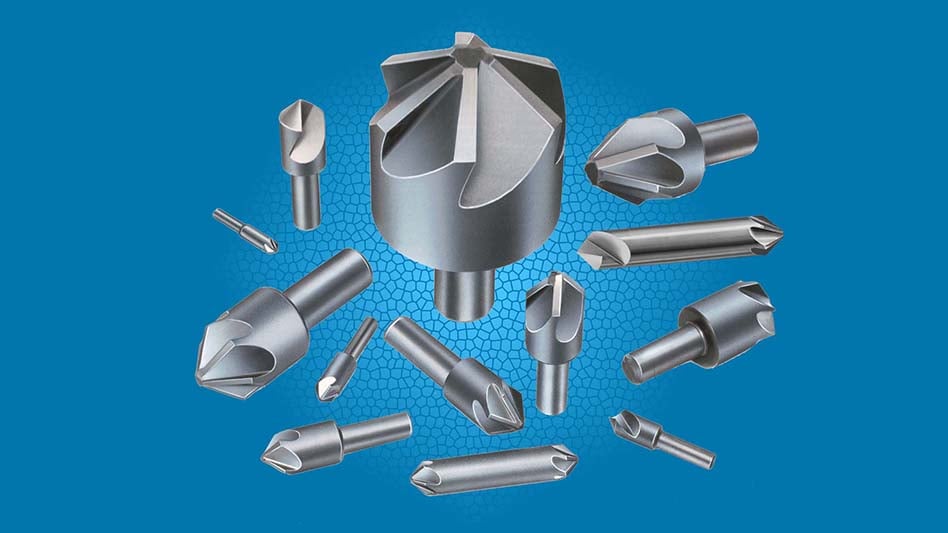

Severance Countersinks Minimize Vibration for Smoother, More Accurate Machining!

By Ashutosh Arora

Severance Tool Industries Inc. has developed a versatile line of countersinks specifically designed to reduce machining vibrations and deliver superior surface finishes. These tools stand out for their staggered cutting edge geometry, which effectively minimizes resonant (harmonic) vibrations—one of the primary causes of chatter during countersinking operations.

Unlike traditional symmetrical countersinks that often amplify vibration frequencies, Severance countersinks feature a chatterless design that breaks up harmonic resonance. While this design doesn’t eliminate the natural frequency of the machining system, it removes tool geometry as a contributor, resulting in smoother operation and enhanced dimensional accuracy across a wide range of materials and applications.

The product range is comprehensive, with options including one-, four-, and six-flute designs available in high-speed steel and carbide, as well as configurations with pilots, drill points, and custom features. Tool sizes span from 1/8″ to 3″, and nearly any centerline angle can be specified, making them adaptable to nearly all countersinking needs.

Severance’s offerings include:

- 3N1 Drill Points – Designed to help creative tool engineers reduce costs by combining multiple operations into one tool.

- CNC-K Precision Countersinks – Ideal for use in CNC and other preset tooling systems where repeatability and precision are critical.

- Stop Countersink Systems – Engineered for the aircraft industry, especially for use with handheld power tools to accurately countersink rivet holes.

- Custom & Special Tools – Tailored solutions that combine countersinks with drills, steps, pilots, radii, or other specialized shapes to suit unique applications.

With a focus on performance and versatility, Severance countersinks are engineered to meet the demands of modern manufacturing environments—reducing vibration, improving tool life, and delivering cleaner, more consistent results. Whether in aerospace, automotive, or general manufacturing, these countersinks provide a reliable solution for precision holemaking.