility was officially inaugurated in August 2025, strengthening the company’s in-house fabrication capabilities and reinforcing its commitment to efficiency, precision, and innovation.

The new shop is designed to meet the growing demand for high-quality metal fabrication in construction projects across Florida and beyond. Equipped with a stair stringer fabrication machine, CNC pipe and tube coping systems, a powerful 20-kW CNC fiber laser, and a laser layout projection system, the facility integrates modern manufacturing technologies that significantly reduce lead times while enhancing accuracy and consistency. To support production flexibility, the shop also includes 10 fully outfitted welding stations, enabling Haskell to take on diverse fabrication requirements ranging from custom components to high-volume project needs.

By expanding its fabrication footprint, Haskell aims to gain tighter control over project schedules and quality assurance. The addition of the fiber laser, with its advanced cutting capabilities, allows the company to process a wide variety of materials and thicknesses with precision, opening opportunities for more complex design features and efficient part nesting. Similarly, the laser projection system streamlines layout and assembly processes, minimizing manual error and increasing throughput.

According to company leaders, the shop represents a key investment in both people and technology. The facility’s layout prioritizes workflow efficiency, with material handling systems designed to reduce bottlenecks and maximize productivity. The inclusion of automated equipment complements the skill sets of Haskell’s fabricators, enabling them to focus on craftsmanship while leveraging cutting-edge tools for speed and accuracy.

The shop’s capacity will also help Haskell support larger and more complex projects without over-reliance on external suppliers. In an industry where supply chain volatility and labor shortages can disrupt timelines, having in-house capabilities provides resilience and a competitive edge. This aligns with Haskell’s broader strategy of vertically integrating its operations to deliver turnkey solutions for clients.

Beyond immediate project benefits, the new facility reflects Haskell’s long-term vision of sustainable and scalable growth. The company has emphasized its focus on leveraging digital tools, automation, and lean manufacturing practices to reduce waste and energy consumption. The investment in advanced fabrication technologies not only enhances productivity but also aligns with broader environmental and sustainability goals by optimizing resource use.

The opening of the miscellaneous metals shop also signals a boost to local employment. By creating skilled fabrication roles and offering opportunities for training in advanced CNC and laser technologies, Haskell is contributing to the development of a stronger manufacturing workforce in Jacksonville.

For over 75 years, Haskell has been recognized for combining architecture, engineering, and construction expertise to deliver innovative solutions across multiple industries, including manufacturing, food and beverage, healthcare, and commercial development. With the addition of its new metals shop, the company further strengthens its ability to execute projects with greater speed, precision, and control—setting a new benchmark for integrated design-build services.