Sheet Metal Fabrication System Integrates Seven Functions!

By Ashutosh Arora

Prima Power has introduced the Shear Genius, an advanced all-in-one sheet metal fabrication system designed to streamline operations and improve efficiency across manufacturing environments. By integrating seven core functions—loading, punching, forming, threading, marking, shearing, and part sorting—the system provides manufacturers with a compact, automated solution that reduces handling time, minimizes waste, and enhances overall productivity.

At the heart of the Shear Genius is its use of servo-electric technology, which delivers sustainable performance by lowering energy consumption and eliminating oil waste. This technology not only reduces the system’s environmental footprint but also cuts operational costs for manufacturers aiming to meet modern sustainability standards. By minimizing raw material usage, the system contributes to leaner and more eco-friendly production processes.

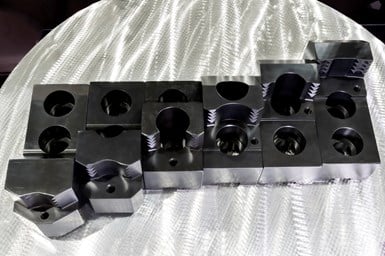

The Shear Genius is equipped with smart nesting capabilities that optimize sheet layouts, helping manufacturers maximize material utilization and reduce scrap. Rapid sheet loading further accelerates cycle times, while programmable shearing ensures precise cuts tailored to each application. With a capacity to handle up to 384 tools, the system offers unmatched versatility, enabling quick adaptation to different product requirements and industrial sectors.

One of the defining strengths of the Shear Genius is its suitability for high-mix, low-volume production environments. The integration of multiple fabrication functions into a single platform eliminates the need for several standalone machines, reducing floor space requirements and simplifying workflow management. For manufacturers facing increasing demand for flexibility and quick turnaround, the Shear Genius provides a powerful advantage.

Ease of use and maintenance have also been prioritized in the system’s design. The operator-friendly interface allows for efficient setup and control, while the automated features reduce manual intervention. This design not only improves safety and consistency but also helps manufacturers address workforce challenges by making the equipment more accessible to operators with varying skill levels.

Automation support is a key feature of the Shear Genius. By combining part sorting with scratch-free processing, the system ensures that finished components meet strict quality requirements. Automated handling reduces the risk of errors, while the smooth processing capabilities protect surface finishes, an increasingly important factor for industries such as automotive, electronics, and consumer goods where high aesthetic and functional standards are required.

With its blend of advanced technology and integrated processes, the Shear Genius is positioned as a comprehensive solution for manufacturers seeking efficiency, precision, and sustainability. It supports a broad range of applications across diverse sectors, from general sheet metal fabrication to specialized industries that require high-quality, consistent output.

By bringing together seven fabrication processes into one cohesive system, Prima Power has effectively redefined what a modern sheet metal fabrication line can achieve. The Shear Genius not only increases throughput and reduces waste but also empowers manufacturers to align with evolving demands for smarter, greener, and more automated production.