GROB Machine Tools UK Ltd has announced the availability of its G440 with PSS-R1800, a high-performance horizontal machining center designed to enhance production efficiency. This showroom model is equipped with cutting-edge features aimed at optimizing manufacturing processes.

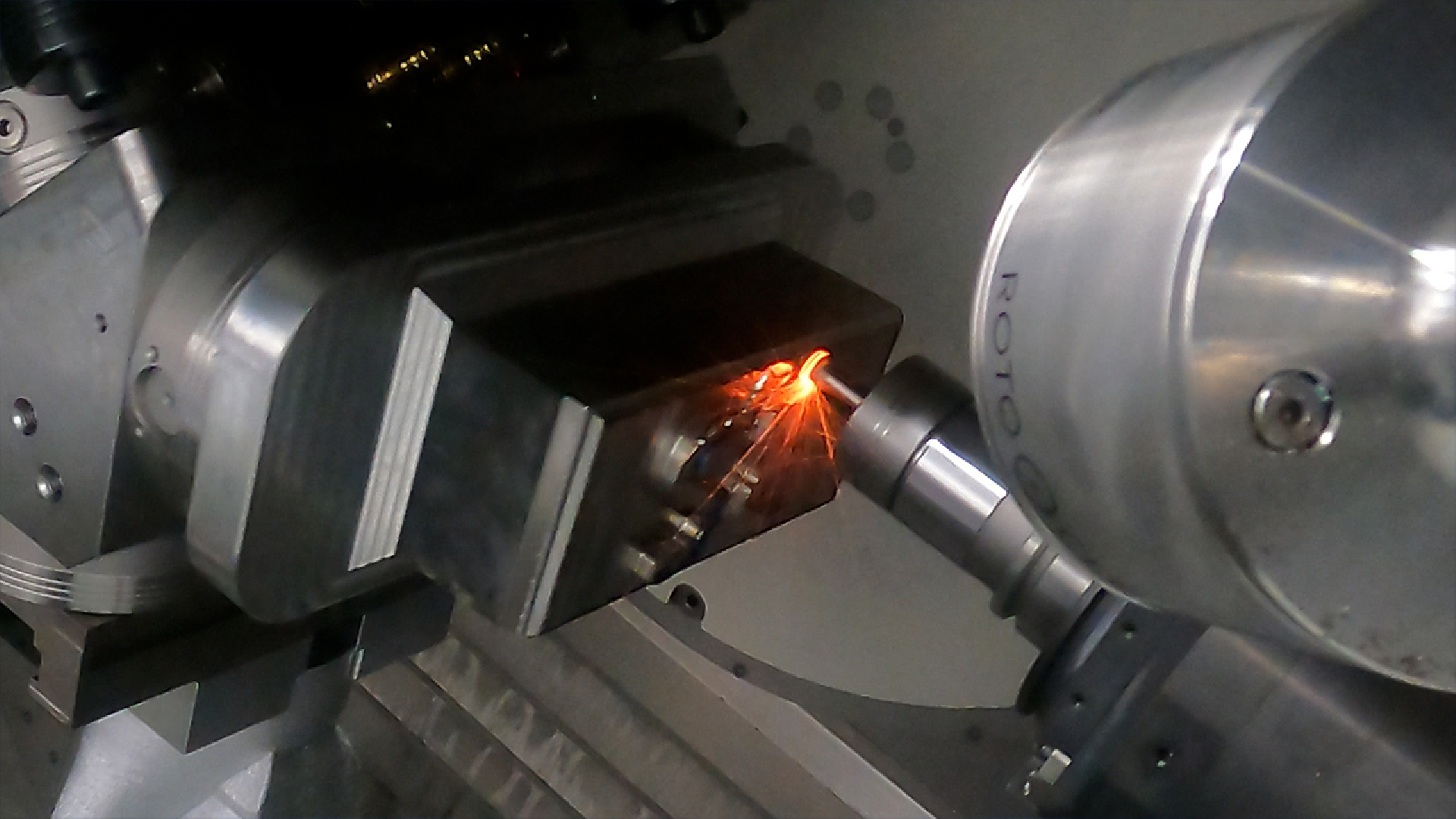

The GROB G440 is engineered with a 4-axis horizontal machining center, powered by the Siemens Sinumerik ONE control system. It boasts a motorized spindle with an HSK63 interface capable of reaching 16,000 rpm, ensuring high-speed and precise operations. Additionally, it comes with a substantial tool capacity of 167 tools, providing versatility for various manufacturing tasks.

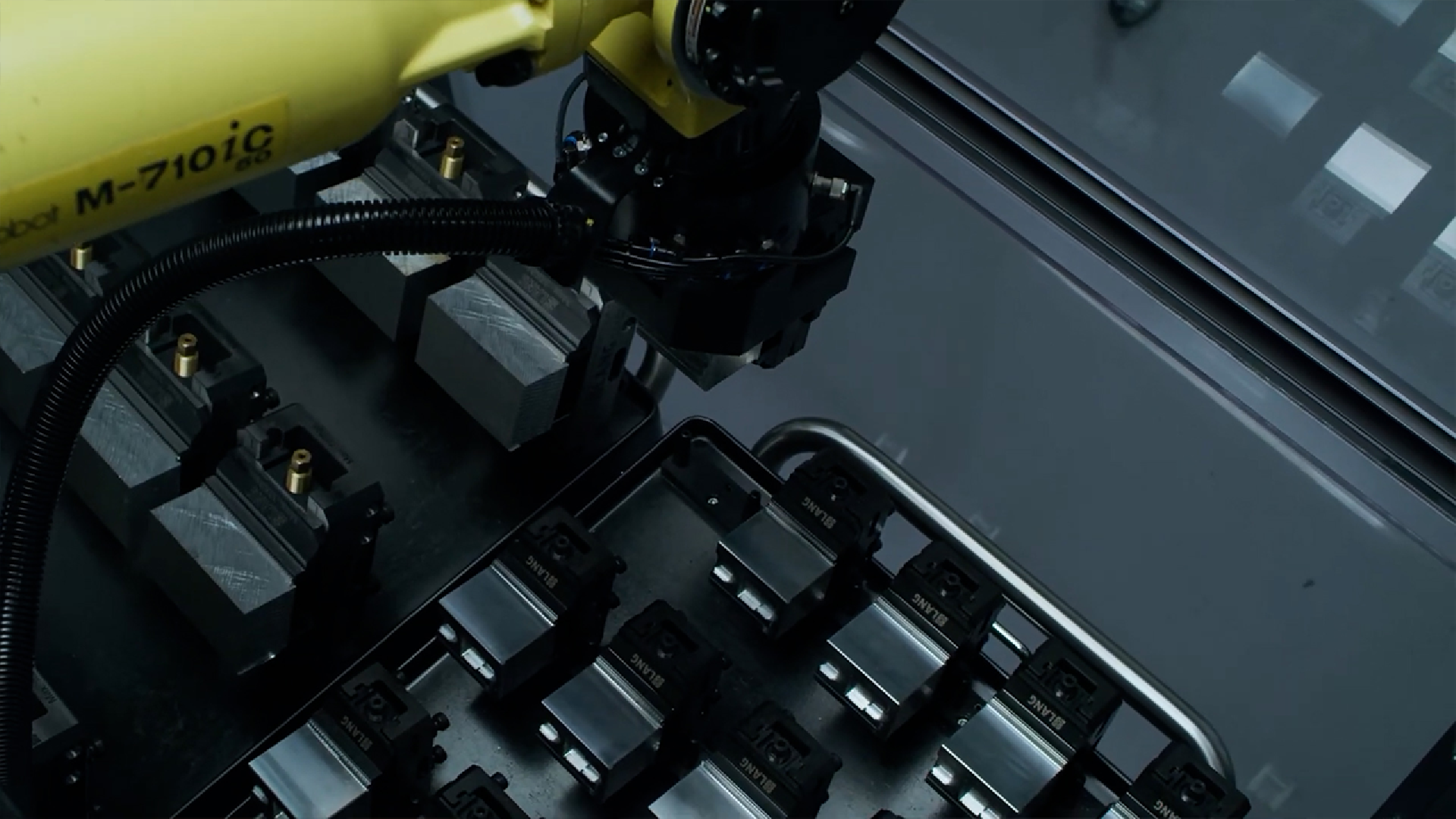

The machine’s pallet storage system can accommodate up to 10 locations, each sized at 500 x 630 mm. This feature, alongside the Blum laser tool measuring system, enhances efficiency by reducing downtime and ensuring accurate measurements. The internal coolant pressure system operates at 40 bar, facilitating optimal cutting conditions and prolonging tool life.

GROB Machine Tools is positioning the G440 as an ideal solution for manufacturers seeking aggressive pricing on a robust production tool. With the manufacturing industry’s continuous demand for improved efficiency and precision, this machine is set to meet the needs of industrial operations looking for reliable performance.

Interested parties are encouraged to contact GROB Machine Tools UK Ltd for further information and to explore how this machining center can be integrated into existing production lines to maximize output and precision.